Light diffusion film and surface light source using the same

A light-diffusing film and light-diffusing technology, which is applied in the field of side-lit surface light sources and directly below-type surface light sources, can solve the problems of reducing the intensity of light output, improving the luminance, reducing light transmittance, etc., and achieving clear viewing , easy-to-see effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

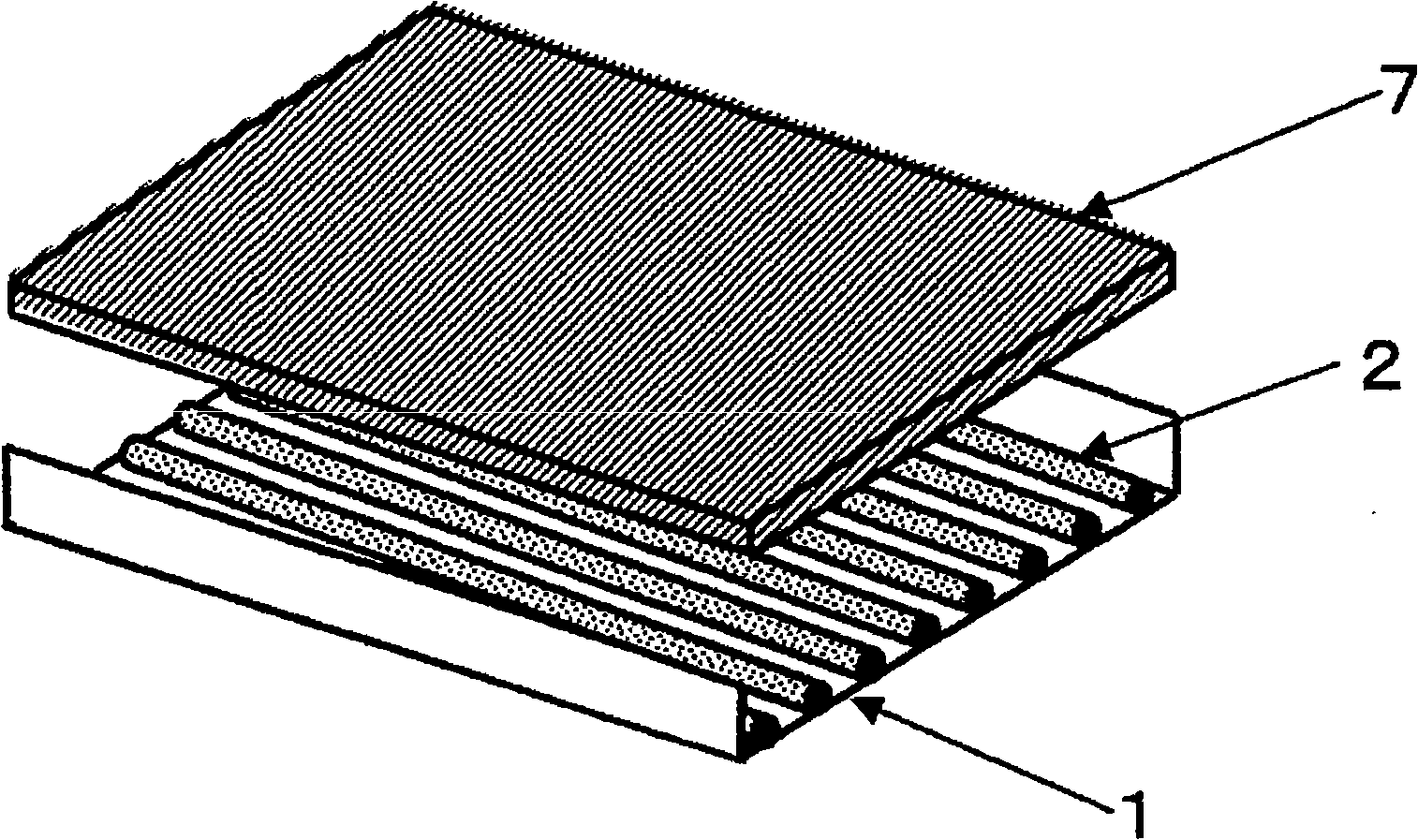

