Vinyl fluoride-based copolymer binder for battery electrodes

A technology based on fluorine-based copolymers and vinyl fluoride, which can be used in battery electrodes, circuits, electrical components, etc., and can solve problems such as resin hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

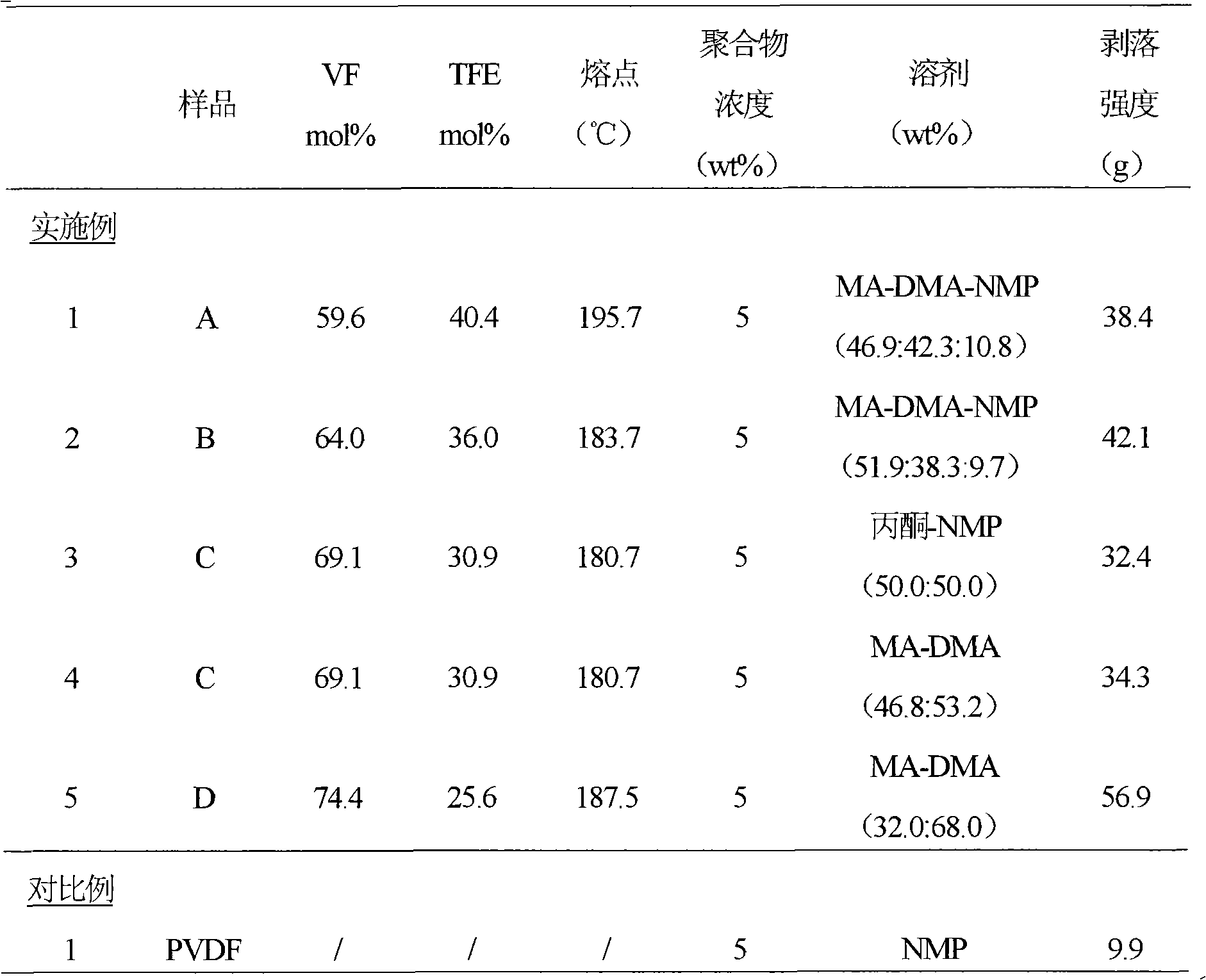

[0032] Examples 1 to 5, Comparative Example 1

[0033] Bond Strength Evaluation Test

[0034] After the organosol of the resin was prepared by mixing 5wt% of the vinyl fluoride-based copolymer or PVDF powder shown in Table 1 with an organic solvent, 5wt% of ketjen black was mixed to form a paste. The paste was coated on the frosted surface of aluminum foil (5cm×10cm) with a thickness of 15 μm, the coated surface of the aluminum foil was clamped to another aluminum foil of the same size, and the coated paste was spread by hand through a film applicator. Expand. The thickness of the sample was 120 μm. The smears were dried in a vacuum desiccator (LCV-232 from Tabai Espec) at 190°C for 3 hours. Afterwards, test samples of 1 cm x 5 cm were cut and used for testing of bond strength.

