Method for preparing organic modified silicate mineral clay

A technology of silicate minerals and clay, applied in the field of clay silicates, can solve the problems of undisclosed specific components of modifiers, lack of necessary performance indicators of modified attapulgite, etc., and achieve the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

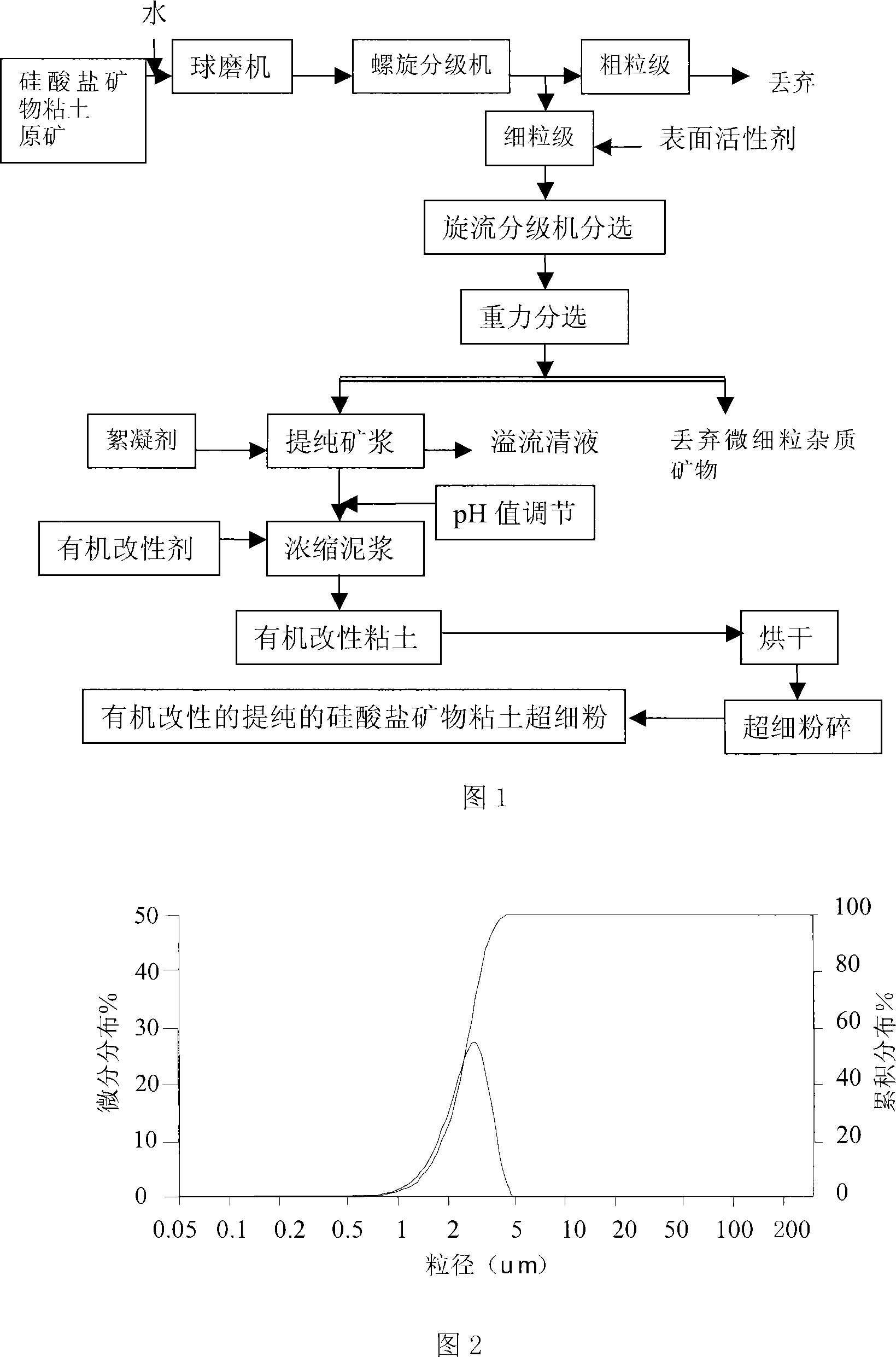

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Organically Modified and Purified Attapulgite

[0043] The first step is primary purification using a spiral classifier

[0044] According to the ratio of adding 4L of water per kg of attapulgite raw ore, the attapulgite raw ore and water are added to the ball mill for grinding, and the formed mud overflows through the spiral classifier to remove impurity minerals with a particle size larger than 0.5mm, and then is sent into the mixing chamber by a mud pump. bucket, add the surfactant sodium polyacrylate and sodium hexametaphosphate at the same time, and stir at a high speed for 30 minutes to obtain highly dispersed primary purified attapulgite slurry. The amount of sodium polyacrylate added is 0.01% of the mass of attapulgite raw ore, The amount of sodium metaphosphate added is 0.1% of the mass of attapulgite raw ore;

[0045] The second step is to use a cyclone classifier for secondary purification

[0046] The highly dispersed and primary purified at...

Embodiment 2

[0060] Preparation of Purified Sepiolite by Organic Modification

[0061] The first step is primary purification using a spiral classifier

[0062] According to the ratio of adding 10L of water per kg of sepiolite raw ore, add sepiolite raw ore and water to the ball mill for grinding, and the formed mud overflows through the spiral classifier to remove impurity minerals with a particle size greater than 0.5mm, and then is sent into the mixing chamber by a mud pump Bucket, add surfactant sodium polyacrylate and sodium hexametaphosphate at the same time, after high-speed stirring for 30 minutes, obtain highly dispersed primary purified sepiolite pulp, the addition of sodium polyacrylate is 0.1% of the mass of sepiolite raw ore, six The addition of sodium metaphosphate is 0.5% of the quality of sepiolite raw ore;

[0063] The second step is to use a cyclone classifier for secondary purification

[0064] The highly dispersed primary purified sepiolite slurry prepared in the firs...

Embodiment 3

[0078] Preparation of Organic Modified Purified Bentonite

[0079] The first step is primary purification using a spiral classifier

[0080] According to the ratio of adding 15L of water per kg of bentonite raw ore, put bentonite raw ore and water into a ball mill for grinding, and the formed mud overflows through a spiral classifier to remove impurity minerals with a particle size greater than 0.5mm, and then is sent into the mixing tank through a mud pump. Surfactant sodium polyacrylate and sodium tripolyphosphate, after stirring at high speed for 30 minutes, obtain highly dispersed primary purified bentonite pulp, the addition of sodium polyacrylate is 2.5% of the mass of bentonite raw ore, and the addition of sodium hexametaphosphate is 2.5% of bentonite 2.5% of the raw ore mass;

[0081] The second step is to use a cyclone classifier for secondary purification

[0082] The highly dispersed primary purified bentonite pulp prepared in the first step is sent into the cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com