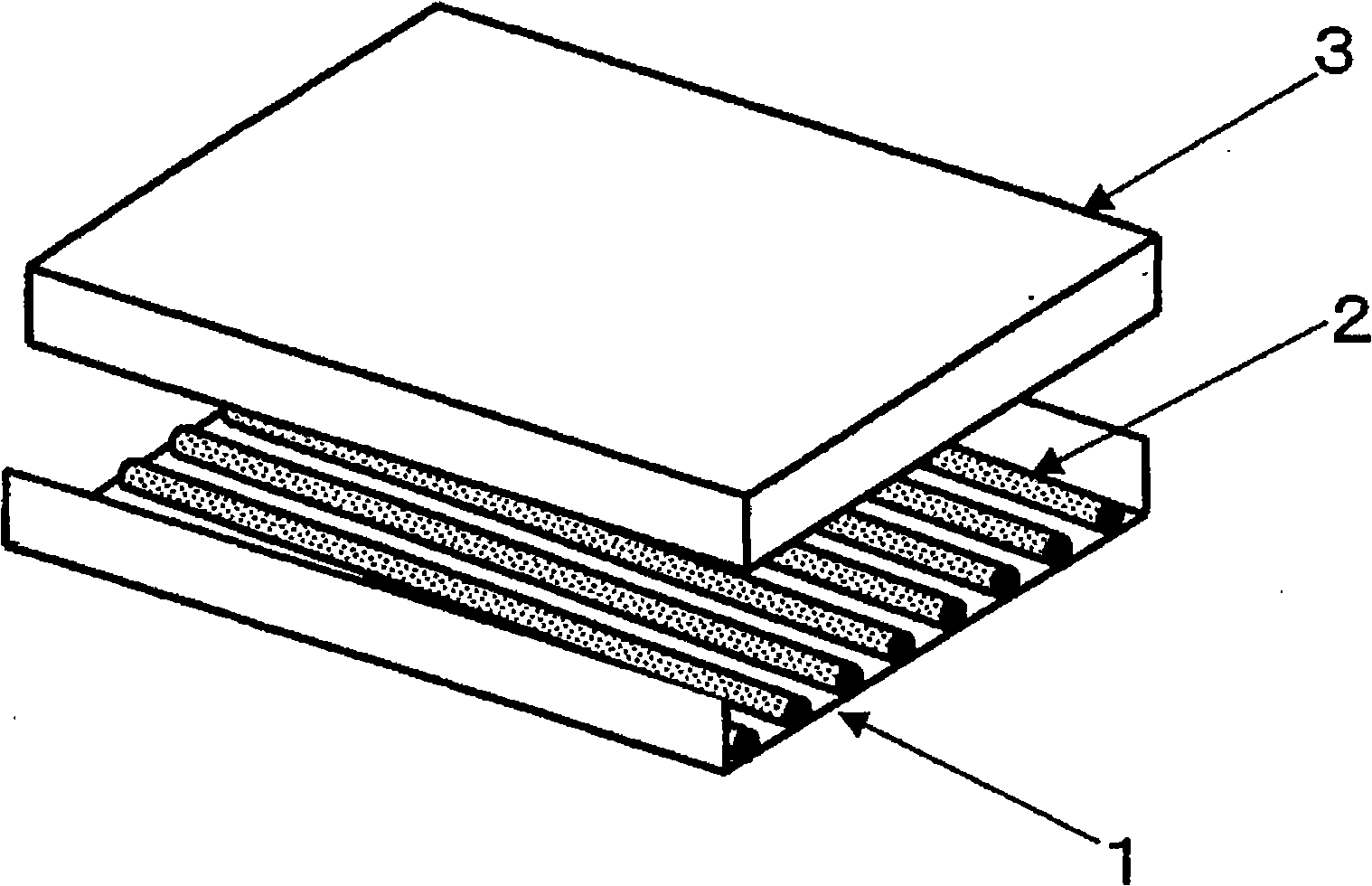

[0233] Supply to the extruder: with 99.93% by volume of polycarbonate as the main resin component constituting the light-diffusing film, with 0.07% by volume as the anatase type with an average particle diameter (diameter) of 1 micron as the light-diffusing element Titanium dioxide mixed balls. Next, melt extrusion was carried out, and a base material film was produced by cooling on a mirror-surfaced casting roll by an electrostatic application method.

