High-strength borehole anchorage agent

A drilling anchor and high-strength technology, used in the field of high-strength drilling anchors, can solve the problems of low anchoring strength, slow material curing, and long tensile age, and achieves appropriate curing time, high early strength, and tensile age. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: get silicate mineral powder 38Kg, fly ash 13Kg, sulfoaluminate mineral powder 4Kg, silicon oxide 5Kg, agent naphthalene sulfonate formaldehyde condensate or sulfate or amine surfactant 0.5Kg, sugar Calcium or lignosulfonate 0.2Kg and cellulose ether 0.2Kg, the above materials are mixed, stirred evenly, and then sealed and packaged to obtain this product.

Embodiment 2

[0016] Embodiment two: get silicate mineral powder 52Kg, fly ash 19Kg, sulfoaluminate mineral powder 5Kg, agent naphthalene sulfonate formaldehyde condensate or sulfate or amine surfactant 1Kg, sugar calcium or lignin sulfonate salt 0.25Kg and cellulose ether 0.3Kg, mix the above materials, stir evenly, seal and package to obtain this product.

Embodiment 3

[0017] Embodiment three: get silicate mineral powder 67Kg, silicon powder 33Kg, sulfoaluminate mineral powder 6Kg, silicon oxide 38Kg, agent naphthalene sulfonate formaldehyde condensate or sulfate or amine surfactant 2.5Kg, sugar calcium Or 0.3Kg of lignosulfonate and 0.5Kg of cellulose ether, mix the above materials, stir evenly, seal and package to obtain this product.

[0018] The new material for concrete protection, repair and anchoring of the present invention is gray powder, belongs to inorganic hydraulic cementitious material, and has a density of 3.0g / cm 3 about.

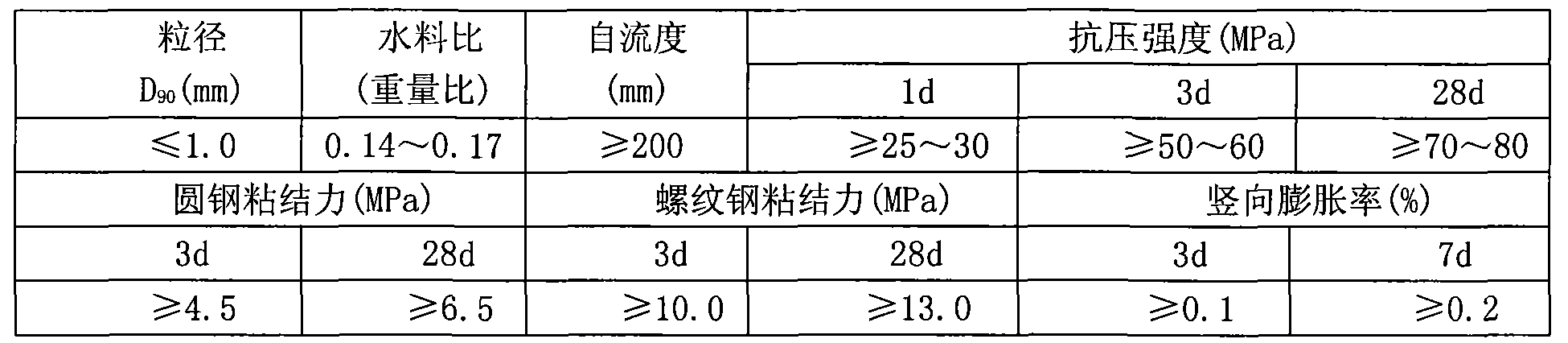

[0019] The material properties are shown in the table below:

[0020]

[0021] Note: The compressive strength test uses 70.7*70.7*70.7 specimens.

[0022] Product production method:

[0023] Equipment: material tanks, mass measuring instruments (such as scales), powder mixers, powder packaging machines.

[0024] production method:

[0025] Weigh each material as required, pour into the powder mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com