Multi-layer heat-insulating membrana paster

A technology of thermal insulation film and patch, applied in the direction of layered products, synthetic resin layered products, optics, etc., can solve the problems of unsatisfactory use of thermal insulation film and patch, reduced thermal insulation effect, and poor light resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

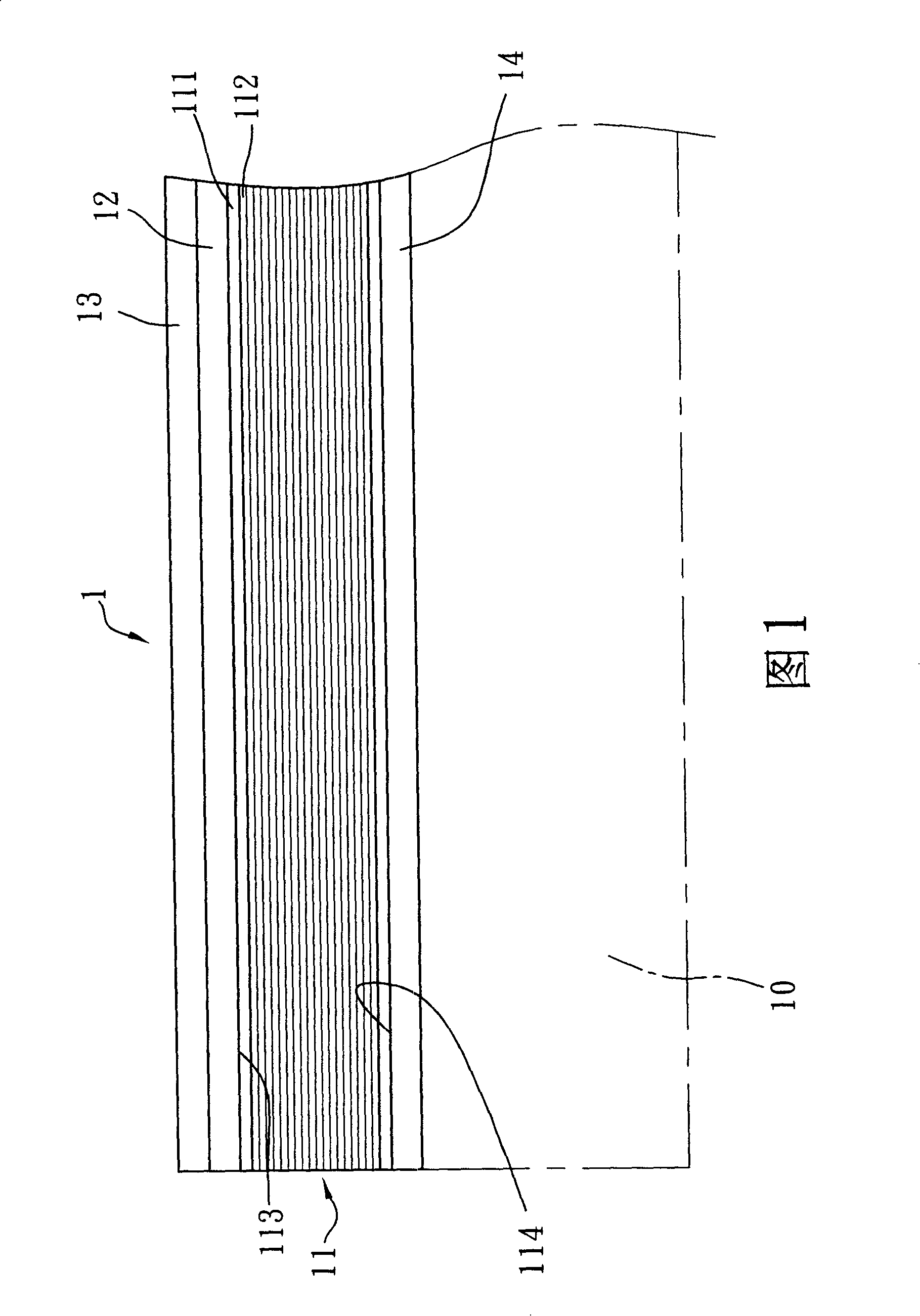

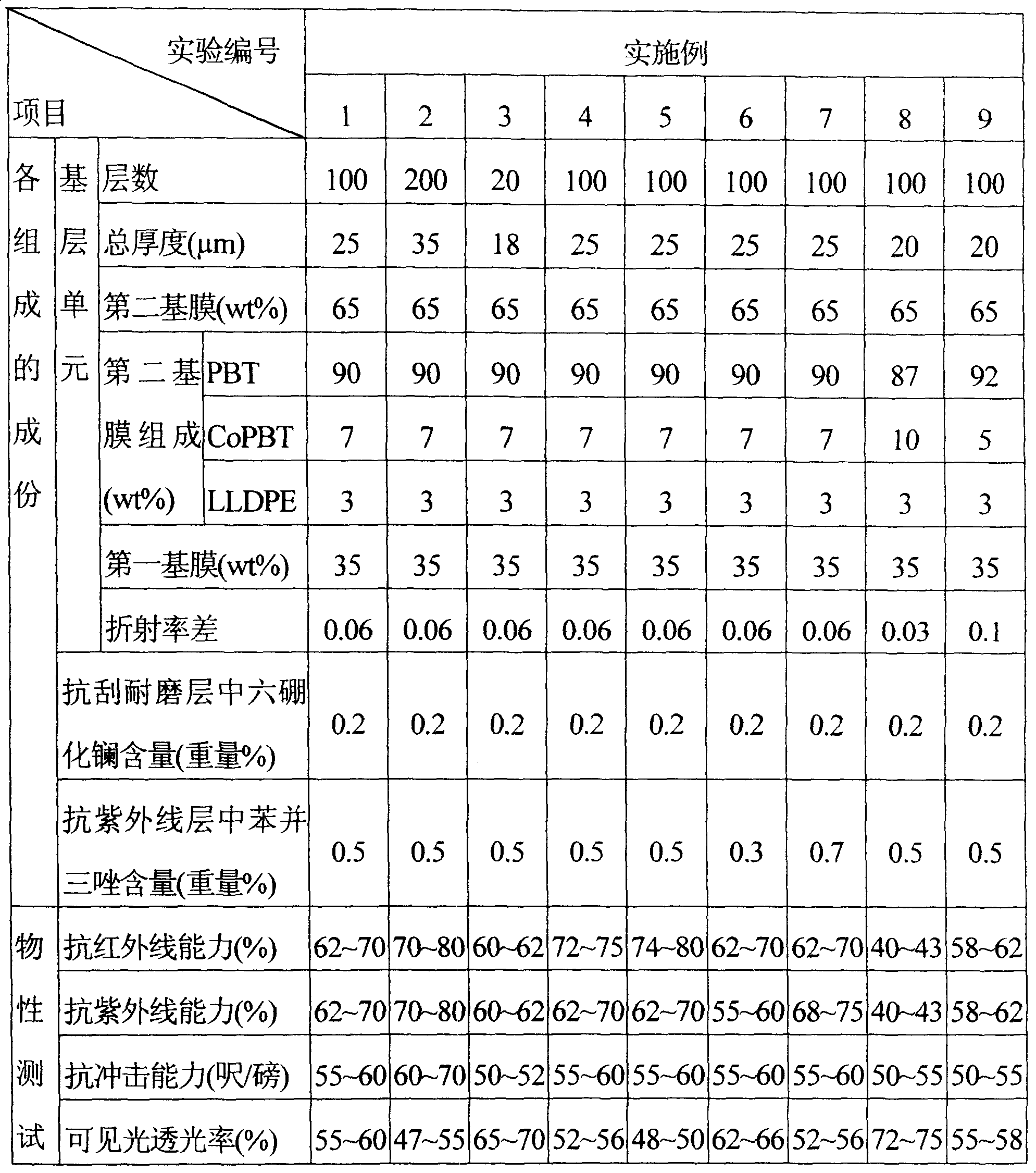

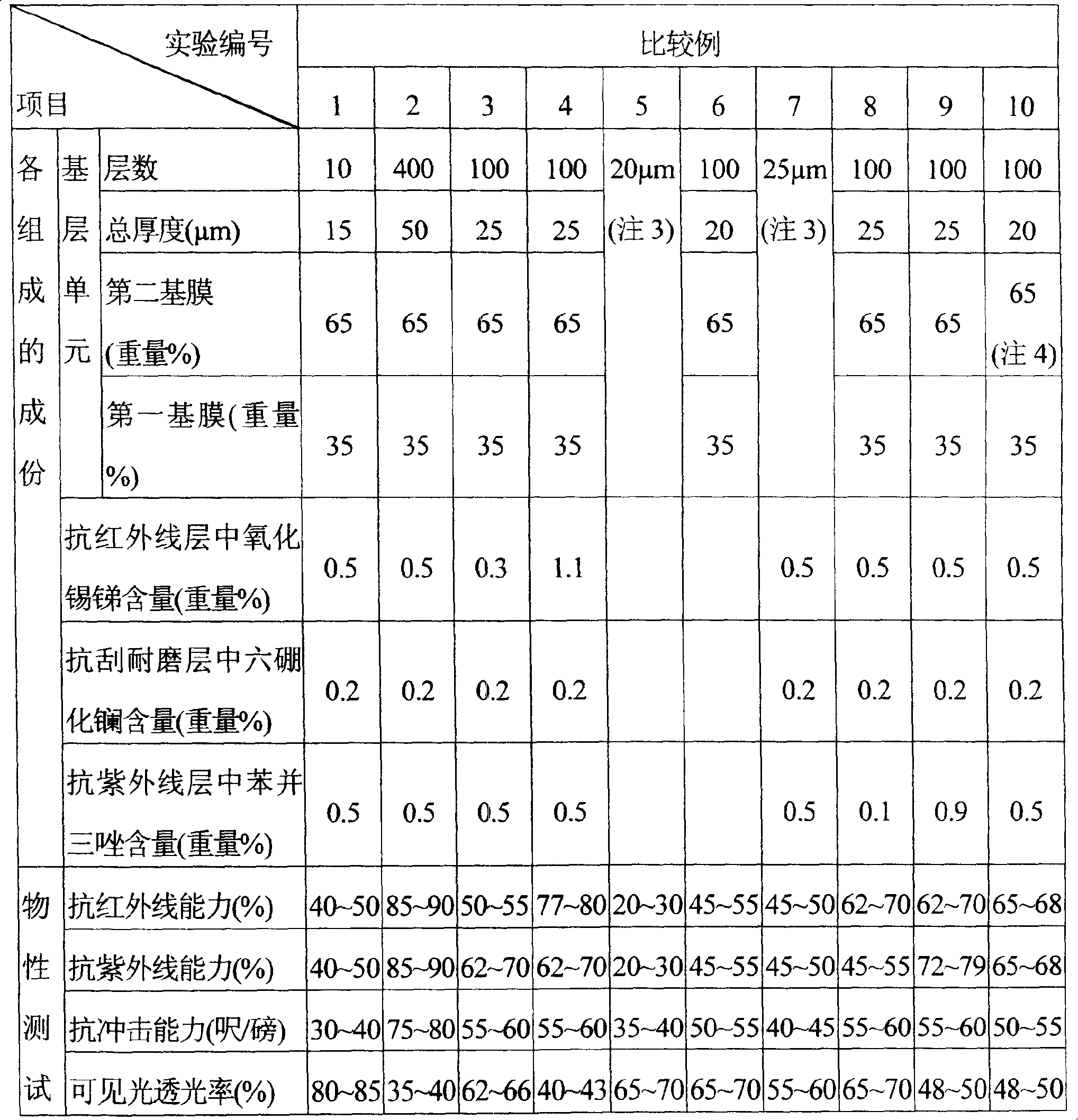

[0016] Referring to Fig. 1, the multilayer thermal insulation film patch 1 of this embodiment can be pasted on a base material 10 such as glass, lens, etc., comprising: a basic unit 11, an anti-infrared layer 12, a scratch-resistant and wear-resistant Layer 13, and an anti-ultraviolet layer 14, the base unit 11 is formed by alternately stacking a plurality of spaced