Method for preparing facilitated transport membrane containing polyallylamine for separating acid gas

A technology that promotes the transfer of membranes and polyallylamines, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

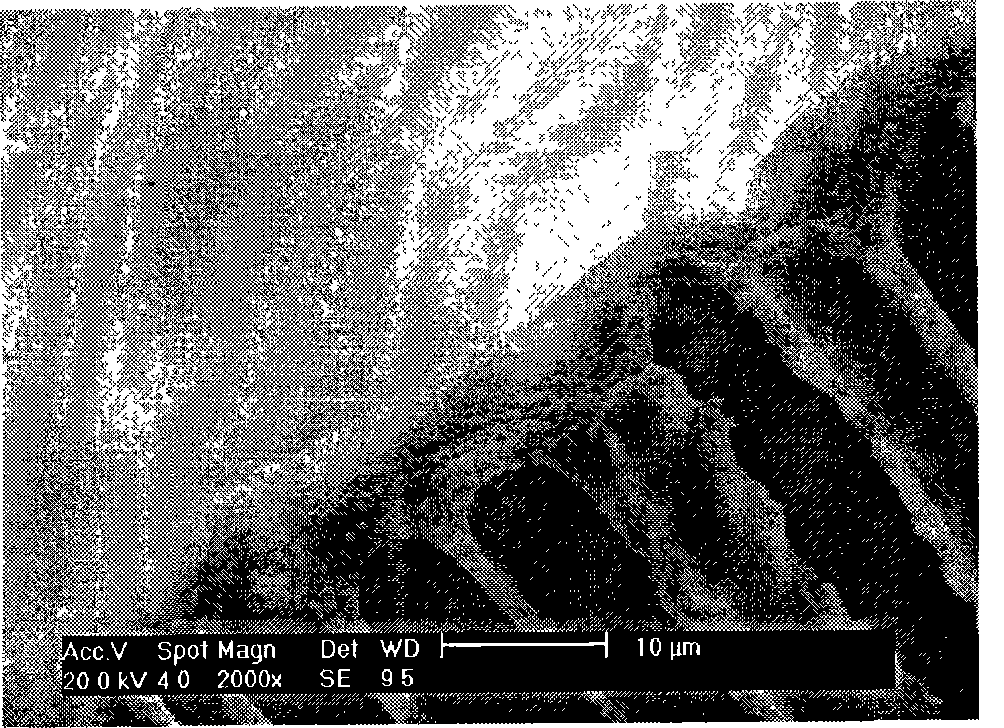

Image

Examples

Embodiment l

[0016] Weigh 172.5 grams (1.5mol) of phosphoric acid with a mass fraction of 85% and place it in a 250ml three-necked flask, add 42.75 grams of monomer allylamine (0.75mol) dropwise, and react in an oil bath at 50°C for 72 hours to synthesize poly Allylamine Phosphate. Precipitate in ethanol, and the precipitated product is crushed and dissolved in saturated potassium hydroxide methanol solution. After fully dissolving, the precipitate is filtered off, and the solution is vacuum-dried at 60° C. to obtain polyallylamine. Prepare a polyallylamine aqueous solution with a mass concentration of 5%, and simultaneously prepare a polyvinyl alcohol aqueous solution with a mass concentration of 1%, wherein the molecular weight of polyvinyl alcohol is 75000, according to the volume of polyallylamine and polyvinyl alcohol aqueous solution Ratio 5:95 to prepare 4ml casting liquid, the size is 22cm * 13cm polyethersulfone flat membrane (nominal molecular weight cut-off is 30000) soak in the...

Embodiment 2

[0018] The polyallylamine aqueous solution with a mass concentration of 5% and the polyvinyl alcohol aqueous solution with a mass concentration of 1% prepared in Example 1 were used. According to the volume ratio of polyallylamine and polyvinyl alcohol aqueous solution of 12:88, prepare 4mL of casting solution, treat the polyethersulfone flat membrane according to the base film size and pretreatment method in Example 1, and coat the prepared 4mL of casting solution On the treated polyethersulfone flat membrane, dry at a temperature of 30°C and a relative humidity of 40%, to obtain a polyallylamine-containing facilitated transport membrane for separating acid gases. With mixed gas 10vol% CO 2 / 90vol%CH 4 and 20vol% CO 2 / 80vol%N 2 Performance test it. Test result: for 10vol% CO 2 / 90vol%CH 4 Mixed gas system, when the feed gas pressure is 83.5~1291.3cmHg (0.1~1.7MPa), CO 2 / CH 4 Separation factor 120~50, CO 2 Penetration rate (90~20)×10 -6 cm 3 (STP)cm -2 the s -1 ...

Embodiment 3

[0020] Using the 5% polyallylamine aqueous solution with a mass concentration prepared in Example 1, simultaneously prepare a 1% polyvinylpyrrolidone aqueous solution, wherein the polyvinylpyrrolidone has a molecular weight of 100,000, according to polyallylamine The volume ratio of polyvinylpyrrolidone aqueous solution is 5:95 to prepare 3ml casting liquid, according to the size of the base membrane and the pretreatment method in Example 1, the polysulfone flat membrane is processed, and the prepared 3mL casting liquid is coated on the treated polysulfone On the flat membrane, dry at a temperature of 30° C. and a relative humidity of 40%, to obtain a polyallylamine-containing facilitated transport membrane for separating acid gases. With mixed gas 10vol% CO 2 / 90vol%CH 4 and 20vol% CO 2 / 80vol%N 2 Performance test it. Test result: for 10vol% CO 2 / 90vol%CH 4 Mixed gas system, when the feed gas pressure is 83.5~1051.2cmHg (0.1~1.4MPa), CO 2 / CH 4 Separation factor 80-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com