Antistatic thermo-shrinkage material and manufacturing method thereof

A manufacturing method and anti-static technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy falling off of anti-static film, easy falling off of anti-static coating, anti-static effect, etc., to prevent the generation and accumulation of static electricity , the effect of small resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take polyolefin resin and adopt polyethylene (PE), 100 parts; Carbon black, 12 parts; Antioxidant tetrakis [β-(3', 5'-di-tert-butyl-4'-hydroxyphenyl) propionic acid] Pentaerythritol ester (commonly known as: 1010), 1 part; plastic processing lubricant adopts zinc stearate, 1.5 parts;

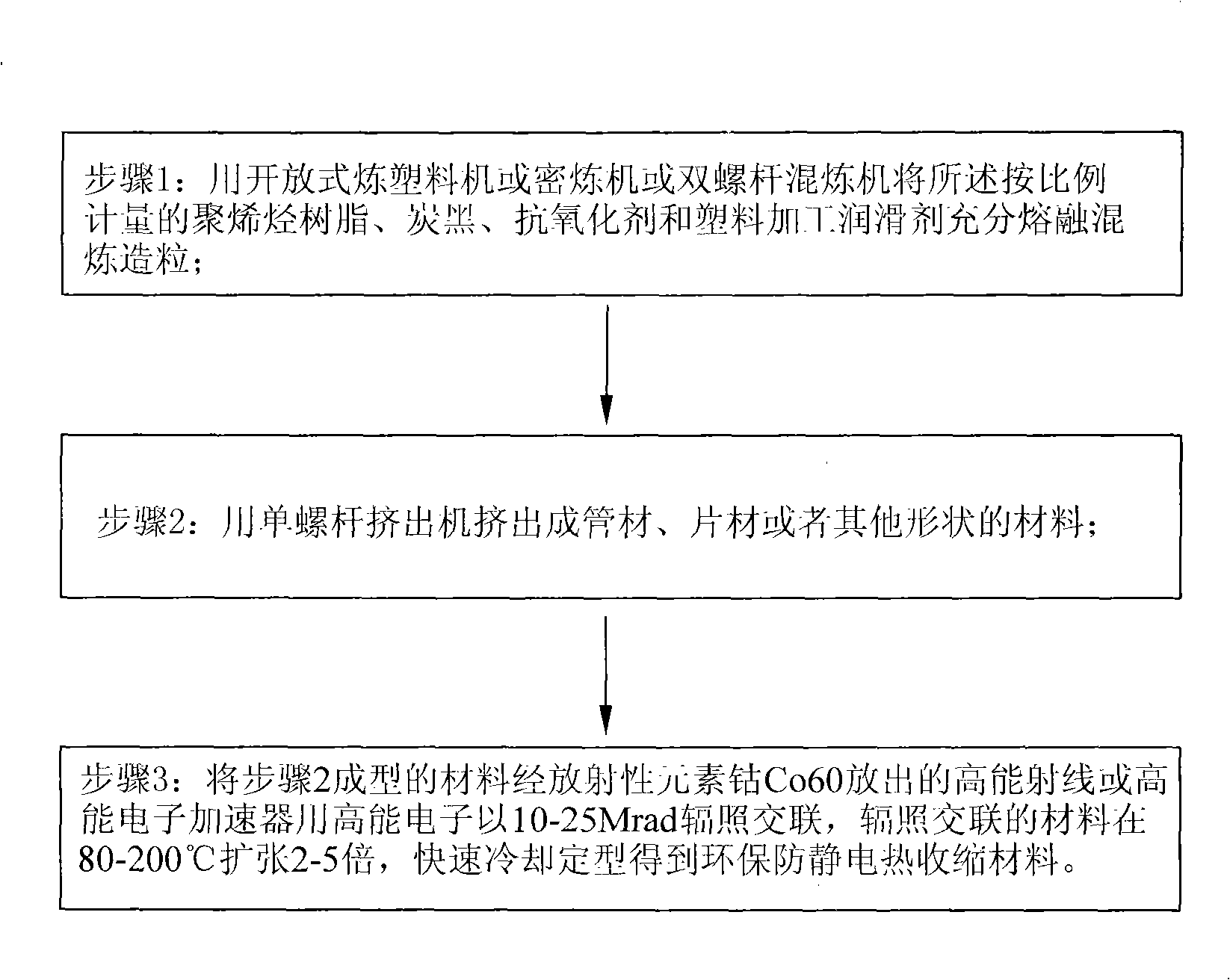

[0028] Fully melt, knead and granulate the polyolefin resin, carbon black, antioxidant and plastic processing lubricant measured in proportion with an open plastic mill or internal mixer or twin-screw mixer;

[0029] Extrude the uniformly mixed masterbatch into a pipe with a certain inner diameter and wall thickness with a conventional plastic single-screw extruder, and use a high-energy electron accelerator or radioactive element cobalt Co 60 After a certain dose of high-energy radiation is irradiated (about 10Mrad or 100KGY), the tube is first heated to 150°C, and the internal diameter of the tube is increased to 2.5 times the original by using the internal and external pressure differe...

Embodiment 2

[0031] Take ethylene-vinyl acetate copolymer EVA (VA content 14-18%) 80 parts, ethylene propylene rubber 20 parts; carbon black, 20 parts; antioxidant tetrakis [β-(3', 5'-di-tert-butyl -4'-hydroxyphenyl) propionic acid] pentaerythritol ester (commonly known as: 1010), 0.3 part; plastic processing lubricant adopts zinc stearate, 0.5 part;

[0032] Fully melt, knead and granulate the polyolefin resin, carbon black, antioxidant and plastic processing lubricant measured in proportion with an open plastic mill or internal mixer or twin-screw mixer;

[0033] Extrude the uniformly mixed masterbatch into a sheet with a certain width and thickness with a conventional plastic single-screw extruder, and use a high-energy electron accelerator or radioactive element cobalt Co 60 After irradiating a certain dose of high-energy radiation (about 10Mrad or 100KGY), the sheet is first heated to 150°C, and the sheet is stretched to both sides by mechanical force to make its width and inner diame...

Embodiment 3

[0035] Take 80 parts of ethylene-vinyl acetate copolymer EVA (VA content 14-18%), 20 parts of ethylene-propylene rubber; carbon black, 12.5 parts; antioxidant tetrakis[β-(3',5'-di-tert-butyl -4'-hydroxyphenyl) propionic acid] pentaerythritol ester (commonly known as: 1010), 0.5 part; plastic processing lubricant adopts zinc stearate, 1 part;

[0036] Fully melt, knead and granulate the polyolefin resin, carbon black, antioxidant and plastic processing lubricant measured in proportion with an open plastic mill or internal mixer or twin-screw mixer;

[0037] The uniformly mixed masterbatch is extruded into a sheet with a certain width and thickness with a conventional plastic single-screw extruder, and is processed by a high-energy electron accelerator or radioactive element cobalt Co 60 After irradiating a certain dose of high-energy radiation (about 10Mrad or 100KGY), the sheet is first heated to 150°C, and the sheet is stretched to both sides by mechanical force to make its w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com