A reset compound Mg-Si-Sn base thermal electric material and its making method

An in-situ composite, thermoelectric material technology, applied in the direction of thermoelectric device node lead-out material, thermoelectric device manufacturing/processing, etc., can solve the problem that the second phase is not a good thermoelectric material, the second phase distribution is uncertain, difficult Control the two-phase distribution and other issues to achieve the effects of reducing interface pollution, reducing thermal conductivity, and improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw materials are stoichiometrically compared to Mg 2 Si 0.5 sn 0.5 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1100°C and fully melt it, then quickly move the ceramic tube to a furnace at 860°C, and then cool it to 780°C at a cooling rate of 1°C / min. Annealed at 600°C for 100h, then mechanically ball-milled the material, then hot-pressed in vacuum at 600°C and 80MPa for 2h. The in-situ composite Mg-Si-Sn based thermoelectric material is obtained.

[0020] RigakuD / MAX-2550PC X-ray polycrystalline diffractometer (XRD) was used to analyze the phase of the sample prepared in this example, and the sample was obtained as a composite material of Si-rich phase and Sn-rich phase.

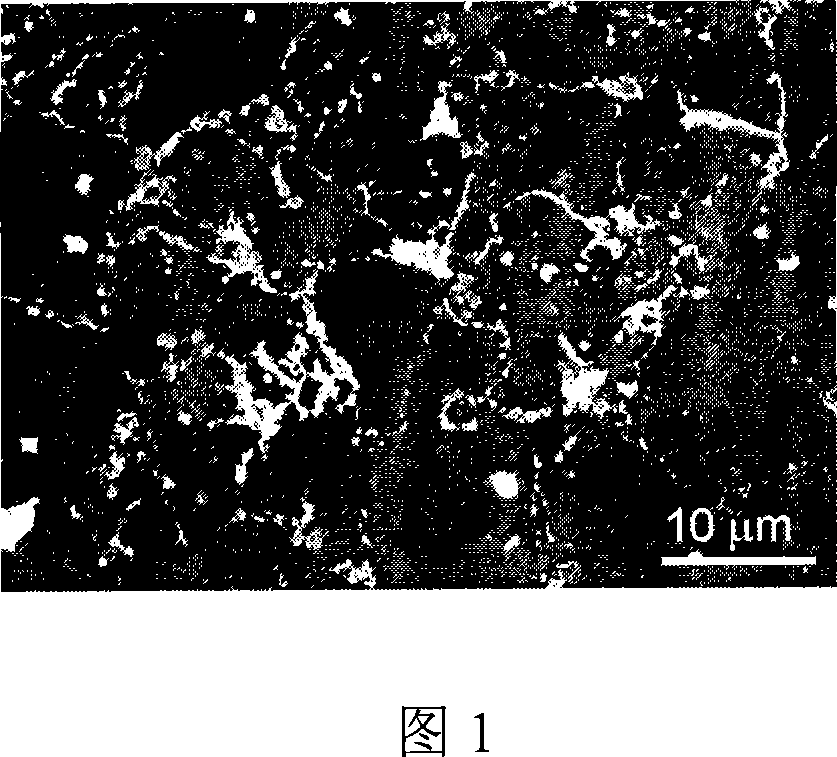

[0021] Using FEI Sirion field emission scanning electron microscope (FESEM) to observe the microstructure of the material, as shown in Figure 1, the surface of the sample is coated with a thin layer of 200nm, XRD and energy spectrum analysi...

Embodiment 2

[0024] Raw materials are stoichiometrically compared to Mg 1.992 La 0.008 Si 0.52 sn 0.48 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1200°C and fully melt it, then quickly move the ceramic tube to a furnace at 900°C, and then cool it to 780°C at a cooling rate of 1°C / min. Annealed at 600°C for 150h, then mechanically ball-milled the material, and then vacuum hot-pressed at 600°C and 80MPa for 1h. Microstructure observation shows that the surface of the sample is covered with a 500nm thin layer. XRD and energy spectrum analysis show that the Si:Sn atomic content ratio of the Sn-rich phase is 0.35:0.65, and the Si-rich phase Si:Sn atomic content ratio is 0.7:0.3. The performance test shows that the thermal conductivity of the composite thermoelectric material is κ=1.9W·m at room temperature -1 K -1 , the Z value is 1000×10 at 800K -6 K -1 .

Embodiment 3

[0026] Raw materials are stoichiometrically compared to Mg 1.98 La 0.02 Si 0.55 sn 0.45 After calculation and weighing, put it in a ceramic tube protected by Ar gas, heat it in a furnace at 1150 °C and fully melt it, then quickly move the ceramic tube to a furnace at 900 °C, and then cool it to 780 °C at a cooling rate of 1 °C / min. Then anneal at 600°C for 100h, and then mechanically ball mill the material, then vacuum hot press at 700°C and 80MPa for 2h. Microstructure observation shows that the surface of the sample is covered with a 100nm thin layer. XRD and energy spectrum analysis show that the Si:Sn atomic content ratio of the Sn-rich phase is 0.4:0.6, and the Si-rich phase Si:Sn atomic content ratio is 0.7:0.3. The performance test shows that the thermal conductivity of the composite thermoelectric material is κ=2.0W·m at room temperature -1 K -1 , the Z value is 960×10 at 800K -6 K -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com