Sintering device flue gas multiple pollutant removing process and system thereof

A sintering machine and pollutant technology, which is applied in the directions of air quality improvement, electrostatic effect separation, dispersed particle filtration, etc., can solve the problems of unsatisfactory sintering flue gas purification treatment effect, low nitrogen oxide removal efficiency, and high equipment anti-corrosion requirements. , to achieve the effect of saving initial investment and operating costs of equipment, reducing flue gas flow resistance, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

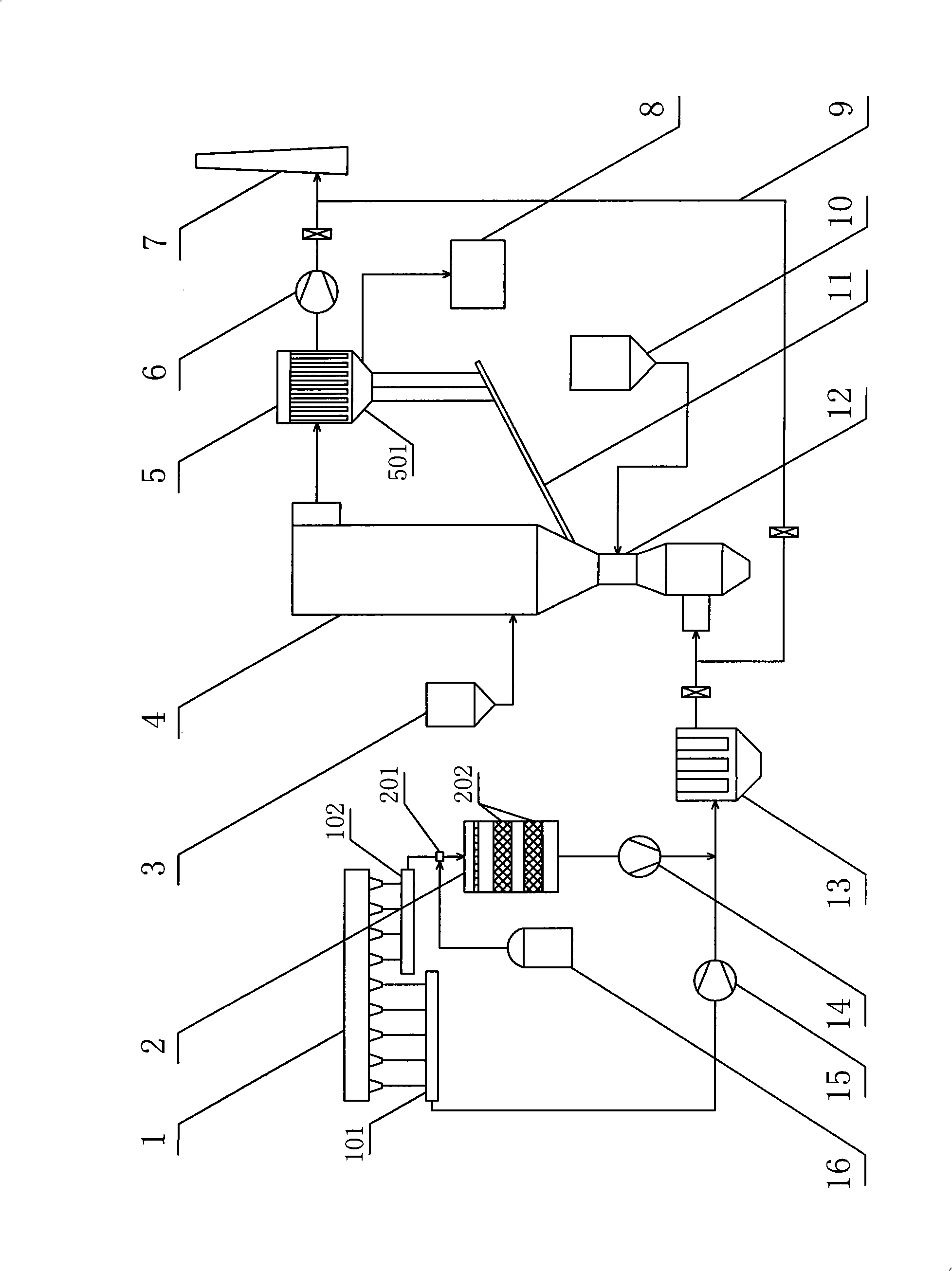

[0027] Below for the discharged flue gas of a sintering machine, the present invention will be further described in detail in conjunction with the accompanying drawings:

[0028] The sintering machine flue gas multi-pollutant removal system shown in the figure is mainly composed of a head flue gas header 101 and a tail flue gas header 102 for collecting flue gas at both ends of the sintering machine 1, and a flue gas header 102 for flue It is composed of SCR denitrification reactor 2, primary dust collector 13, circulating fluidized bed desulfurization reactor 4 and secondary dust collector 5 for removing various pollutants in the gas. The SCR denitrification reactor 2 includes an ammonia injection device 201 arranged outside the reactor and an SCR catalyst layer 202 arranged inside the reactor. The ammonia injection device 201 is connected to the ammonia storage tank 16, and the SCR catalyst layer 202 adopts a honeycomb or plate structure. The primary dust collector 13 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com