Microwave method for synthesizing nickel phosphates cobalt microporous material

A technology of microwave synthesis and nickel-cobalt phosphate, which is applied in the field of molecular sieve materials, can solve the problems of long synthesis time, uneven heating, and uneven particle size of the product, so as to reduce the grain size, improve the catalytic performance, and improve the particle size. evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

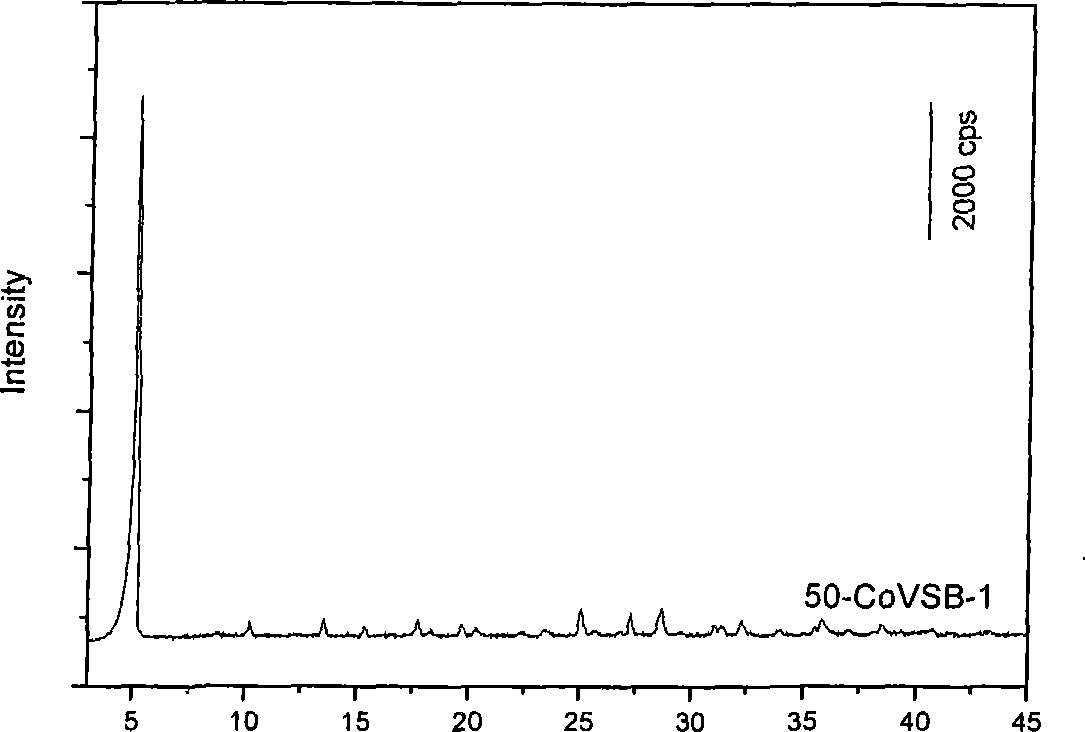

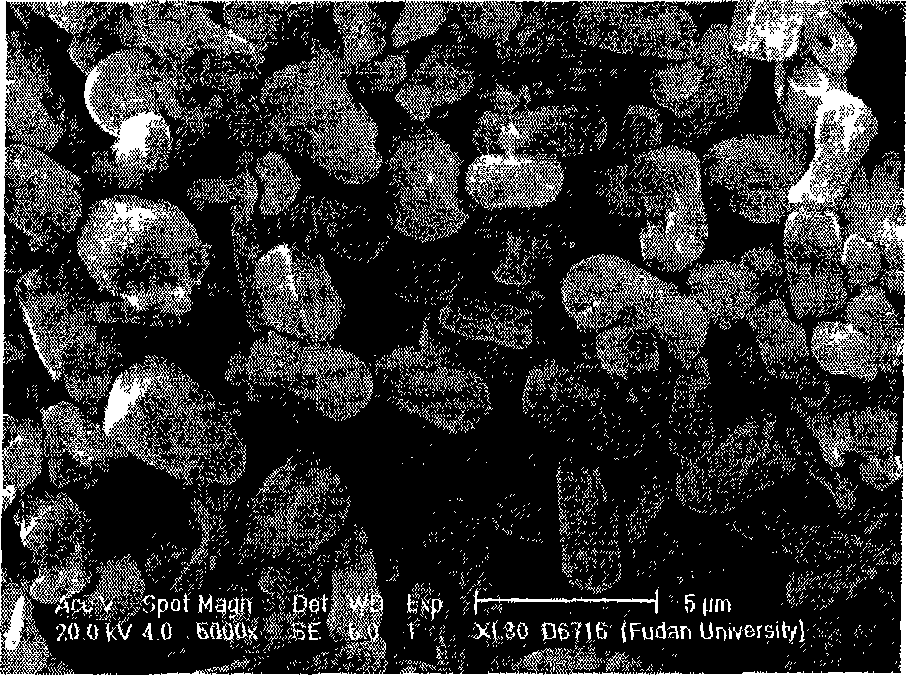

[0015] Example 1: Weigh 2.31g of nickel chloride and 2.30g of cobalt chloride and dissolve them in 14mL of distilled water, add 2.24mL of orthophosphoric acid dropwise while stirring; then, add 0.97mL of hydrofluoric acid; finally add 1.18mL of ethylenediamine Template agent, after stirring for 30 minutes to mix evenly, move the mixed material into a digestion tank, and synthesize under microwave irradiation conditions. The heating mode of the microwave oven adopts the temperature control mode, set the crystallization temperature to 180°C, first use 1000W power to heat for 1 minute, and the temperature is displayed as 95°C; then use 400W power to continue heating for 2 minutes, and then the temperature rises to 180°C Keep it for 27min. After the temperature of the digestion tank dropped to room temperature, the obtained solid product was centrifuged and washed 3 times with deionized water, and freeze-dried to obtain the original powder. XRD analysis see figure 1 . The main c...

Embodiment 2

[0016] Embodiment 2: In embodiment 1, the proportion of reactants remains unchanged, and the order of addition remains unchanged. After the reactants are uniformly mixed, they are transferred into a digestion tank and synthesized under microwave irradiation conditions. The heating mode of the microwave oven adopts the temperature control mode, and the crystallization temperature is set to 130°C. First, use 1000W power to heat for 1 minute, and the temperature is displayed as 75°C; then use 400W power to continue heating for 3 minutes, and the temperature rises to 130°C. Keep for 26min. After the temperature of the digestion tank dropped to room temperature, the solid product was centrifuged and washed 3 times with deionized water, and the sample of Example 1 could still be obtained after freeze-drying.

Embodiment 3

[0017] Embodiment 3: In embodiment 1, the proportion of reactants remains unchanged, and the order of addition remains unchanged. After the reactants are uniformly mixed, they are transferred into a digestion tank and synthesized under microwave irradiation conditions. The heating mode of the microwave oven adopts the temperature control mode, set the crystallization temperature to 180°C, first use 1000W power to heat for 1 minute, and the temperature is displayed as 95°C; then use 400W power to continue heating for 2 minutes, and then the temperature rises to 180°C Keep for 12min. After the temperature of the digestion tank dropped to room temperature, the solid product was centrifuged and washed 3 times with deionized water, and the sample of Example 1 could still be obtained after freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com