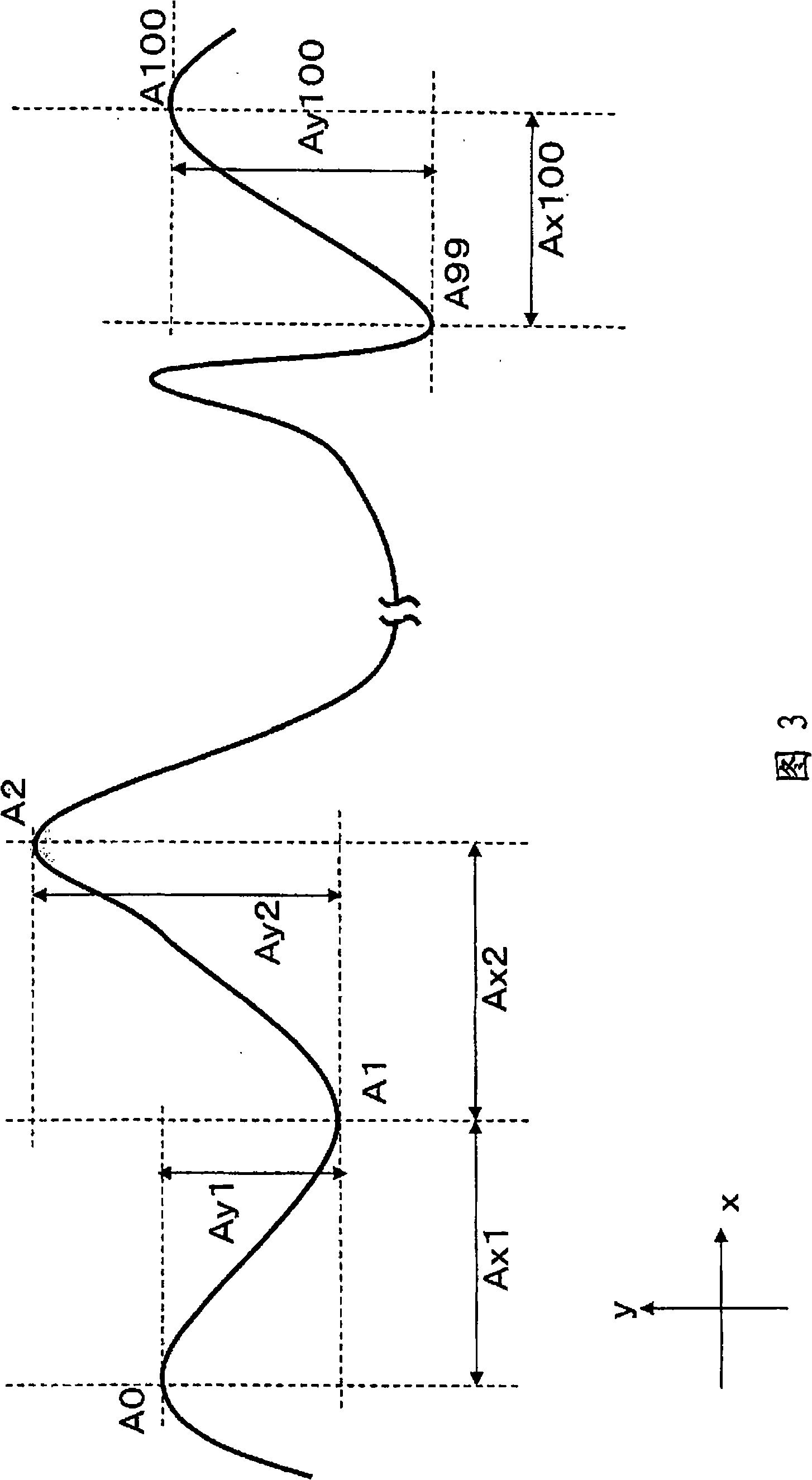

[0234] Concave-convex shapes were formed on one surface of this base material film by the method described below. In addition, the die used here is a die made of nickel on which a curved surface represented by the following formula has been formed.

[0235] z=5×sin(0.0691×x)+5×sin(0.0628×y)

[0236] Here, z is the mold thickness direction, and x, y are the mold surface directions. Also, the units are microns.

[0237] First, the obtained base material film and the mold were heated to 180° C. for 2 minutes. Next, the shape...

Embodiment 1-2

[0241] Supply to the extruder: as the main resin component constituting the light-diffusing film, the PET (hereinafter referred to as SPG-PET) formed by copolymerizing 30 mol of spiroglycol to ethylene glycol unit is 99.2 volume %, as light The polymethylpentene of the diffusing element was mixed at 0.8% by volume as pellets. Next, melt extrusion was carried out, and a base material film was produced by cooling on a mirror-surfaced casting roll by an electrostatic application method.

[0242] Concave-convex shapes were formed on one surface of the substrate film by the same method as in Example 1-1.

[0243] Maximum value Asmax, minimum value Asmin, anisotropy, number density, area occupancy, transmittance, and haze of light-diffusing elements in the film cross-section of the obtained light-diffusing film , total thickness, as shown in Table 1. In addition, the transmittance and the haze are numerical values measured by incident light from a surface formed with surface irr...

Embodiment 1-3

[0246] A pellet obtained by mixing 98.8% by volume of SPG-PET as a main resin component constituting the light-diffusing film and 1.2% by volume of polymethylpentene as a light-diffusing element was supplied to the extruder. Next, melt extrusion is carried out, and a base material film is produced by cooling on a mirror-surfaced casting roll by means of electrostatic application.

[0247] Concave-convex shapes were formed on one surface of the substrate film by the same method as in Example 1-1.

[0248] Maximum value Asmax, minimum value Asmin, anisotropy, number density, area occupancy, transmittance, and haze of light-diffusing elements in the film cross-section of the obtained light-diffusing film , total thickness, as shown in Table 1. In addition, the transmittance and the haze are numerical values measured by incident light from a surface formed with surface irregularities. In addition, polymethylpentene was spherically dispersed as a result of cross-sectional obser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com