Expansion wave firearm

An expansion wave and gun technology, applied in the field of expansion wave guns, can solve the problems of greatly increased structural weight, inability to use metal cartridges, and inability to adapt to gun tail flames, so as to speed up the research and development speed and reduce the difficulty and risk of research and development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

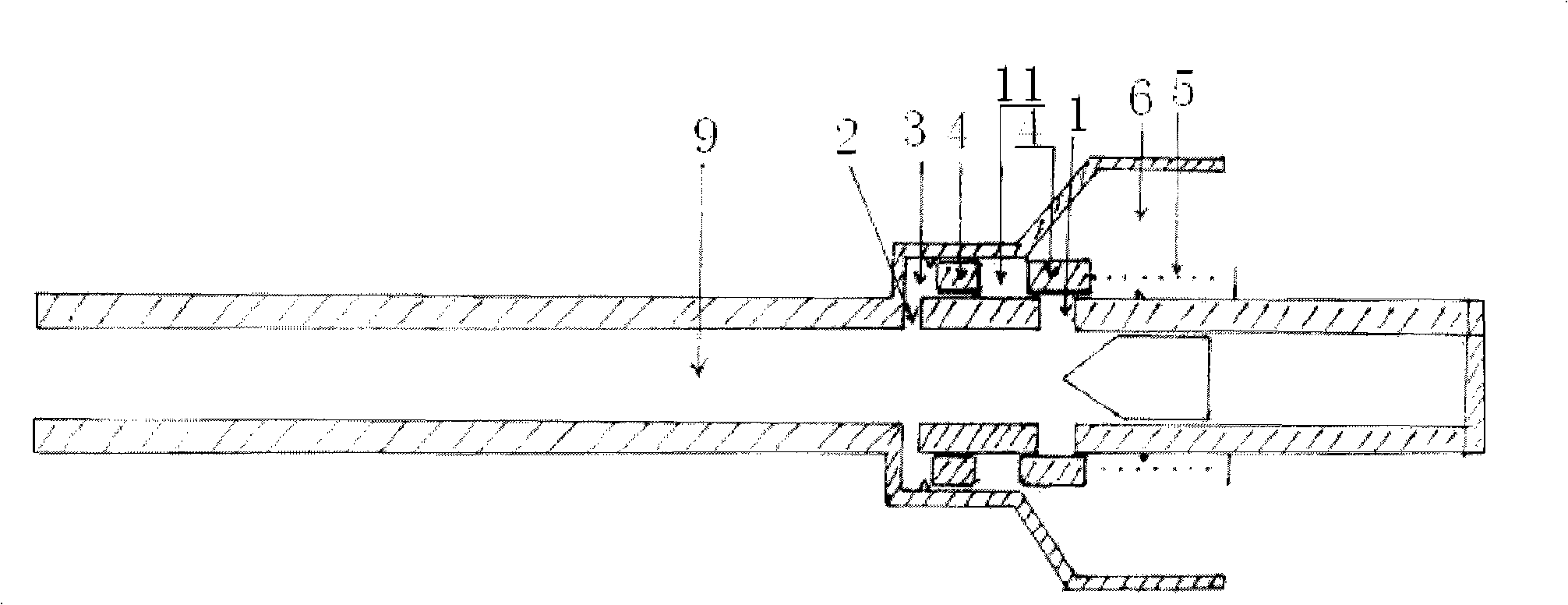

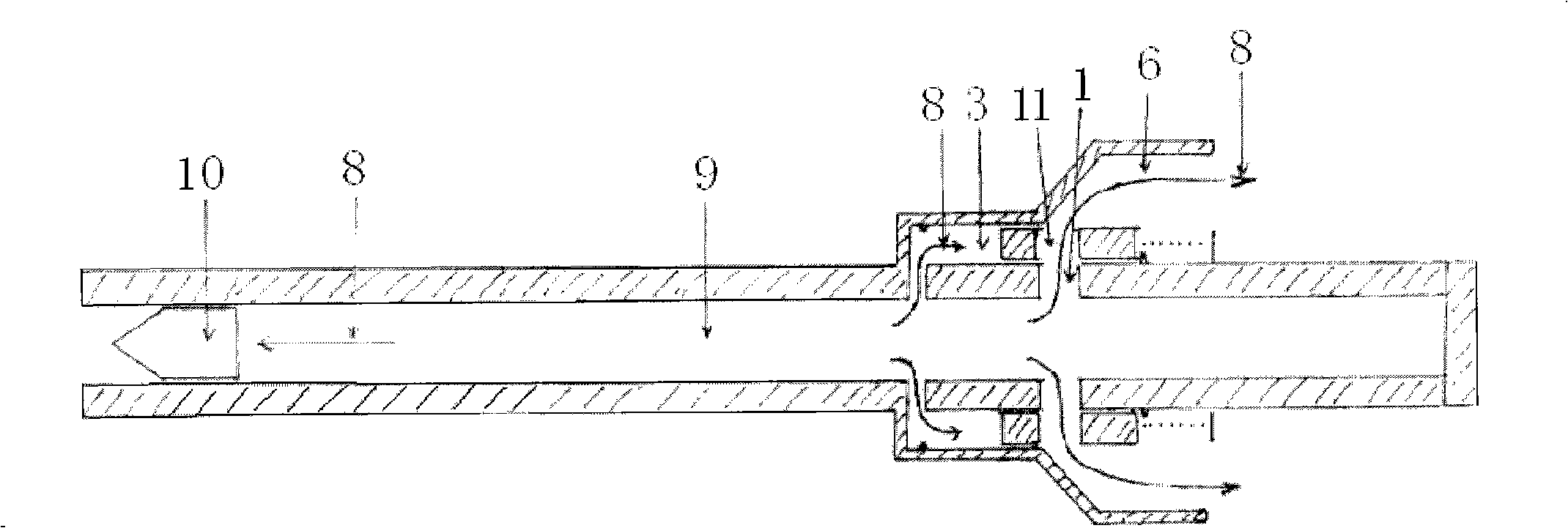

[0024] Embodiment 1: expansion wave large-caliber anti-equipment sniper rifle (12.7~25 millimeters of caliber, such as Figure three ).

[0025] Its profile of the large-caliber anti-equipment sniper rifle (can be 12.7~25 millimeters of caliber) designed on the basis of the present invention is as follows: Figure three , its launch method is similar to the shoulder-fired rocket launcher and the M82A2 12.7mm large-caliber anti-material sniper rifle designed by the American Barrett company to deal with helicopters on the battlefield. It is a bullpup gun structure with a small grip in front of the handguard. , usually equipped with a light dot sight to capture moving targets, it can be carried on the shoulder for unsupported shooting, the shoulder support is moved forward to about the rear 1 / 3 of the weapon's full length, and the gas is pushed toward the weapon during the internal trajectory when shooting. Push the piston 4 back to make the propellant gas spray backward from th...

Embodiment 2

[0035] Embodiment 2: expansion wave autocannon (as 12.7~37 millimeters of caliber).

