Method for cleaning polycrystalline silicon gate surface

A polysilicon gate, surface deposition technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems affecting device yield and other issues, and achieve the effect of improving yield, reducing defects, and improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the method for cleaning the surface of the polysilicon gate of the present invention are described below in order to further understand the purpose, specific structural features and advantages of the present invention.

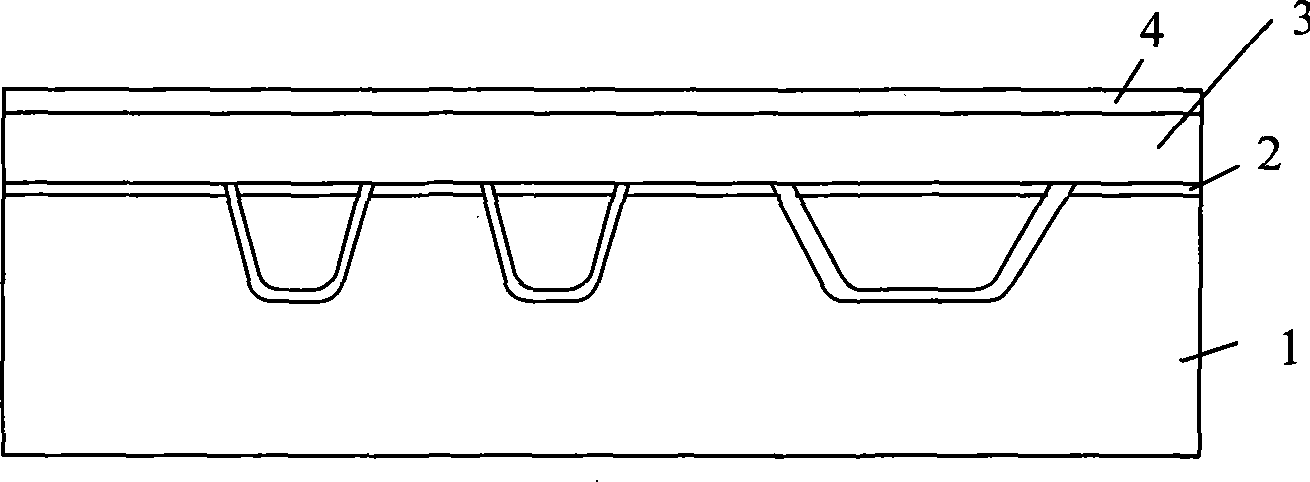

[0009] figure 1 It is a partial cross-sectional structure diagram of a silicon wafer for making a MOS device. The silicon wafer includes a substrate 1 , a gate oxide layer 2 and a polysilicon gate 3 formed on the substrate 1 . In order to improve the conductivity of the polysilicon gate 3 , it is necessary to deposit a tungsten silicide layer 4 on the surface of the polysilicon gate 3 . In order to improve the adhesion performance between the polysilicon gate 3 and the tungsten silicide layer 4 , before depositing the tungsten silicide layer 4 , it is necessary to perform the cleaning method provided by the present invention on the surface of the polysilicon gate 3 .

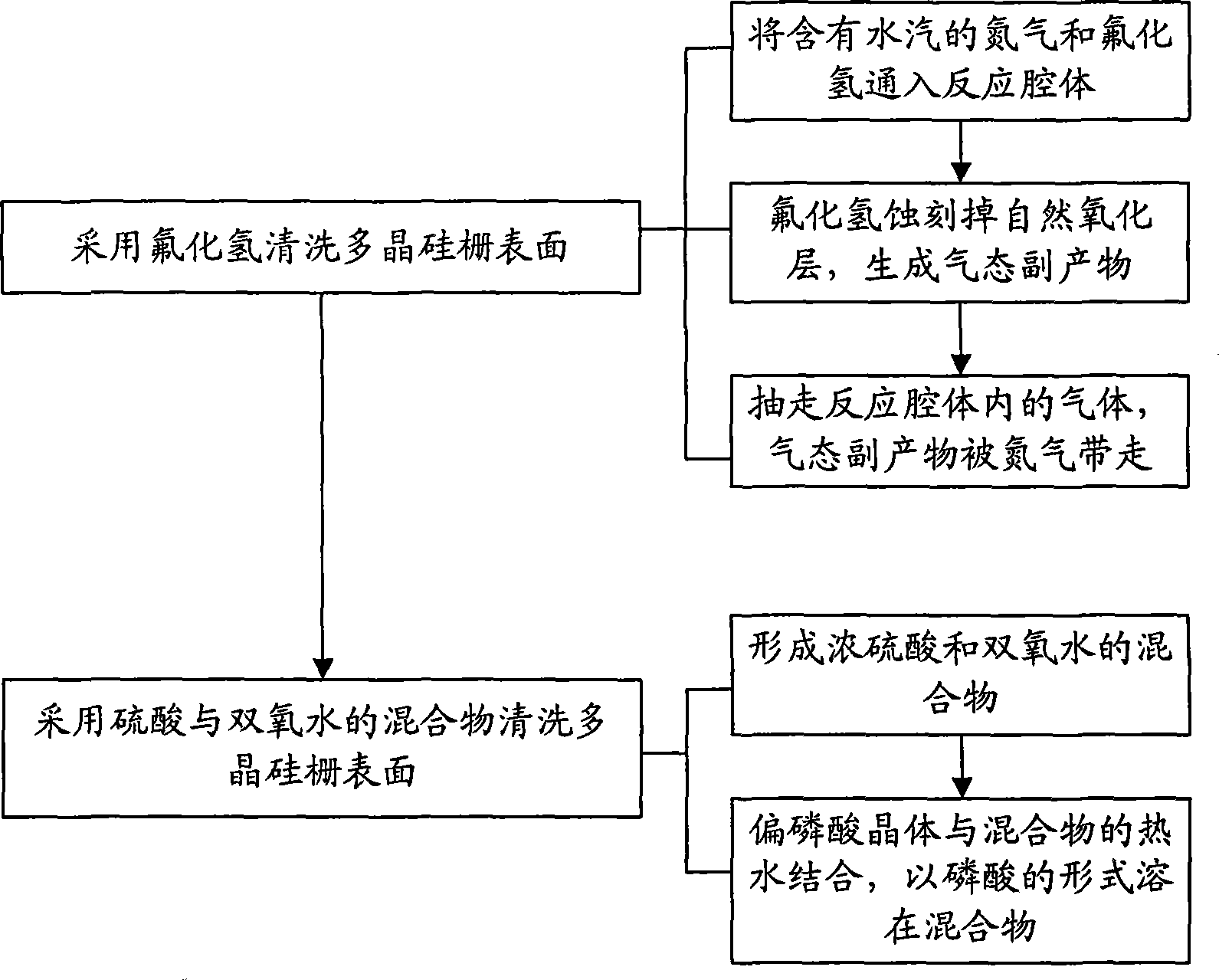

[0010] see figure 2 combine figure 1 The cleaning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com