first base films 111 and a plurality of second base films 112 interposed between adjacent first base films 111, the above-mentioned first base film The total number of films of the first and second base films 111, 112 is 100 layers. Overall, the base unit 11 has a first surface 113 adjacent to the anti-infrared layer 12, and a second surface adjacent to the anti-ultraviolet layer 14. 114, and the thickness of the outermost layer forming the first or second surface 113, 114 in the aforementioned base film 111, 112 is greater than that in the middle, and the anti-ultraviolet layer 14 can be directly attached to the su...

Embodiment 2

[0024] The composition ratio and processing conditions of the components of Example 2 of the present invention are roughly the same as those of Example 1, the difference being that the number of layers of the base unit 11 is increased to 200 layers, and due to the increase in the number of layers, the total thickness of the base unit 11 increased to 35 μm. After manufacturing, various tests such as infrared resistance, ultraviolet resistance, impact resistance, and visible light transmittance were also carried out. The experimental results are also shown in Table 1.

Embodiment 3

[0026] The composition ratios and processing conditions of Example 3 of the present invention are also the same as those of Example 1, except that the number of layers of the base unit 11 is reduced to 20 layers, and the overall thickness of the base unit 11 is reduced to 18 μm. After manufacturing, various tests such as infrared resistance, ultraviolet resistance, impact resistance, and visible light transmittance were also carried out. The experimental results are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com