[0035] Bond strength was determined by a peel strength test in a 180 degree direction. The results are listed in Table 1. The bond strength of the tested samples was compared with samples prep...

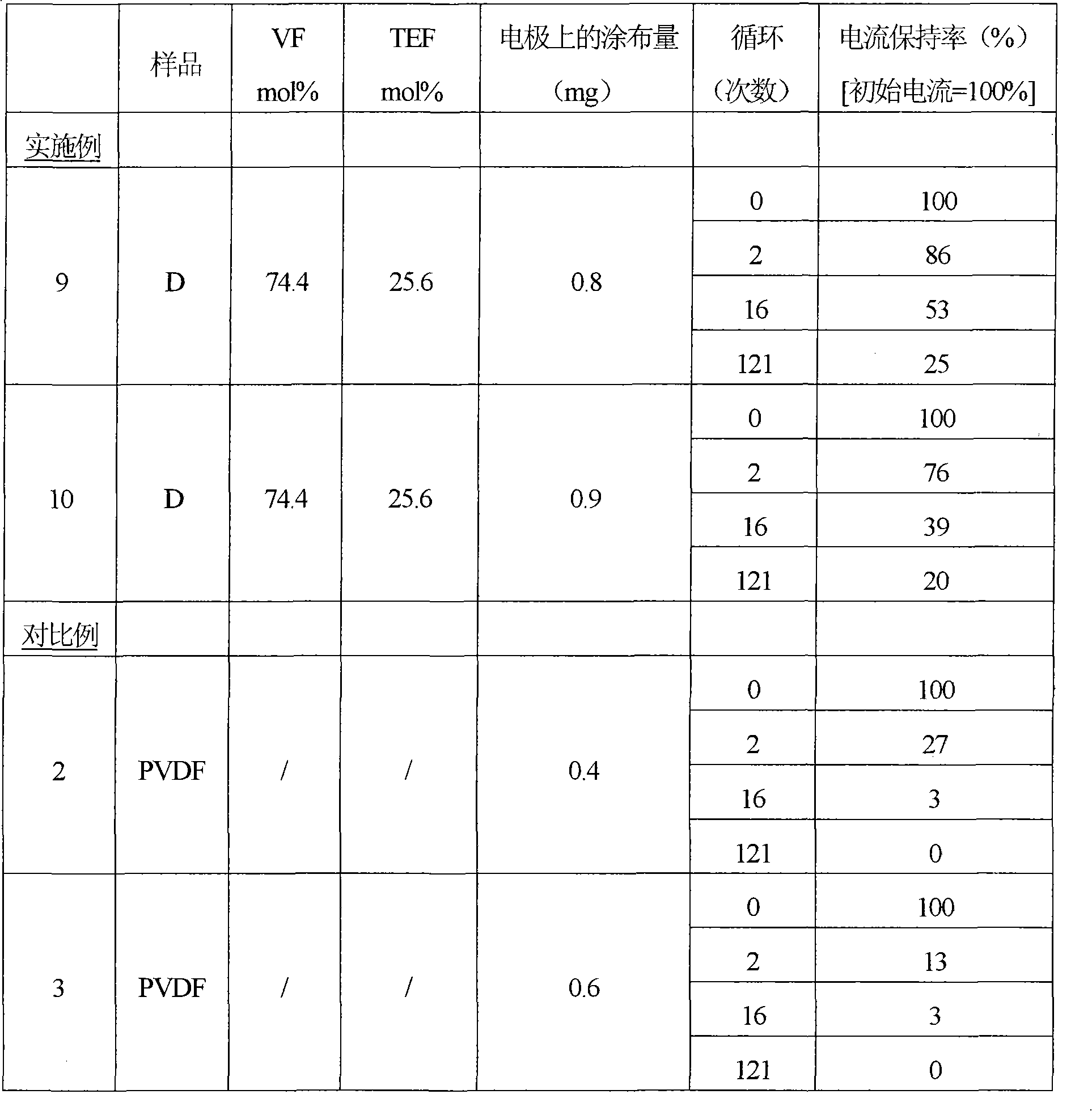

Embodiment 9 to 10, comparative example 2 to 3

[0045] Electrochemical test:

[0046] The paste for the bond strength test was coated on one side of an aluminum foil (0.5 cm×5 cm) with a thickness of 15 μm and dried at 190° C. for 3 hours. This sample was used as a test electrode, and the stability of the electrode was determined by cyclic voltammetry. The results are listed in Table 3.

[0047] A comparison of the current values at 3.50 V in each cycle shows that there is a decrease in current both in the examples and in the comparative examples. The reason for this phenomenon is assumed to be the LiPF in the electrolyte solution 6 Fluorination of aluminum foil forms an inactive film with low electrical conductivity, resulting in increased electrical resistance. However, there were significant differences in this propensity for reduction. For PVDF, the current decreases to about 30% in the second cycle, then decreases continuously to a few percent and becomes practically zero after 121 cycles. However, for the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com