Gas-liquid two-phase working substance coupled vibrations type thermo-acoustic engine

A thermoacoustic engine, coupled vibration technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc. Low efficiency and other problems, to achieve flexible and convenient acoustic impedance characteristics, avoid sliding sealing problems, and improve the effect of sound power output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

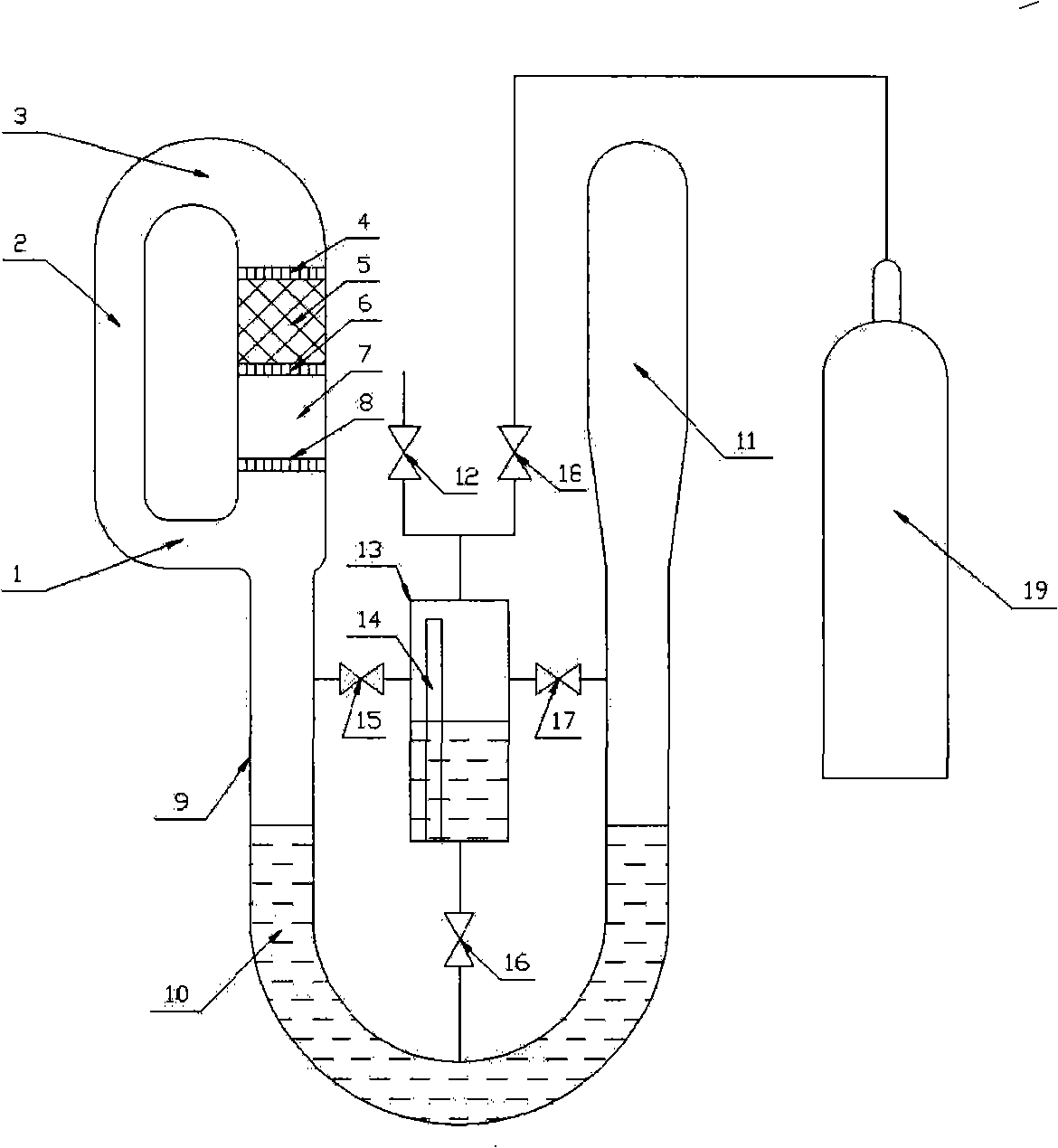

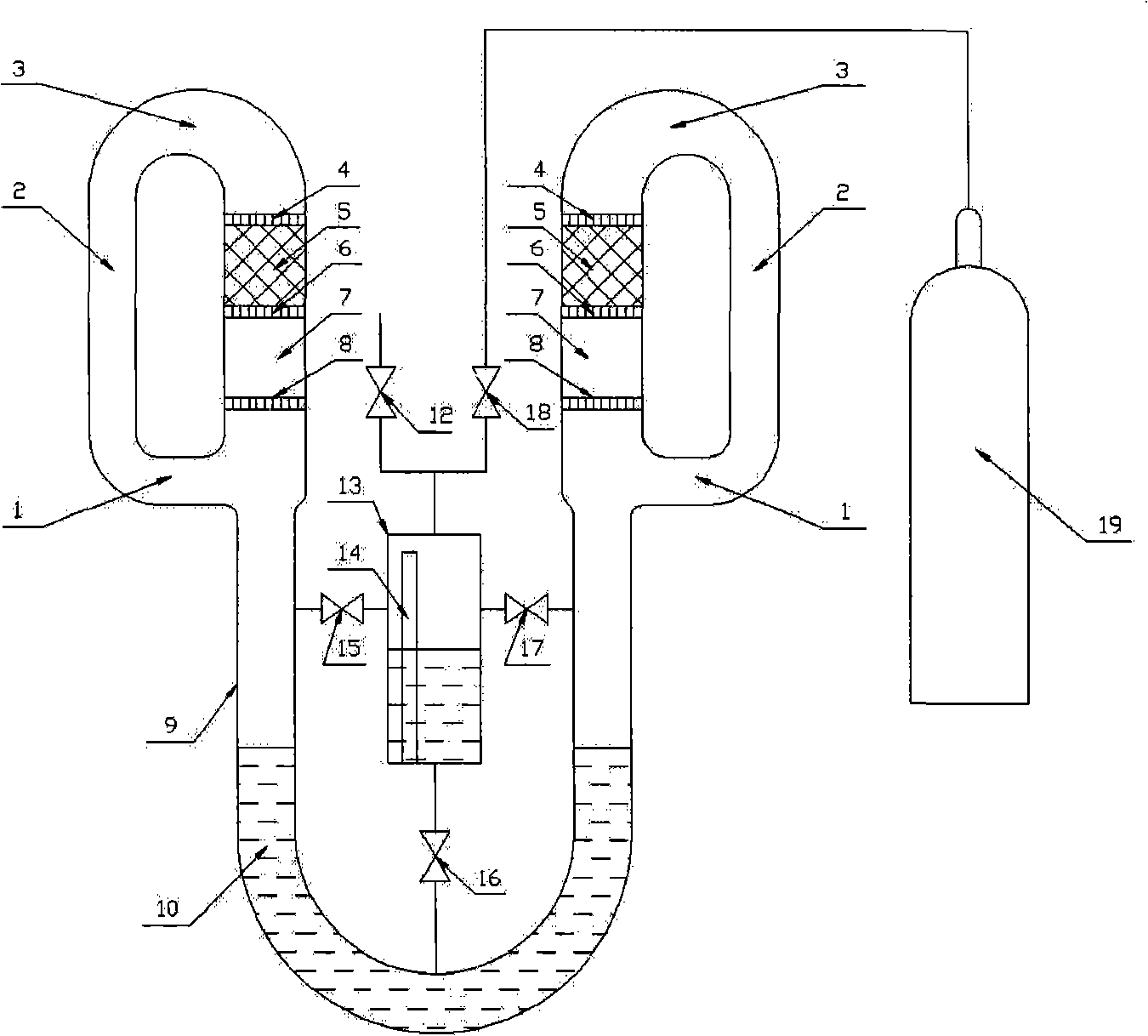

