Method for coproducing vanadium pentoxide from vanadium-containing stone coal ore and fluorite

A vanadium pentoxide and coal mine technology, applied in vanadium oxide and other directions, to achieve the effect of process strengthening and smelting process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

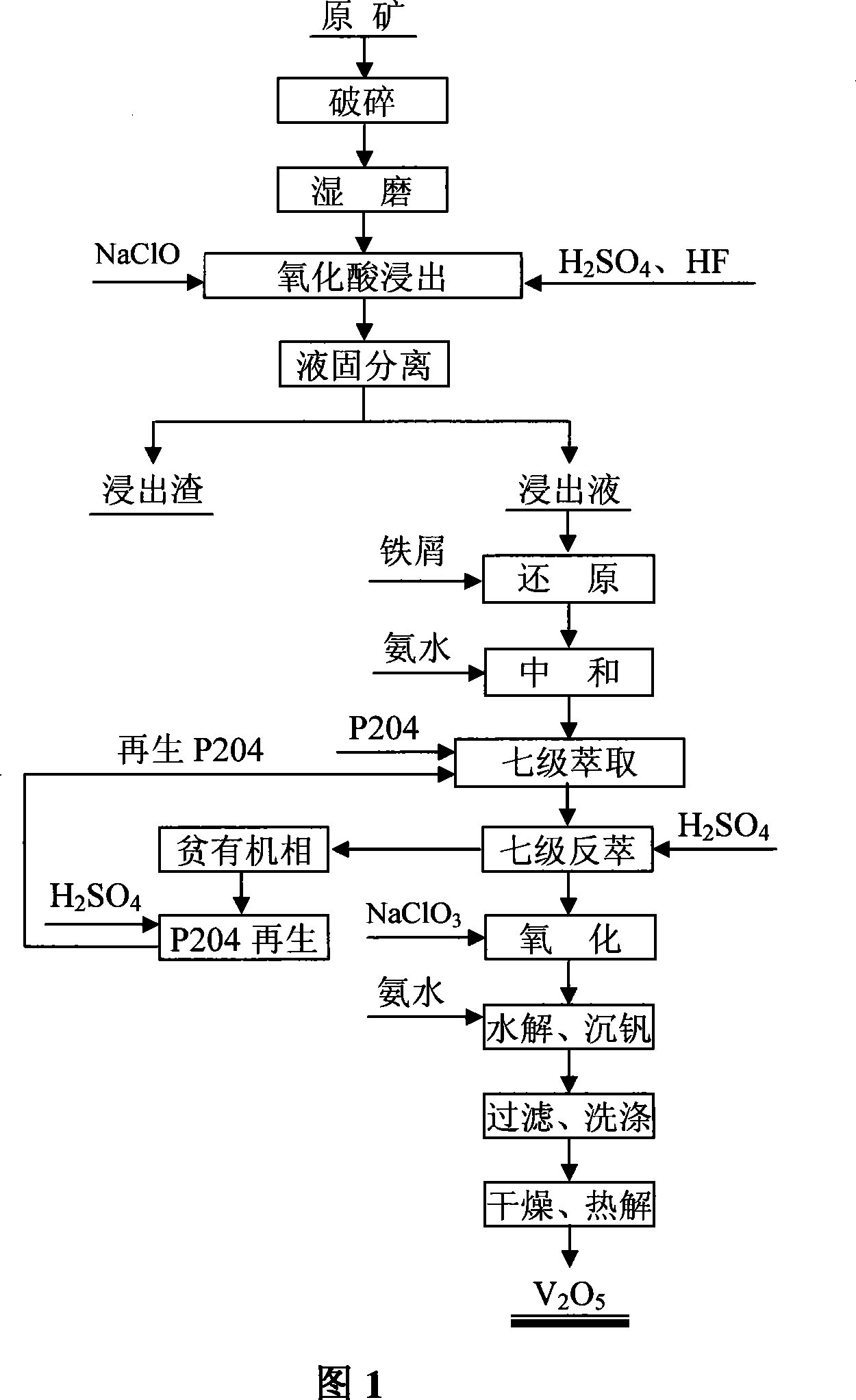

Image

Examples

Embodiment 1

[0047] Embodiment one: stone coal contains vanadium 1.84%

[0048] 1. Crush 100 kg of stone coal ore containing 1.84% vanadium and 20 kg of fluorite ore, ball mill to 200 mesh, mix with sulfuric acid solution with an acidity of 200 g / L at a liquid-solid ratio of 4:1, and continuously pump in the reaction with an acid-resistant pump In the tank, use steam heating to control the temperature in the reactor at 93°C. After 60 minutes, add 1 kg of sodium hypochlorite oxidant to the reaction tank, and let the vanadium-containing stone coal and fluorite ore react and leach in the reaction tank for 360 minutes;

[0049] 2. Use a belt-type suction filter to separate the slurry in the above reaction kettle from liquid to solid, and obtain leach slag and leachate after liquid-solid separation;

[0050] 3. In the reduction reaction tank, the iron filings reduction method is used to reduce the ferric ions in the above leachate, and the amount of iron filings added is 4.5kg;

[0051] 4. The...

Embodiment 2

[0056] Embodiment two: stone coal contains vanadium 1.0%

[0057] 1. Crush 100kg of stone coal ore containing 1.0% vanadium and 12kg of fluorite ore, ball mill to 100 mesh, mix with sulfuric acid solution with an acidity of 125 g / L at a liquid-solid ratio of 1.2:1, and continuously pump in the reaction with an acid-resistant pump In the tank, use steam heating to control the temperature in the reactor at 80°C, add 700g of sodium hypochlorite oxidant to the reaction tank after 65 minutes, let the vanadium-containing stone coal ore and fluorite ore react and leach in the reaction tank for 400 minutes;

[0058] 2. Use a belt-type suction filter to separate the slurry in the above reaction kettle from liquid to solid, and obtain leach slag and leachate after liquid-solid separation;

[0059] 3. In the reduction reaction tank, the iron filings reduction method is used to reduce the ferric ions in the above leachate, and the iron filings addition is 5kg;

[0060] 4. The leaching so...

Embodiment 3

[0065] Embodiment three: stone coal contains vanadium 0.3%

[0066] 1. Crush 100kg of stone coal ore containing 0.3% vanadium and 10kg of fluorite ore, ball mill to 60 mesh, mix with sulfuric acid solution with an acidity of 50 g / L at a liquid-solid ratio of 2:1, and continuously pump in the reaction with an acid-resistant pump In the tank, use steam heating to control the temperature in the reactor at 40°C. After 30 minutes, add 300g of sodium hypochlorite oxidant to the reaction tank, and let the vanadium-containing stone coal and fluorite ore react and leach in the reaction tank for 120 minutes;

[0067] 2. Use a belt-type suction filter to separate the slurry in the above reaction kettle from liquid to solid, and obtain leach slag and leachate after liquid-solid separation;

[0068] 3. In the reduction reaction tank, the ferric ions in the above-mentioned leaching solution are reduced by the iron filings reduction method, and the iron filings addition is 7kg;

[0069] 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com