Method for preparing metallic ion doping nano bismuth oxide

A technology of nano-bismuth oxide and metal ions, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of unreported research on photocatalysts, and achieve the effects of high production costs, easy-to-obtain raw materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

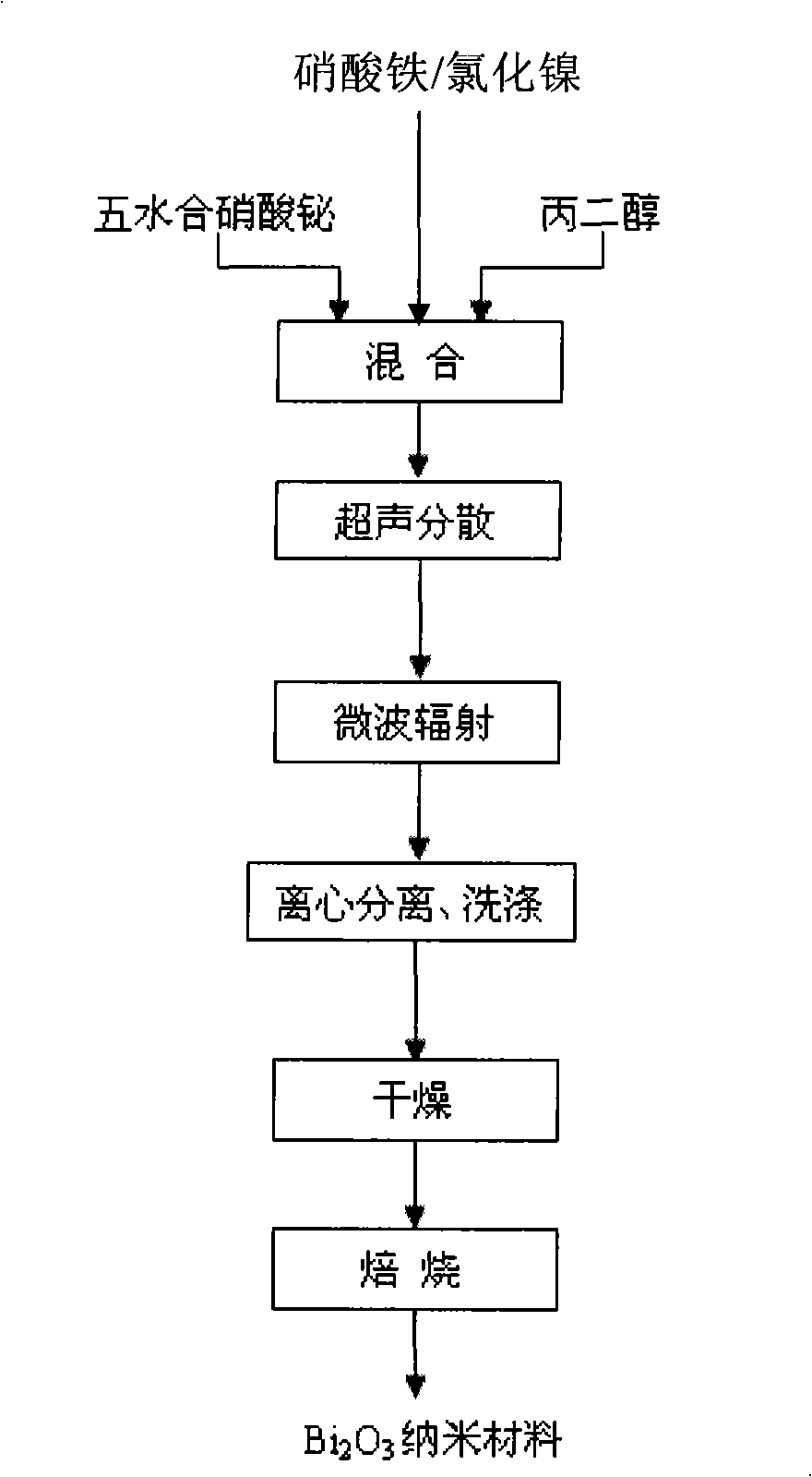

[0026] Embodiment 1 prepares the method for doping metal ion bismuth oxide

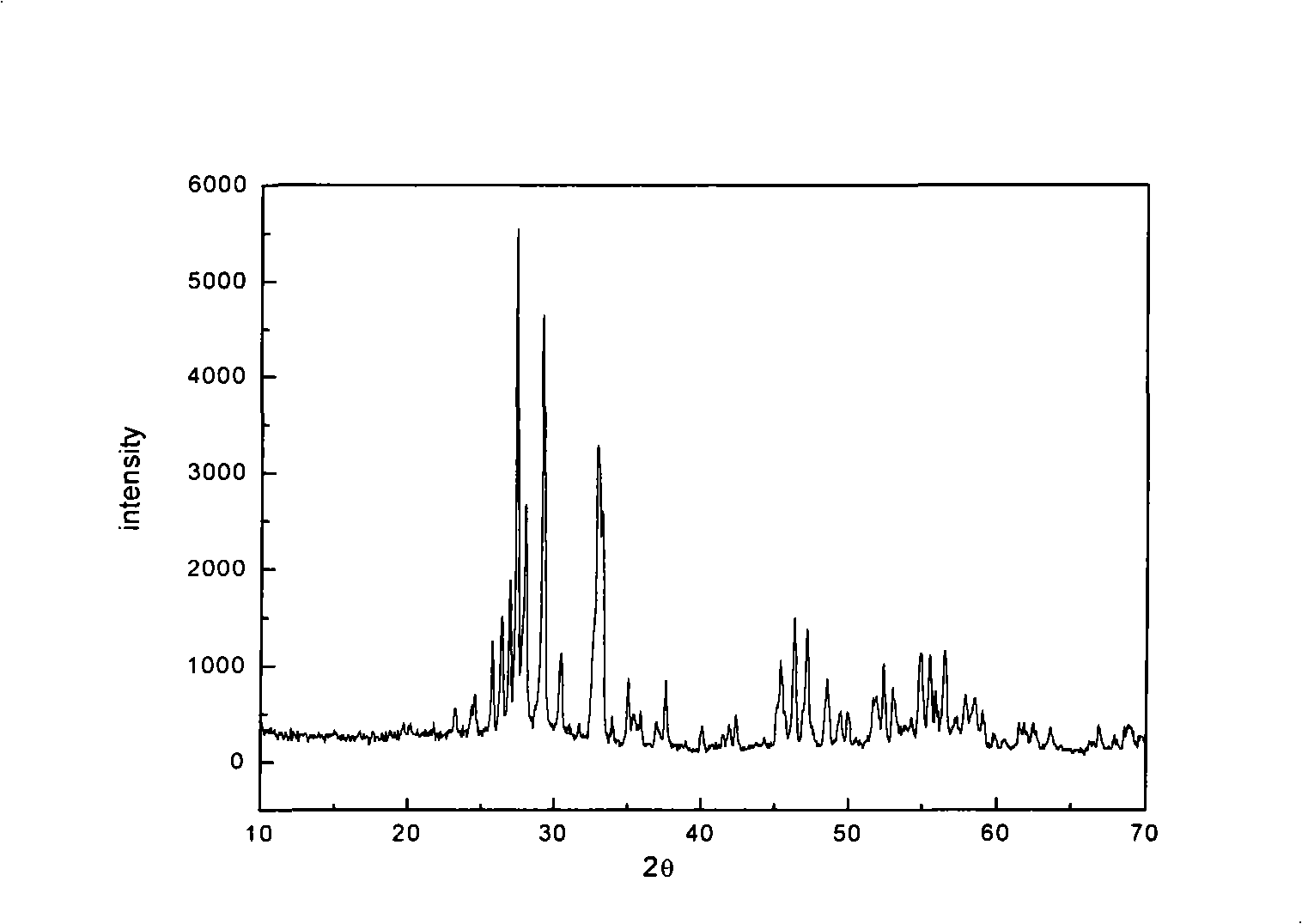

[0027] Accurately weigh 3.65g of bismuth nitrate pentahydrate, measure 50ml of ethylene glycol (ethylene glycol is enough to ensure that the bismuth nitrate is completely dissolved), mix the two in a beaker, and ultrasonically disperse for 30 minutes until the bismuth nitrate is completely dissolved, then add ferric nitrate Solution (C (Fe3+) : C (Bi3+) <20:1). Then above-mentioned mixed solution is transferred in the 250ml round-bottomed flask, is placed in the microwave oven that is connected with reflux device and carries out microwave reaction, microwave power is 360W, microwave radiation 8 minutes (every 2 minutes, interval 1 minute, totally 4 times) . After the reaction, the product was collected, centrifuged, and washed three times with deionized water and absolute ethanol. Dry at 80°C for 6h. Calcined at 500°C for 2h to obtain bismuth oxide product.

[0028] The preparation process of th...