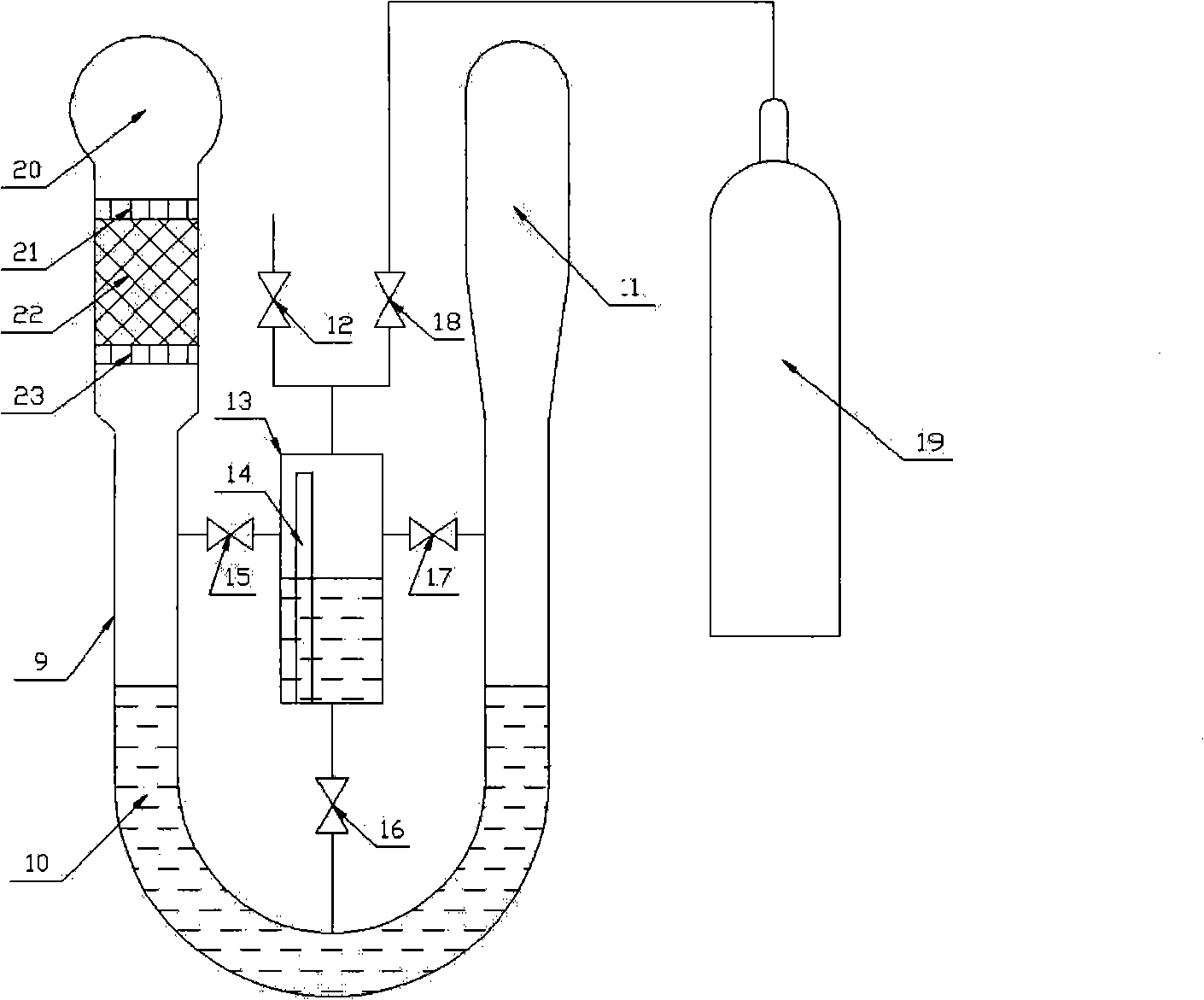

[0023] as attached figure 1 As shown, the gas-liquid two-phase working fluid coupling vibration thermoacoustic engine described in the present invention includes a loop traveling wave thermoacoustic core, a U-shaped resonant tube 9, a liquid piston 10, a resonant cavity 11 and an acoustic impedance connected in sequence. Regulator. The loop traveling wave thermoacoustic core includes a feedback tube 1, an acoustic sensing tube 2, an acoustic volume tube 3, a first water cooler 4, a regenerator 5, a heater 6, a thermal buffer tube 7 and a second water cooler connected in sequence 8. In the liquid piston 10, the room-temperature ionic liquid is placed in the U-shaped resonant tube 9 to form a liquid piston, thereby forming a gas-liquid coupling vibration together with the gas-phase working medium. The acoustic impedance regulator is characterized in that its main body is a gas-liquid balance tank 13, a liquid level gauge 14 is arranged inside it, and an exhaust valve 13 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com