Transparent conductive polymer as amorphous silicon battery p layer

A technology for hydrogenating amorphous silicon and transparent metals, applied in the field of solar energy materials, can solve the problems of reducing photocurrent collection efficiency, increasing p-layer resistance, and increasing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A representative method for forming conductive polymers is to use vacuum coating to produce p-type conductive polymers with a thickness in the range of 10-30 nanometers at a temperature not exceeding 300 ° C, including nitrogen-sulfur long Polymers composed of chain polymers and hydrocarbons.

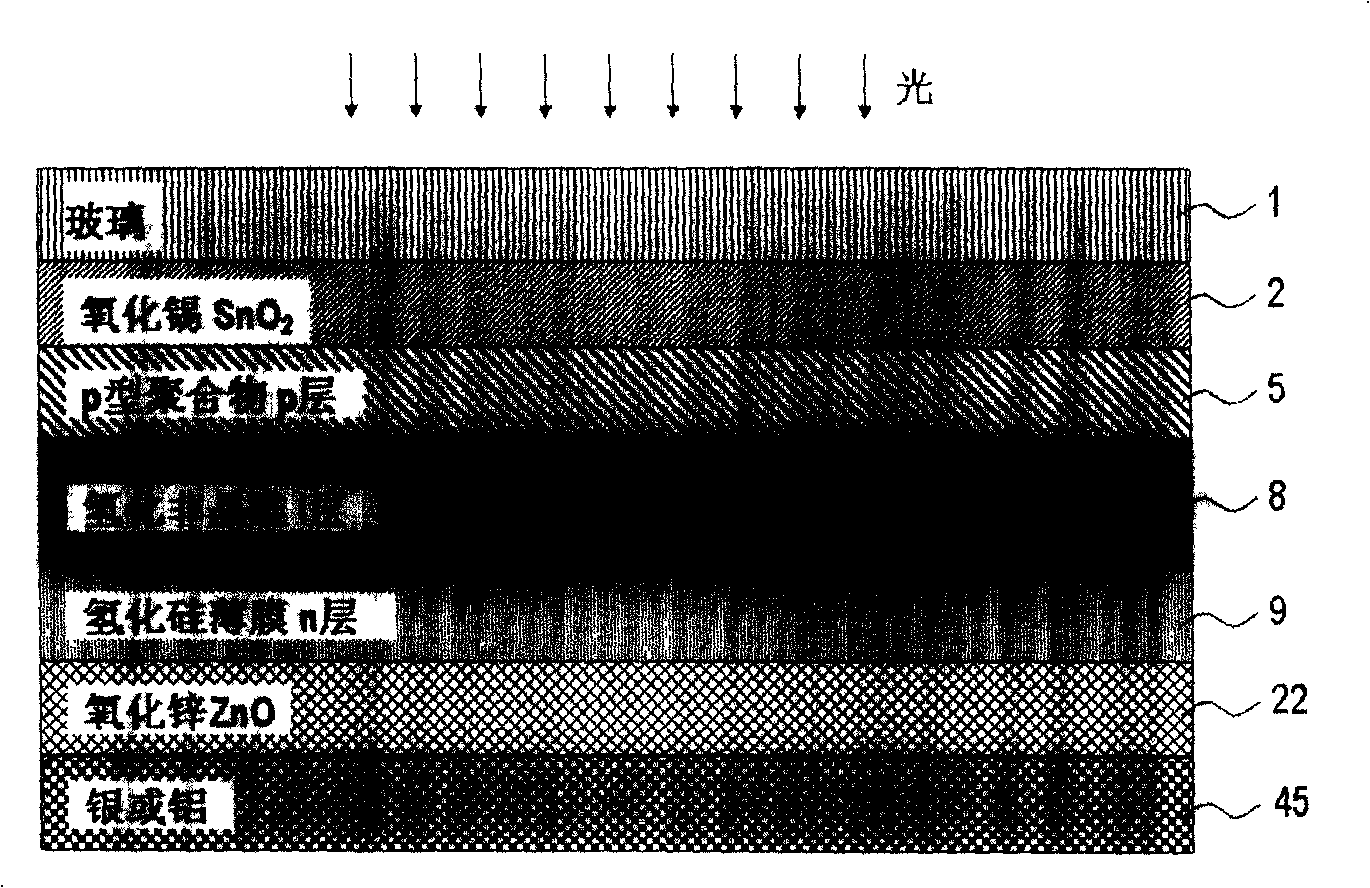

[0018] The above-mentioned p-type conductive polymer can be used as the p-layer of p-i-n-type amorphous silicon solar cells to reduce light absorption loss, thereby increasing its output power. As shown in the accompanying drawings, the structure of this type of cell includes a first layer or substrate 1 with high transparency and structural stability, a transparent conductive oxide front electrode 2 (front contact layer) formed on the substrate, a A p-layer 5 made of conductive polymer, an i-layer 8 made of non-doped hydrogenated amorphous silicon, a phosphorus-doped n-layer 9 based on hydrogenated silicon thin film, another transparent conductive film 22, a metal film 45. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com