Nylon belt ink dyeing method for stylus printer

A needle-type printer and nylon belt technology, applied in printing, ink ribbon, ink and other directions, can solve the problem of low ink capacity per unit ribbon, achieve slow color decay speed, enhanced molecular activity, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

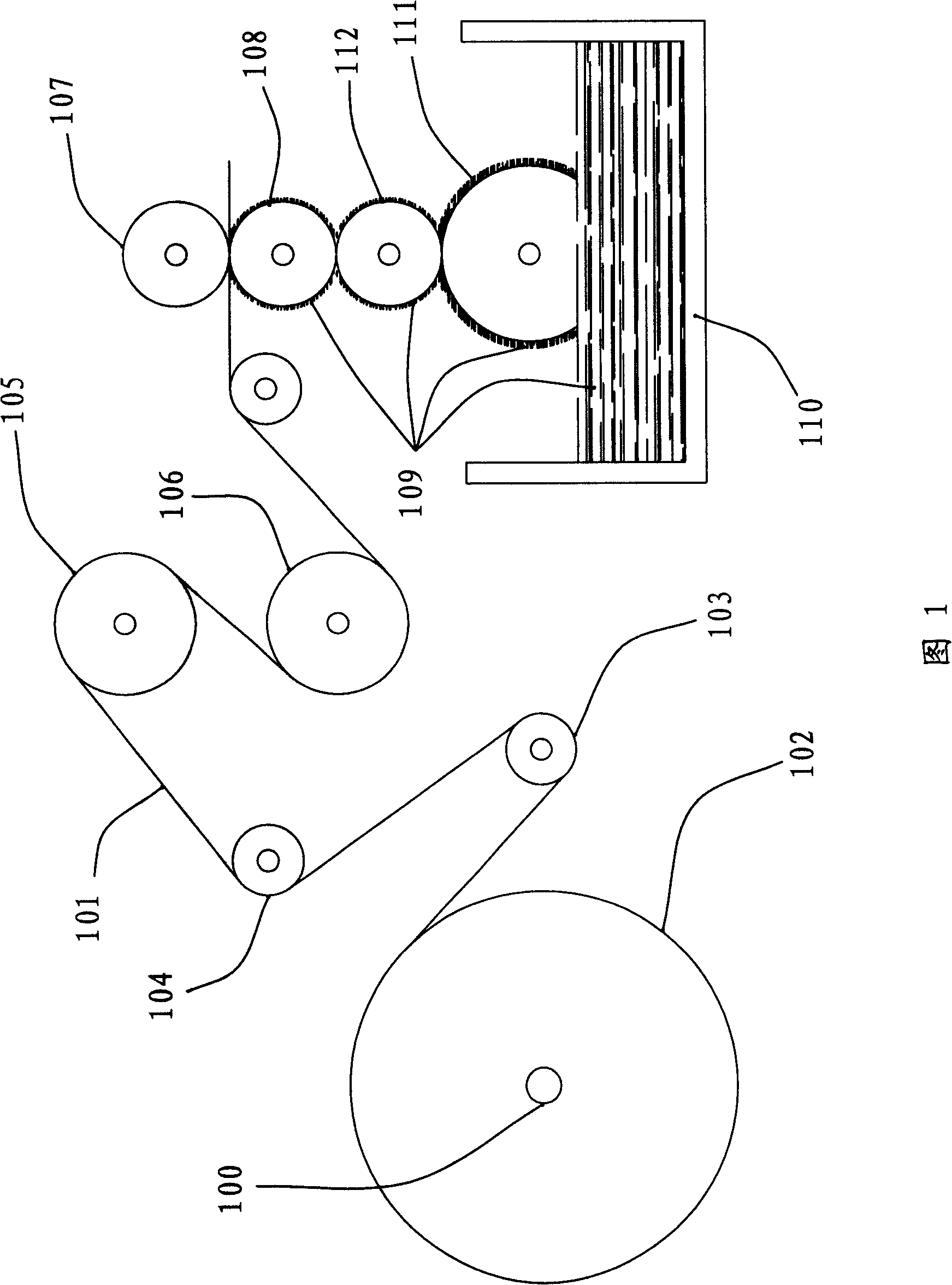

[0016] Below in conjunction with accompanying drawing 1, describe in detail the specific implementation process of the nylon tape dyeing ink method of the dot matrix printer of the present invention.