[0036] Applying the present invention to machine guns to produce expansion-wave machine guns, coupled with high-efficiency muzzle brakes, can reduce the recoil force by about 90%, and reduce its weight, so that the recoil force of the machine guns is pushed in the opposite direction by its shooting Most of the reaction force formed by the gas is offset, so that the adverse effect of the recoil on the flight of the helicopter is greatly reduced. At the same time, it is possible for the helicopter of the same type to mount a larger caliber cannon (such as 35 to 37 mm or a larger caliber) to improve Range and striking power.

[0037] Because of the expansion wave gun of the present invention, the structure of its excretion propellant gas is all on the barrel tube wall, and the structure of the controllable backward discharge of the propellant gas by the barrel tube wall near the front end of the...

Embodiment 3

[0039] Embodiment 3: Expansion wave is big, medium-caliber self-propelled artillery.

[0040] Because the expansion wave gun of the present invention adopts the structure that the flame vent hole on the body tube sprays propellant gas backward through the expanded nozzle to offset most of the recoil force, without the need to inject propellant gas through the inertial recoil of the gun tail, the launch The breech of the gun was always locked during the process. So the expansion wave gun of the present invention can also be applied to the traditional self-propelled artillery (as Figure four ), such as the PLZ05 155 mm 52-caliber barrel howitzer, if the flame vent and the propellant gas nozzle are designed at the barrel of 39 to 45 times the caliber, and there is no need to install a flame vent opening control device such as a piston, the vent The flame hole directly sprays the propellant gas backward through the expanded nozzle to offset most of the recoil force. Since it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com