Embodiment 2

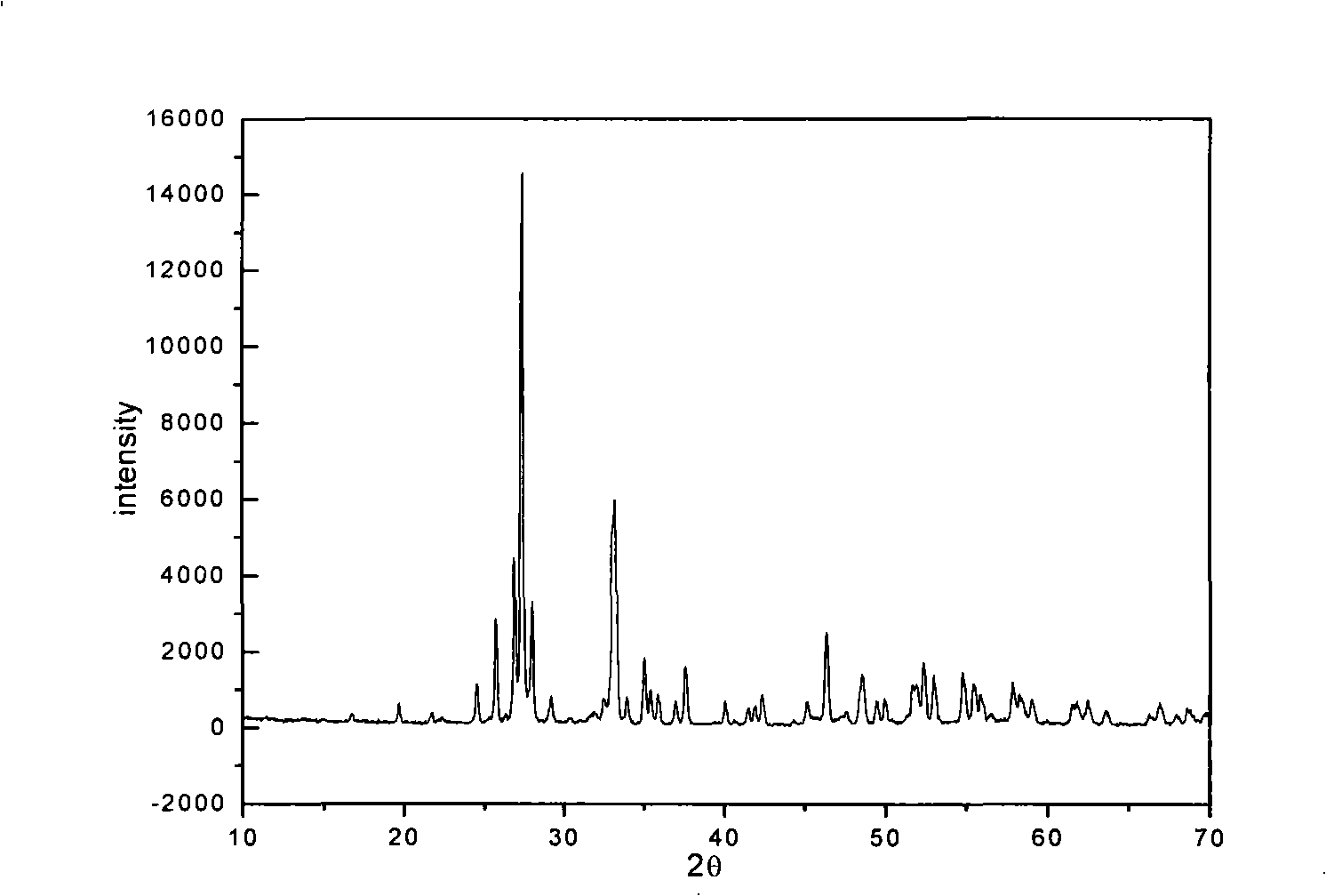

[0031] Accurately weigh 3.65g of bismuth nitrate pentahydrate, measure 50ml of ethylene glycol (ethylene glycol is enough to ensure that the bismuth nitrate is completely dissolved), mix the two in a beaker, and ultrasonically disperse for 30 minutes until the bismuth nitrate is completely dissolved, then add chloride Nickel solution (C (Fe3+) : C (Bi3+) <20:1). Then above-mentioned mixed solution is transferred in the 250ml round-bottomed flask, is placed in the microwave oven that is connected with reflux device and carries out microwave reaction, microwave power is 360W, microwave radiation 8 minutes (every 2 minutes, interval 1 minute, totally 4 times) . After the reaction, the product was collected, centrifuged, and washed three times with deionized water and absolute ethanol. Dry at 80°C for 6h. Calcined at 500°C for 2h to obtain bismuth oxide product.

[0032] The preparation process of this method is shown in figure 1 .

[0033] The XRD spectrum pattern of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com