[0017] The main component of the blank nylon belt used in the experiment is PA66. According to the records on page 60 of the "Engineering Plastics Handbook" first published by Machinery Industry Press in October 2004, PA66 is a semi-crystalline polymer material with a relatively high melting point. As long as it is lower than its melting temperature, it It can maintain sufficient rigidity. Compared with ordinary thermoplastic resins, it has a higher service temperature, higher toughness, and excellent heat resistance, but it has high water absorption. The moisture absorption of pure PA66 reaches 8.5% in saturated state. Equilibrium moisture absorption at 5% RH is 2.5%.

[0018] The black ink is used in the experiment, and its components are pigments such as carbon black, anil...

Embodiment 2

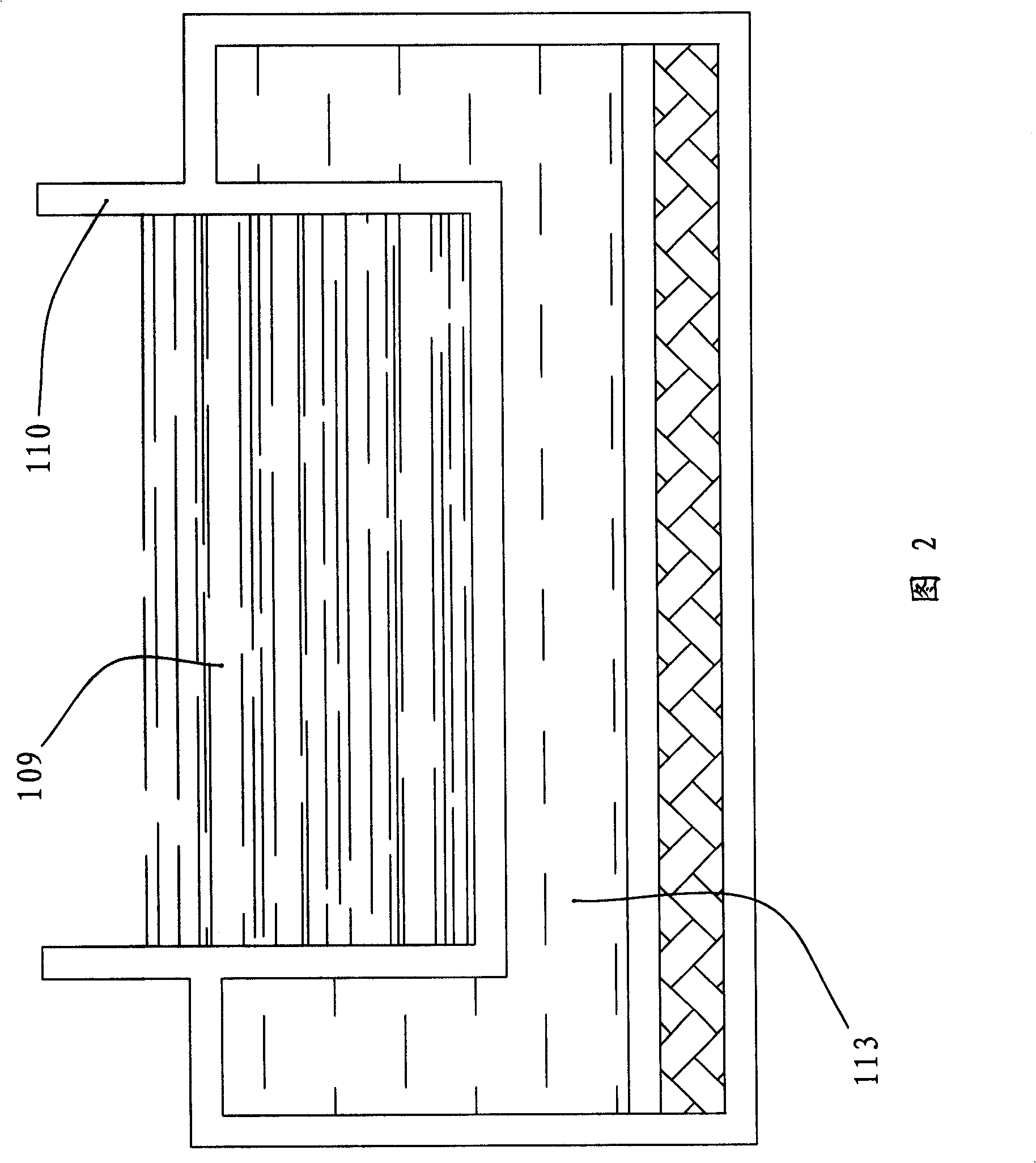

