Hydrogen chloride whole reclaiming zero discharging technique and device for PVC producing process

A production process, hydrogen chloride technology, applied in the addition preparation of hydrogen halide, organic chemistry and other directions, can solve the problems of the quality of vinyl chloride refining, difficult to contain mercury hydrochloric acid, environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

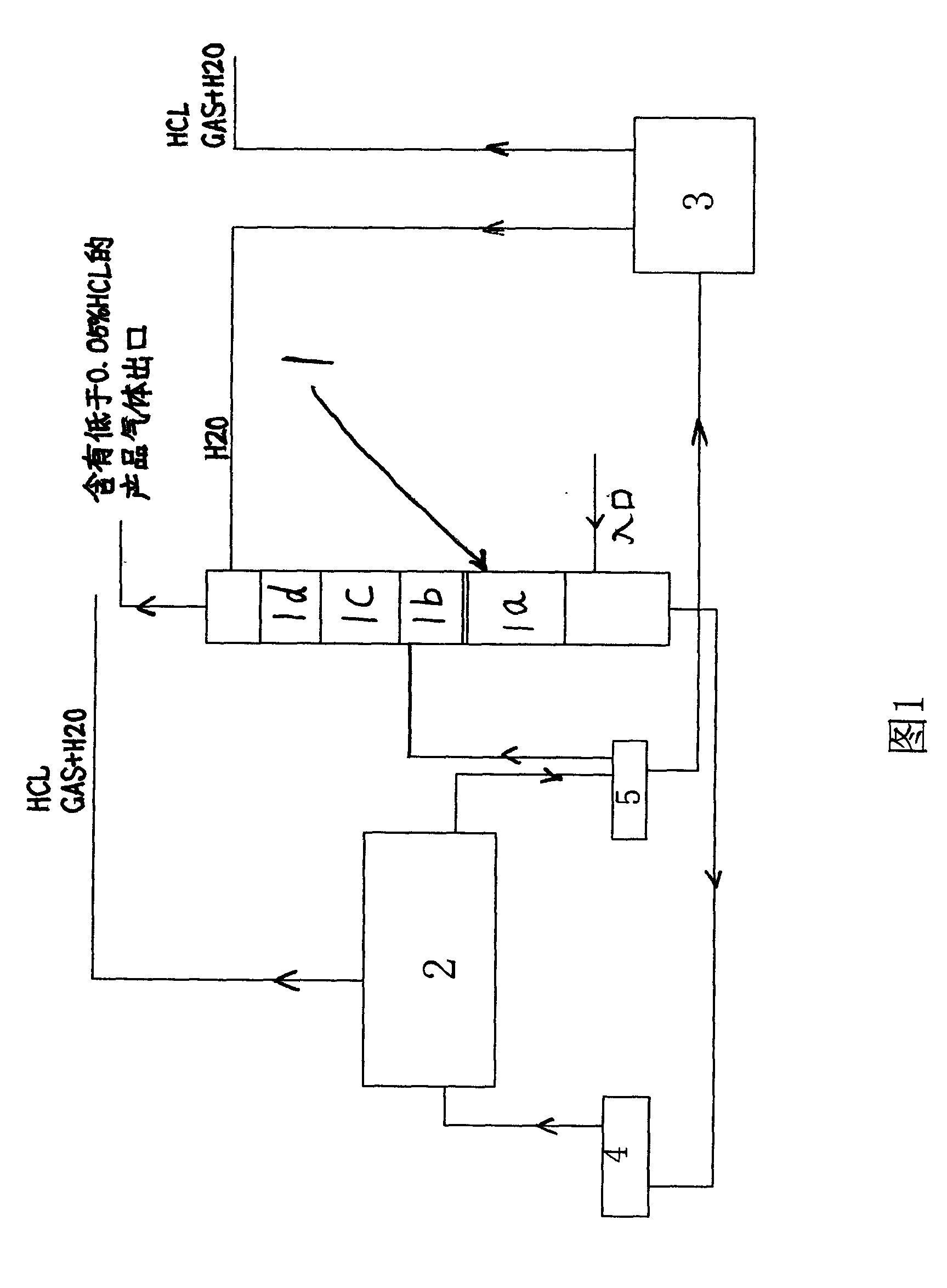

[0063] 5400m at 40°C with a pressure of 10kPa 3 / h The mixed gas of vinyl chloride containing hydrogen chloride enters from the lower part of the combined tower 1, and first passes through an isothermal absorption zone 1a, the temperature of the mixed gas of vinyl chloride containing hydrogen chloride gradually decreases, and part of the hydrogen chloride gas is absorbed. The absorber used is a proprietary graphite falling film absorber. Hydrogen chloride gas is absorbed after full contact with the liquid film evenly distributed on the surface of the tube (or short hole), and the heat released is removed by the cooling water on the shell side.

[0064] The mixed gas passing through the isothermal absorption zone 1a enters the upper concentrated acid absorption zone 1b, which is a layer of packing zone. The mixed gas passing through the isothermal absorption zone 1a enters from the bottom of a layer of packing area, passes through the free space in the filler gap of the packing a...

