Composite stone slab

A technology of crystal granite slabs and crystal granite, which is applied in the direction of covering/lining, construction, building construction, etc., can solve the problems of low strength and hardness, poor fire resistance, easy deformation, etc., and achieve light weight, strong environmental protection, flatness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

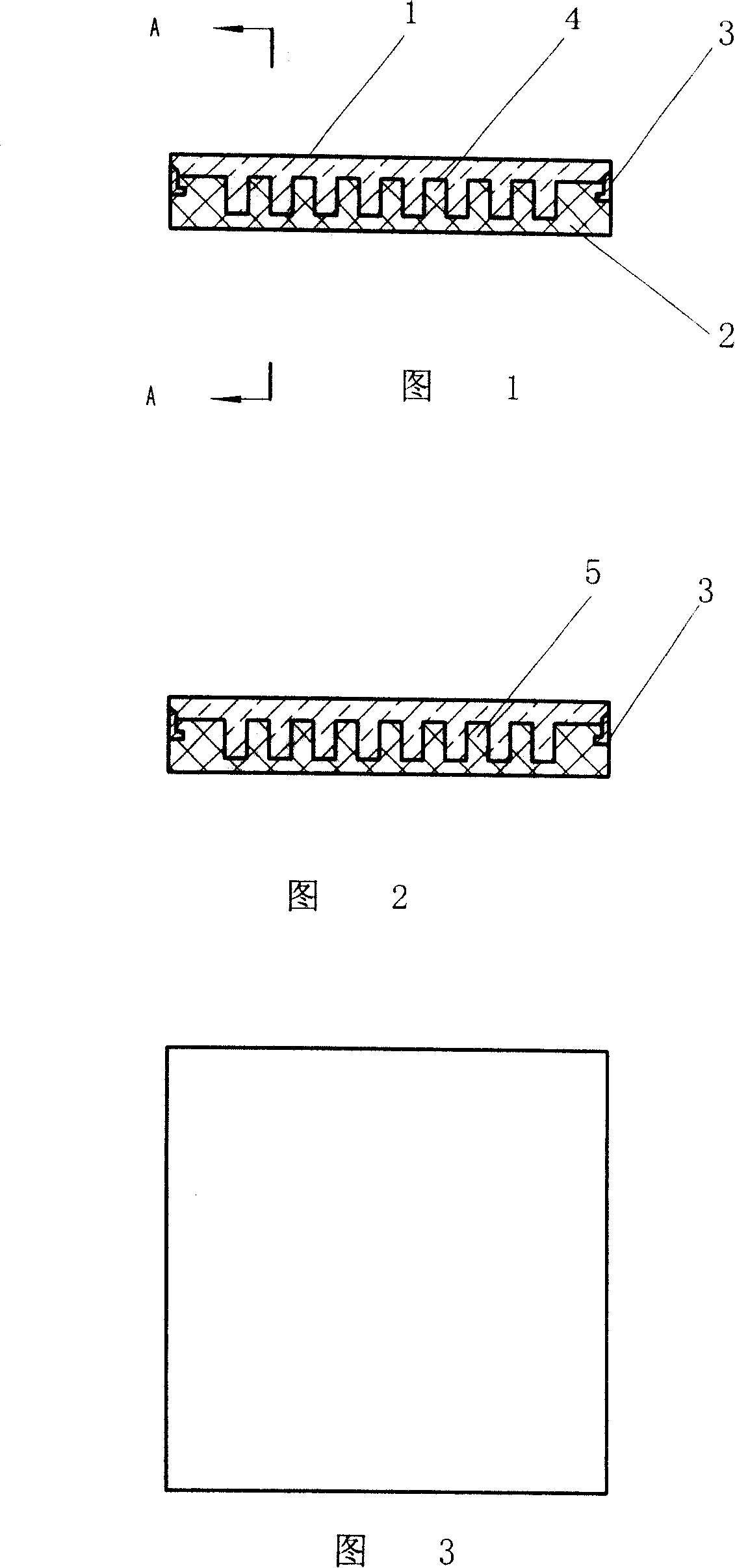

[0015] Referring to Figure 1, Figure 2, Figure 3 (Figure 1 and Figure 2 are product cross-sectional views), the composite crystal stone slab of the present invention has a substrate layer 2, on which the crystal stone decorative layer 1 is composited. The composite of the layer and the decorative layer adopts conventional technology. The substrate layer is provided with a plurality of longitudinal convex ridges 4 and a plurality of transverse convex ridges 5, the substrate layer is composed of fiber cloth or non-woven fabric and unsaturated resin, and the crystal stone decoration layer is composed of quartz sand and The resin is mixed and solidified, and a metal frame 3 is arranged at the periphery of the crystal stone slab. In this embodiment, the thickness of the substrate layer may be 2-5 mm, and the thickness of the granite decoration layer may be 0.5-2 mm (excluding the size of the bump). The arrangement of the longitudinal convex ridge and the transverse convex ridge can imp...

Embodiment 2

[0018] This embodiment is an improvement on the basis of the above embodiments. In this embodiment, the composite of the substrate layer and the decorative layer adopts conventional techniques, including batching, mixing, mold, curing, grinding, and polishing steps. The resins and curing agents used adopt conventional products and technologies, and the surface treatment of crystal stone slabs adopts conventional technologies, which will not be described in detail here.

[0019] In order to produce composite granite slabs closer to the granite pattern, the granite decorative layer of this embodiment includes the following raw materials, and the weight percentage of the raw materials is:

[0020] Resin 30%

[0021] Quartz coarse sand 20%

[0022] Quartz fine sand 30%

[0023] Glass particles 4%

[0024] Silica 1%

[0025] Alumina 1%

[0026] Titanium dioxide 0.1%

[0027] The rest are fillers. The filler can be made of 320 mesh fine stone powder; among them, the proportion of resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com