[0022] As shown in Figure 2, this embodiment adds a process step on the basis of Embodiment 1, which is to carry the surface of the printing and dyeing roller 108 before the blank nylon belt 101 passes through the gap between the two printing and dyeing rollers 107 and 108. The temperature of the ink 109 is raised to 30°C to 60°C. When specifically heating up, the ink tank 110 that is filled with ink 109 is floated in the tank 113 that has a certain amount of tap water, and the ink 109 is heated to a predetermined value by means of water bath heating, so that the ink 109 passes through the ink delivery roller 111 and the transfer roller 112 After the two-stage transmission reaches the printing and dyeing roller 108, it still has a temperature of 30°C to 60°C.

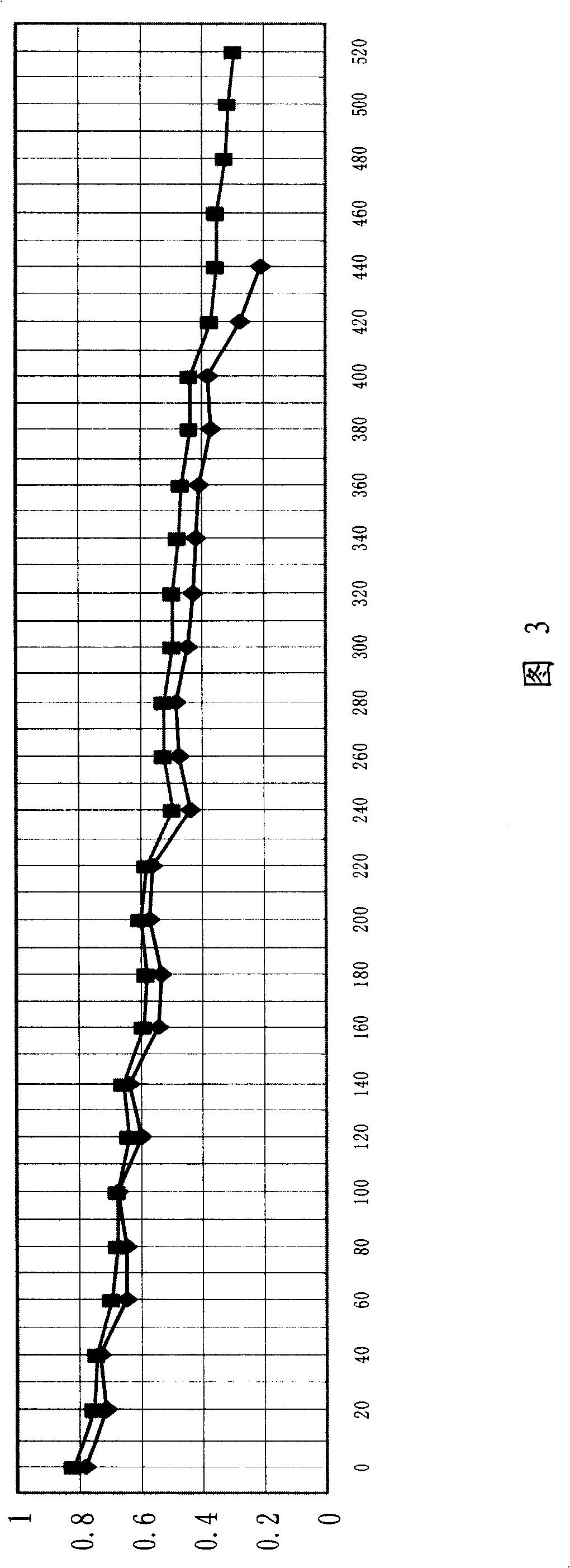

[0023] As shown in Figure 3 (the ordinate in the figure represents the reflectivity of printed writing. The reflectivity refers to the ratio of the reflectivity of an object to light to the reflectivity of a standard sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com