Embodiment 2

[0074] Other steps and processing condition are identical with embodiment 1, difference is: in the concentrated sulfuric acid desorption method:

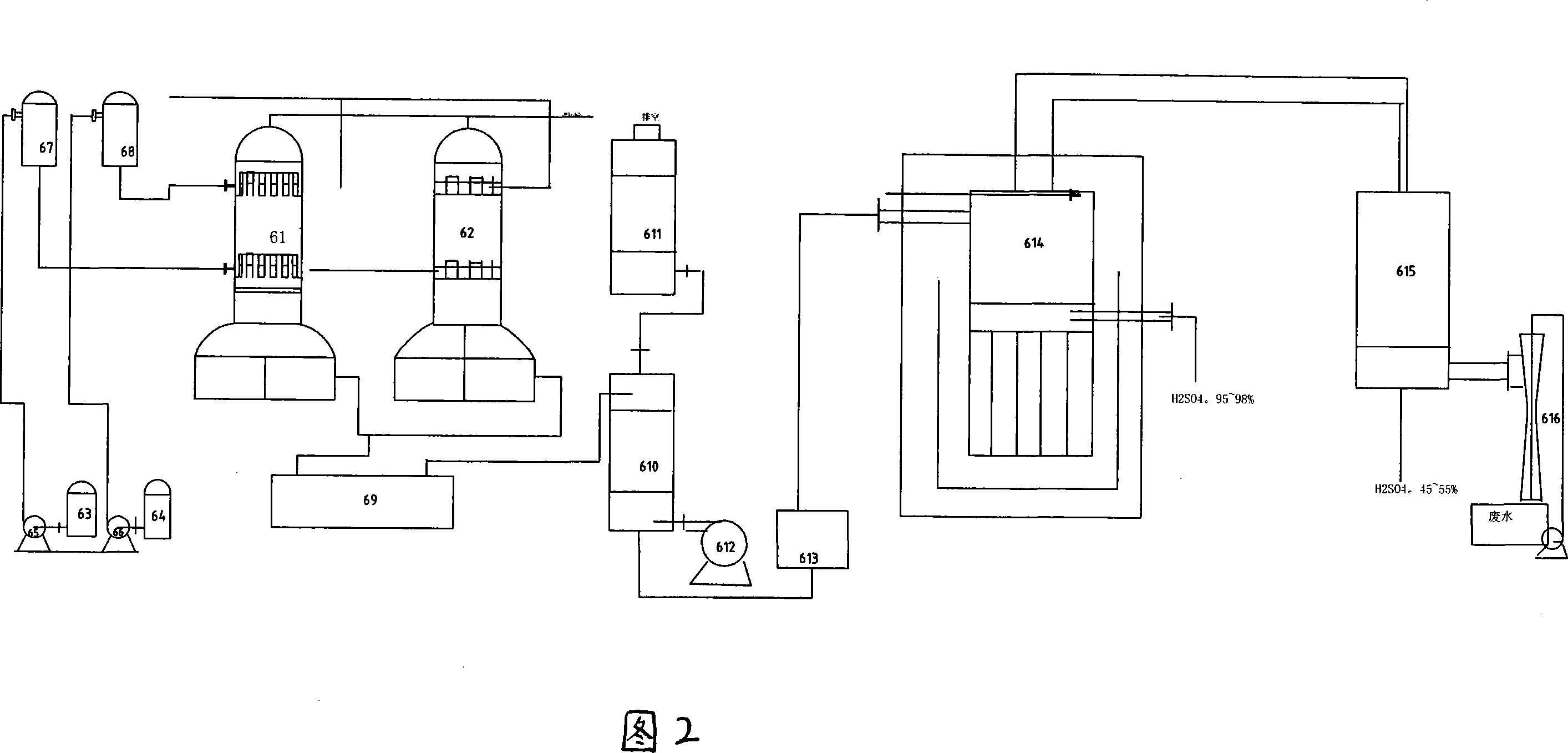

[0075] 21% dilute hydrochloric acid and 98% concentrated sulfuric acid enter the hydrochloric acid tank 63 and the sulfuric acid tank 64 respectively, and then are pumped into the hydrochloric acid head tank 67 and the sulfuric acid head tank 68 by the hydrochloric acid pump 65 and the sulfuric acid pump 66 respectively. When the liquid return pipe is normal, the hydrochloric acid in the hydrochloric acid high level tank 67 is adjusted and metered by the flow meter and then enters the upper part of the extractor 61, wherein the volume ratio of concentrated sulfuric acid to dilute hydrochloric acid is 3:1, and then the sulfuric acid in the sulfuric acid high level tank 68 is After the flow is adjusted and metered, it enters the middle part of the extractor 61. The two acids overflow and mix continuously in the tank of the extractor 61...

Embodiment 3

[0079] Other steps and processing condition are identical with embodiment 1, difference is: in the concentrated sulfuric acid desorption method:

[0080] 19% dilute hydrochloric acid and 98% concentrated sulfuric acid enter the hydrochloric acid tank 63 and the sulfuric acid tank 64 respectively, and then are pumped into the hydrochloric acid head tank 67 and the sulfuric acid head tank 68 by the hydrochloric acid pump 65 and the sulfuric acid pump 66 respectively, and the overflow of the two head tanks When the liquid return pipe is normal, the hydrochloric acid in the hydrochloric acid high level tank 67 is adjusted and metered by the flow meter and then enters the upper part of the extractor 61, wherein the volume ratio of concentrated sulfuric acid to dilute hydrochloric acid is 4:1, and then the sulfuric acid in the sulfuric acid high level tank 68 is After the flow is adjusted and metered, it enters the middle part of the extractor 61. The two acids overflow and mix conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com