Subsection heat-taking type overlapping heat pump

A cascading heat pump technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of unit performance index reduction, large cooling medium flow, and initial temperature that cannot be lowered at will, so as to reduce temperature difference and improve performance index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

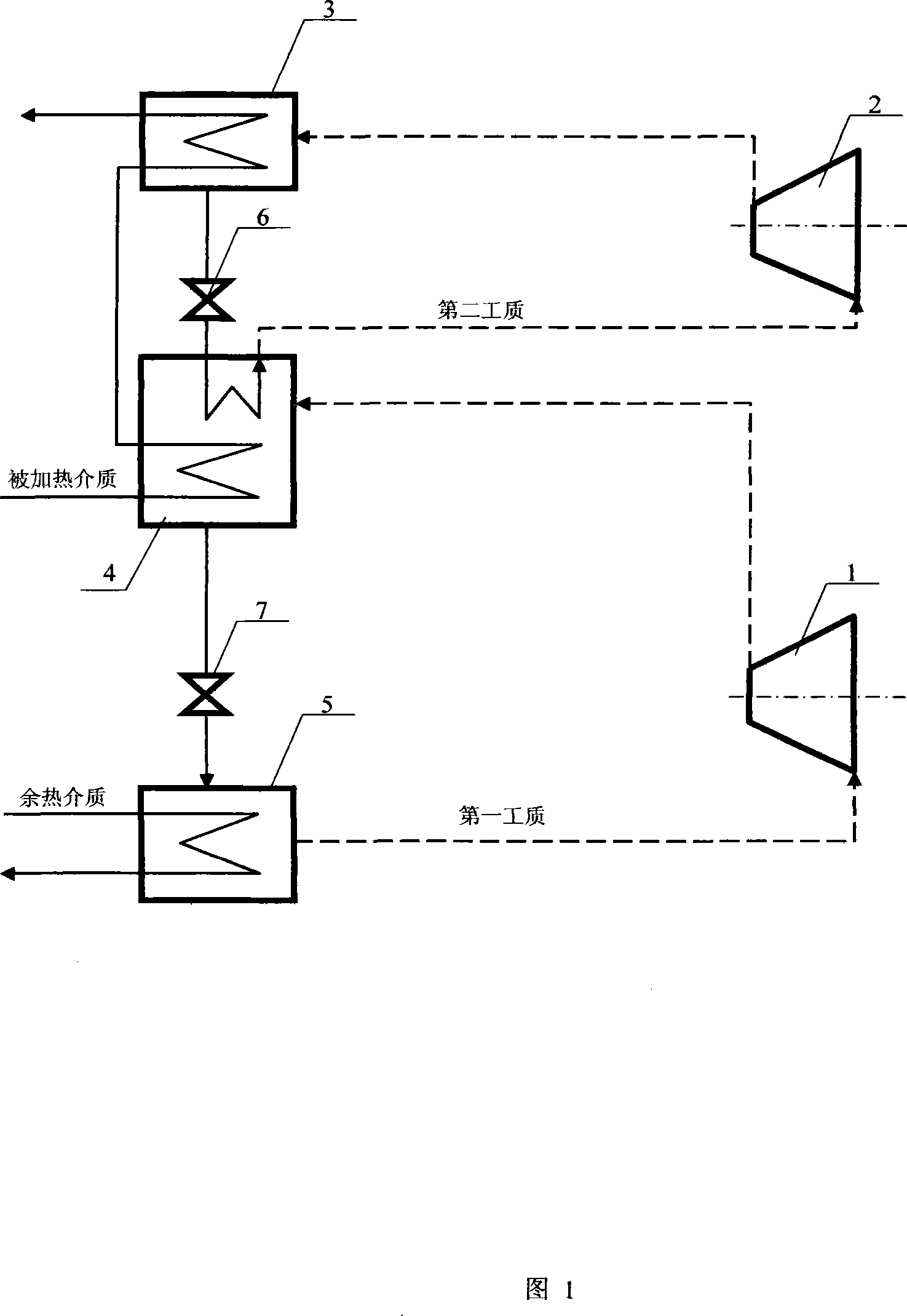

[0021] Fig. 1 is provided according to the present invention, variable condensing-evaporator is the two-stage heat-taking type cascade heat pump of composite condensing-evaporator scheme, and it realizes the present invention like this:

[0022]Basic components such as compressor (1), compound condensation-evaporator (4), evaporator (5) and throttle valve (7) constitute the flow and structure of the low-temperature heat pump—the compressor (1) works through the first working fluid The steam channel is connected to the composite condensation-evaporator (4), the composite condensation-evaporator (4), and the composite condensation-evaporator (4) is connected to the evaporator (5) through the throttle valve (7), and the evaporator (5) also There is a first working medium working steam channel connected to the compressor (1), the evaporator (5) also has a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com