High ash melting point coal seed gasification method and device thereof

A technology with high ash melting point and coal type, which is applied in the direction of granular/powder fuel gasification, etc., can solve the problems of increasing nitrogen oxide emissions of atmospheric pollutants, insufficient combustion, large temperature gradient, etc., and achieves simple structure and convenient operation. , the effect of increasing the average temperature level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

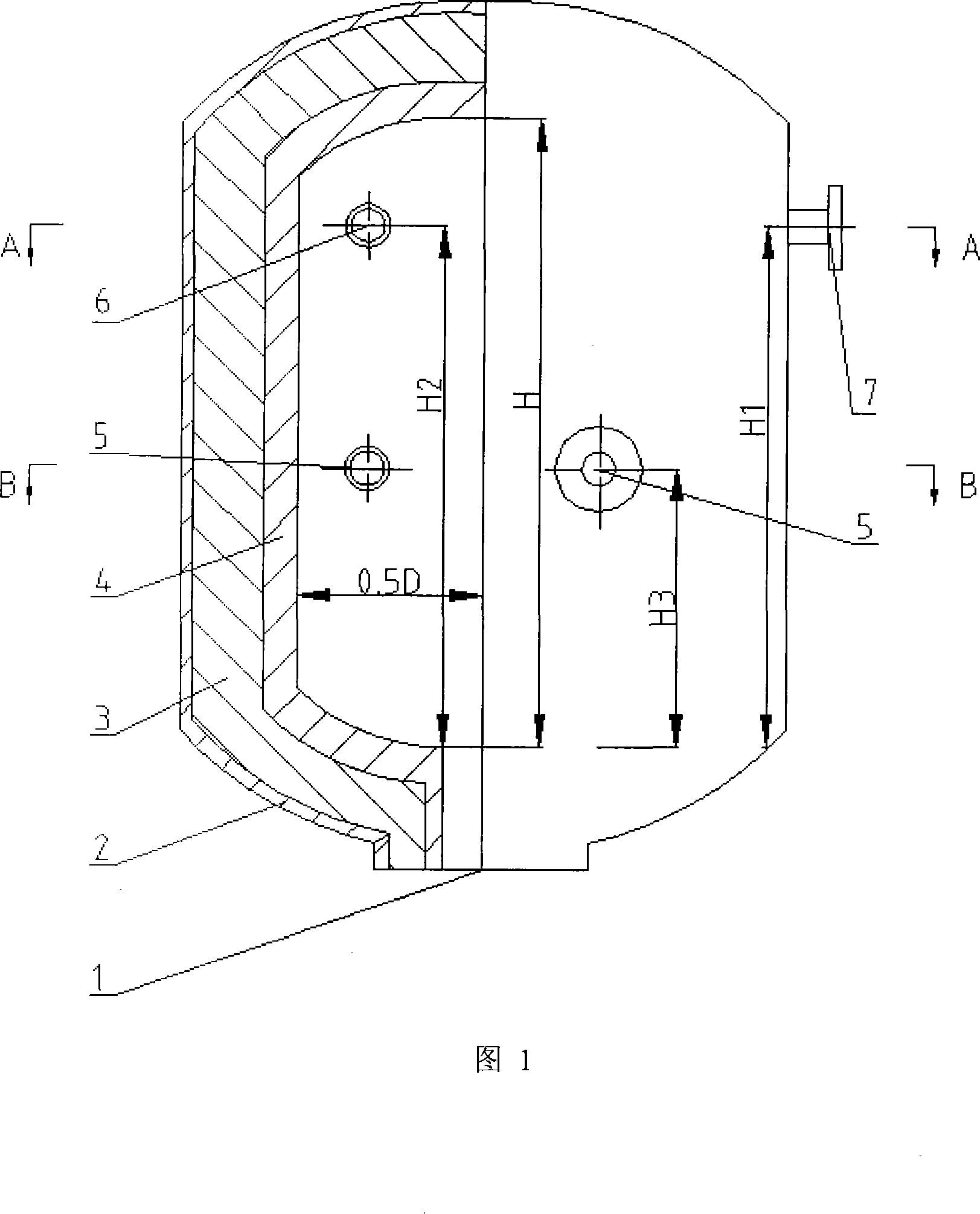

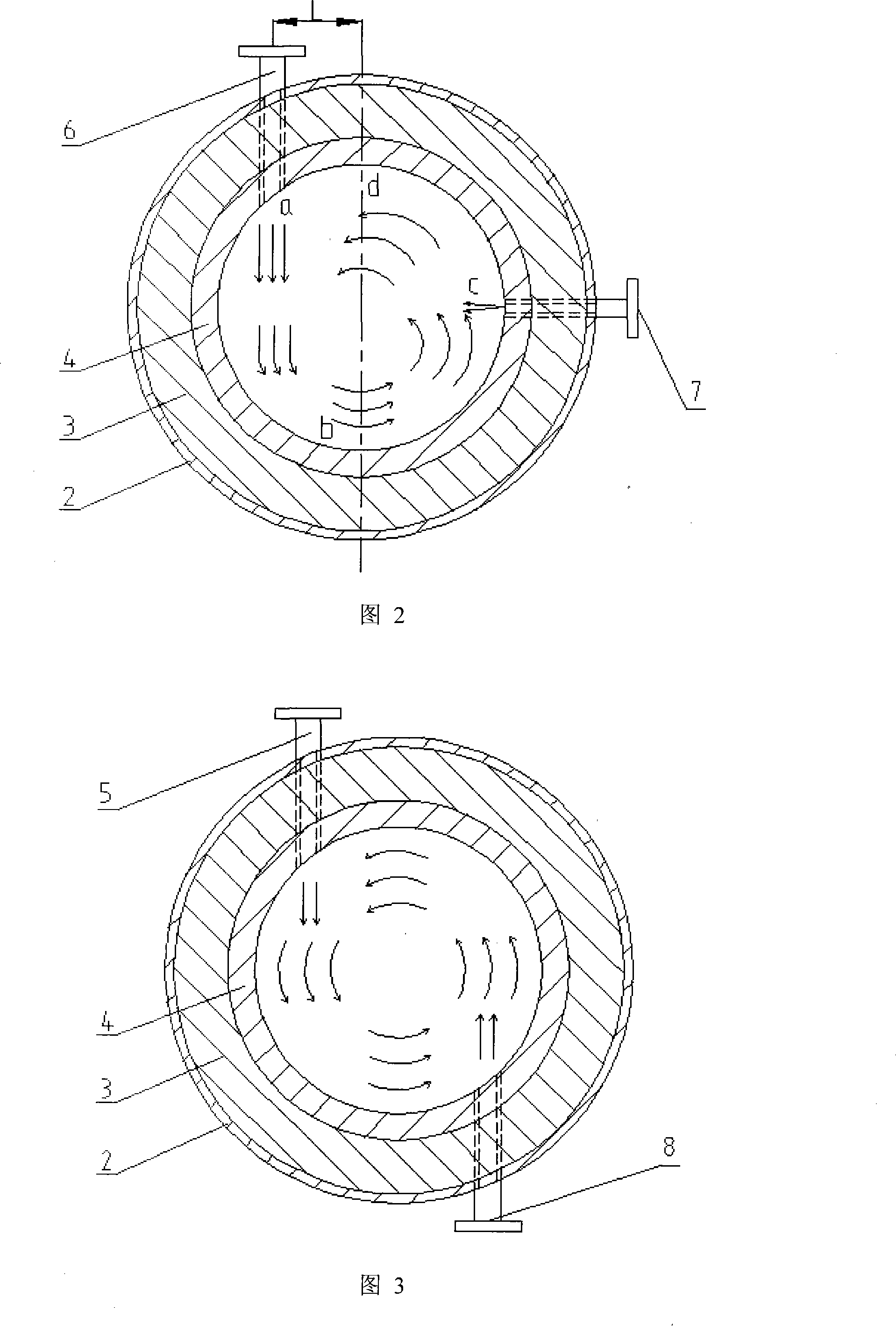

[0024]Fig. 1 is a schematic structural view of the high ash melting point coal gasification method and device embodiment 1 of the present invention; Fig. 2 is a sectional view A-A of the schematic structural view of embodiment 1; Fig. 3 is a sectional view B-B of the schematic structural view of embodiment 1. In this embodiment, the gasifier is composed of a metal shell 2 , a thermal insulation layer 3 , a refractory liner 4 , an oxidant nozzle 6 , a pulverized coal nozzle 7 , and steam nozzles 5 and 8 . The metal shell 2 can withstand 0.1-4Mpa at 20°C-400°C; the ratio of the height to the inner diameter of the gasifier D:H=1:1.5, the height H1 of the pulverized coal nozzle 7=0.2H, and the height H2 of the oxidant nozzle 6= 0.2H, the height H3 of the steam nozzles 5 and 8 = 0.5H; the oxidant nozzle 6 and the steam nozzle 5 are on the same vertical plane, and the steam nozzles 5 and 8 are opposite to each other on the horizontal circle. The oxidizing agent is selected from indu...

