Method for increasing light alloy micro-arc oxidation coat endurance life

A technology of micro-arc oxidation and fatigue life, applied in the direction of coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problem of reduced fatigue life of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

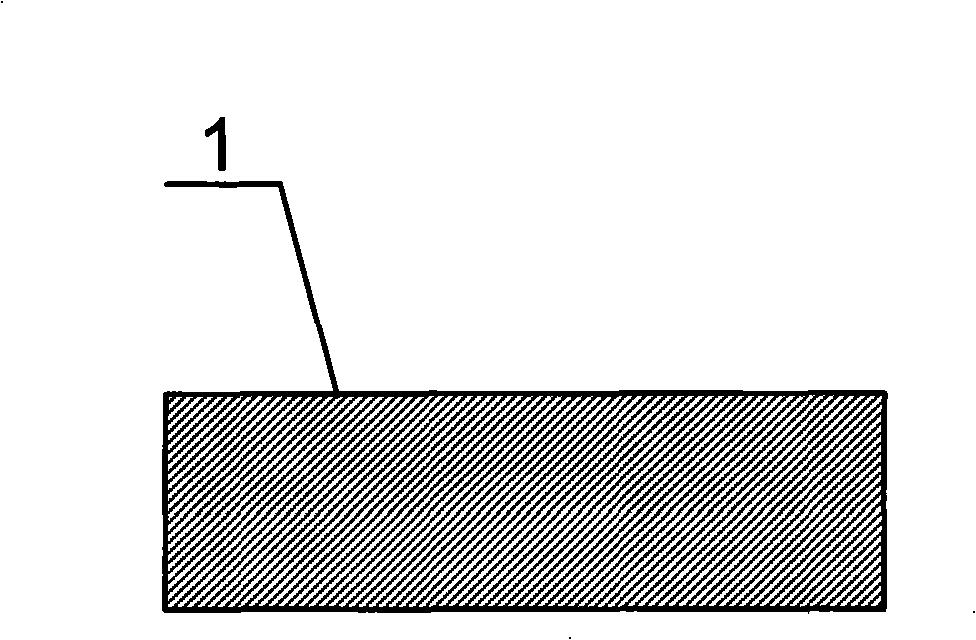

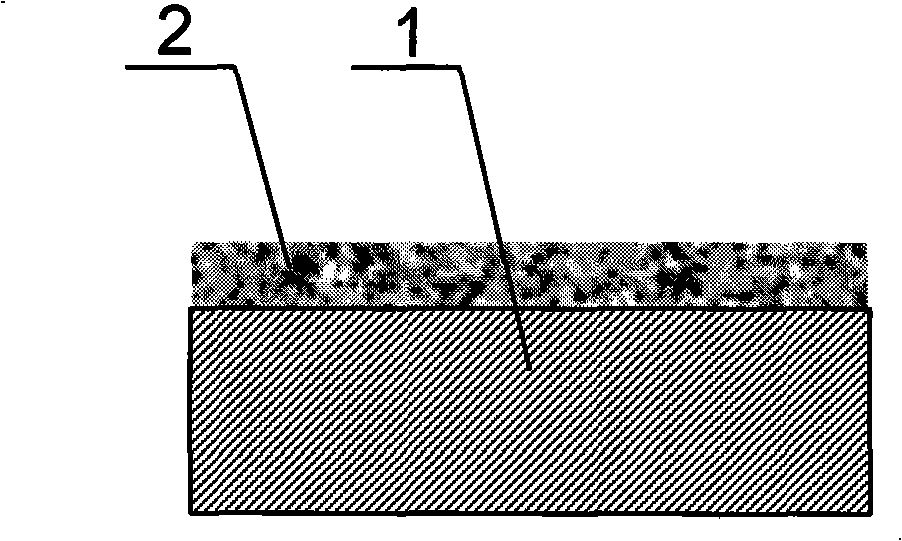

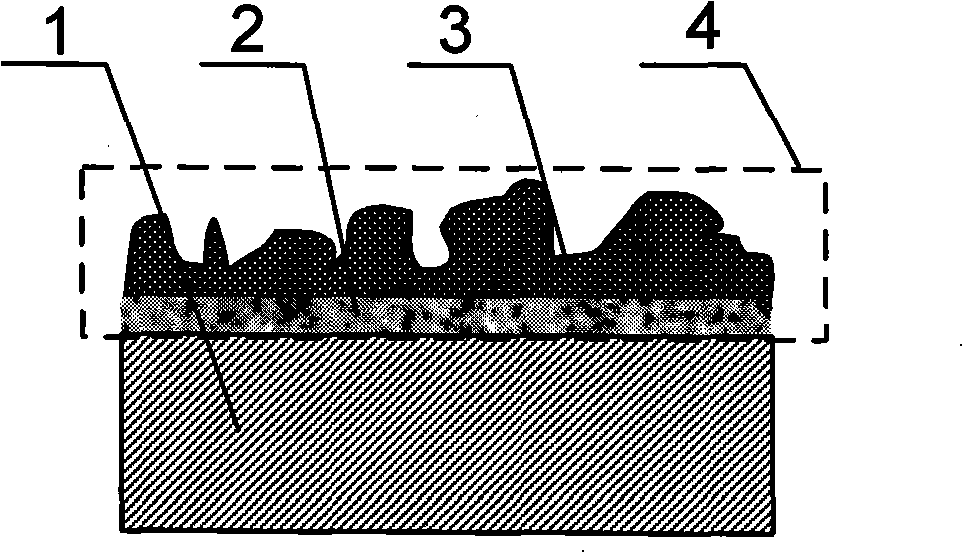

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, the steps of this embodiment are as follows:

[0014] Step 1: Substrate pretreatment: Light alloy metal surface 1 is polished and cleaned;

[0015] Step 2: surface nanocrystallization: a nanocrystalline layer 2 with a thickness of 10-20 μm is formed on the metal surface 1 of the light alloy by means of surface nanocrystallization;

[0016] Step 3: Micro-arc oxidation: place the light alloy after surface nanometerization in a stainless steel tank containing alkaline electrolyte, use the light alloy as the anode, and the stainless steel tank as the cathode; through the control of the electrical parameters of the micro-arc oxidation, The metal surface 1 of the light alloy forms a composite coating 4 of a nanocrystalline layer 2 and a micro-arc oxidation layer 3, and the thickness is controlled at 10-20 μm.

[0017] The aforementioned light alloys may be aluminum alloys, titanium alloys and magne...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the metal surface 1 is severely plastically deformed by using surface nanotechnology, resulting in a large number of dislocations, twins or sub-grain structures, resulting in the refinement of grains to the nanometer level The vibration frequency of the surface nanometerization is 48Hz, the spray distance is 30mm, the shot diameter is 3-10mm, and the shot blasting time is 15-60min, so as to obtain a nanocrystalline layer 2 with a thickness of 10-20μm; the surface nanometerization adopts high-energy spraying shot method, surface mechanical grinding method or supersonic spraying method. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the energy of the micro-arc oxidation process in step 3 is provided by an adjustable high-voltage and high-frequency bipolar pulse power supply, the pulse voltage is 400-600V, the frequency is 400-800Hz, The duty ratio is 4-20%, and the solution temperature is 0-50°C. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com