Method for preparing high storage stability room temperature dehydration sulfureted organic silicon coat

A storage stability, silicone technology, applied in chemical instruments and methods, anti-fouling/underwater coatings, coatings, etc., can solve problems such as long-term, unsatisfactory performance of silicone rubber, and decline in mechanical properties of products, and achieve the goal of using Convenience, improved storage stability, and easy-to-clean effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

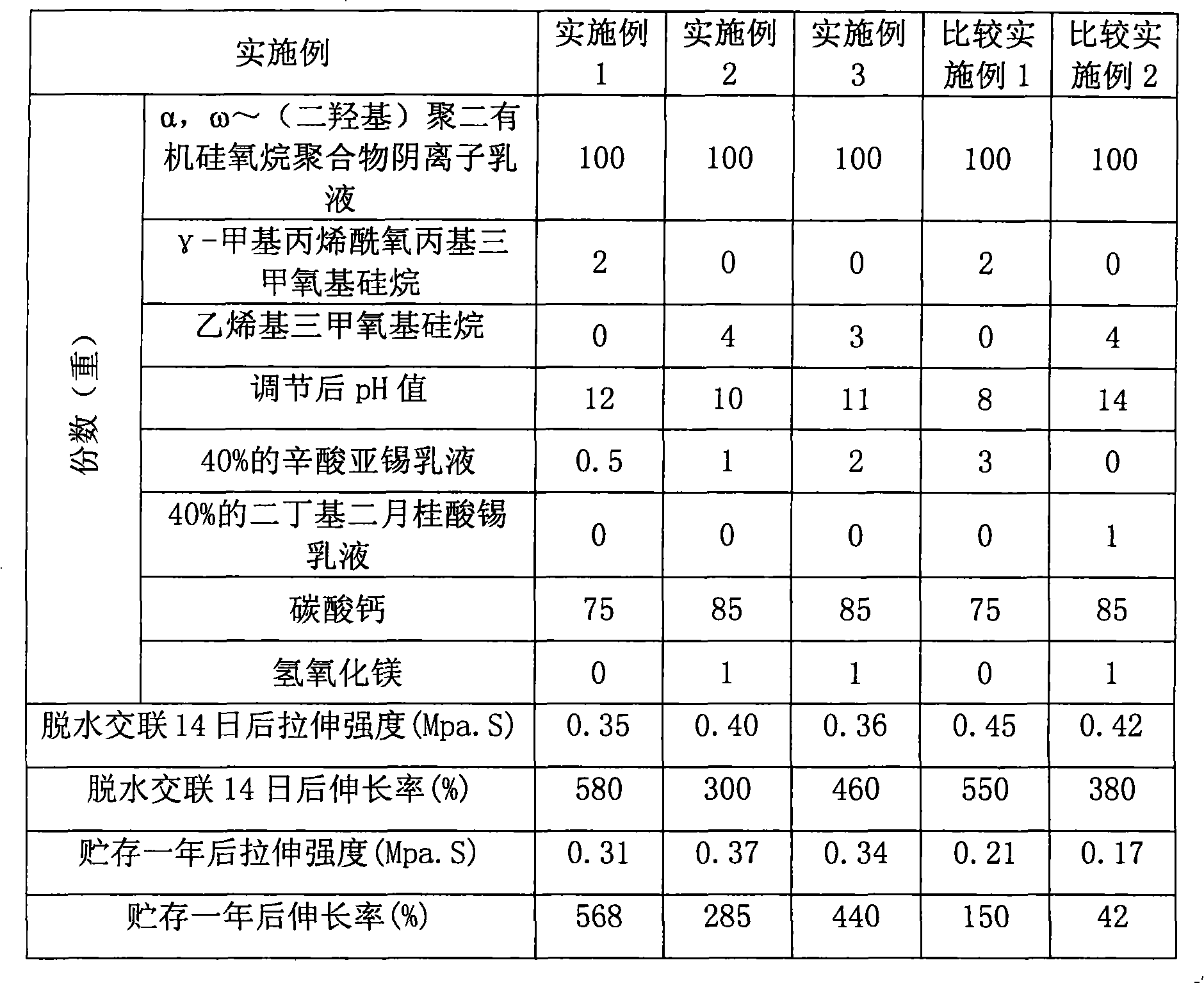

[0028] Add 100 parts of α, ω ~ (dihydroxy) polydiorganosiloxane polymer anionic emulsion, 2 parts of γ-methacryloxypropyl trimethoxysilane, and 0.5 parts of catalyst stannous octoate emulsion into the mixer and mix evenly , matured at room temperature for 1 day, adjusted the pH value of the above composition to 12 with ethylamine, added the above composition, 75 parts of inorganic filler calcium carbonate, 0.5 part of DSX3116 and 0.2 part of Foamaster-75 into a planetary mixer and stirred evenly to obtain a high storage capacity Stability room temperature dehydration vulcanization silicone coating, sample preparation according to the standard GB / T528-92, the mechanical properties were measured after 14 days, and the mechanical properties measured after the sample was stored for 12 months are shown in Table 1.

Embodiment 2

[0030] Add 100 parts of α, ω ~ (dihydroxy) polydiorganosiloxane polymer anionic emulsion, 4 parts of vinyltrimethoxysilane, and 1 part of catalyst stannous octoate emulsion into a mixer and mix evenly, and ripen at room temperature for 3 days. Ethylenediamine adjusted the pH value of the above composition to 10, and added the above composition together with 85 parts of calcium carbonate, 1 part of magnesium hydroxide, 0.5 part of DSX3116 and 0.2 part of Foamaster-75 into a planetary mixer and stirred evenly to obtain high storage stability The room temperature dehydration vulcanization silicone coating film was prepared according to the standard GB / T528-92. The mechanical properties were measured after 14 days, and the mechanical properties of the samples were measured after 12 months of storage. See Table 1 for details.

Embodiment 3

[0032] Add 100 parts of α, ω~(dihydroxy)polydiorganosiloxane polymer anionic emulsion, 3 parts of vinyltrimethoxysilane, 2 parts of catalyst stannous octoate emulsion into the mixer and mix evenly, ripen at room temperature for 3 days, use Ethylenediamine adjusted the pH value of the above composition to 11, and added the above composition together with 85 parts of calcium carbonate, 1 part of magnesium hydroxide, 0.5 part of DSX3116 and 0.2 part of Foamaster-75 into a planetary mixer and stirred evenly to obtain high storage stability The room temperature dehydration vulcanization silicone coating film was prepared according to the standard GB / T528-92. The mechanical properties were measured after 14 days, and the mechanical properties of the samples were measured after 12 months of storage. See Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com