Embodiment 2

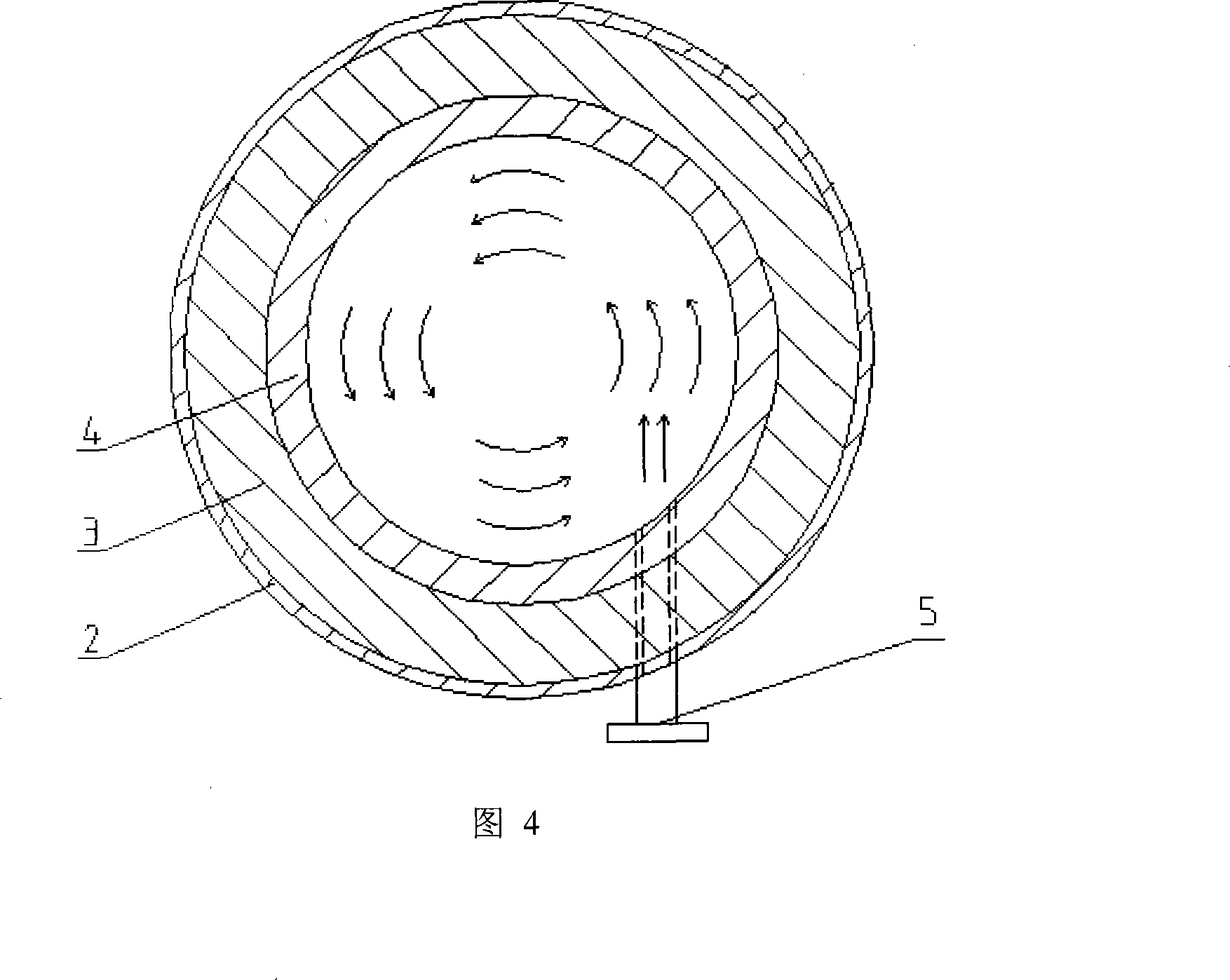

[0028] In this embodiment, the overall structure of the gasifier is the same as that of Embodiment 1, the difference is that the position of the pulverized coal nozzle 7 is changed, as shown in Figure 2, and it is placed on the bcd arc section on the A-A view plane of Figure 1 Move, or move down the position of the pulverized coal nozzle 7 so that its height is lower than the oxidizer nozzle 6; or delete one of the two steam nozzles 5 and 8 in the middle and lower section of the furnace body at the same time, as only the steam nozzle 5 is left, as As shown in Figure 4; or increase the steam nozzles in the middle and lower section of the furnace body to three to four to form tangential swirl jets in the same direction. In addition, other furnace structure and parameters are not changed. This embodiment can also achieve the advantages of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com