Preparation method of water-soluble alcohol-soluble polyurethane

An alcohol-soluble, polyurethane technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as inconvenient use, and achieve the effect of maintaining initial viscosity, high viscosity, and scientific and reasonable production process

Inactive Publication Date: 2010-12-01

ANHUI UNIVERSITY

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to propose a method for preparing alcohol-soluble polyurethane that is easily soluble in water, so as to overcome the inconvenient defect of existing alcohol-soluble polyurethane because it cannot be dissolved in water, and achieve high initial viscosity, fast curing and good stability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

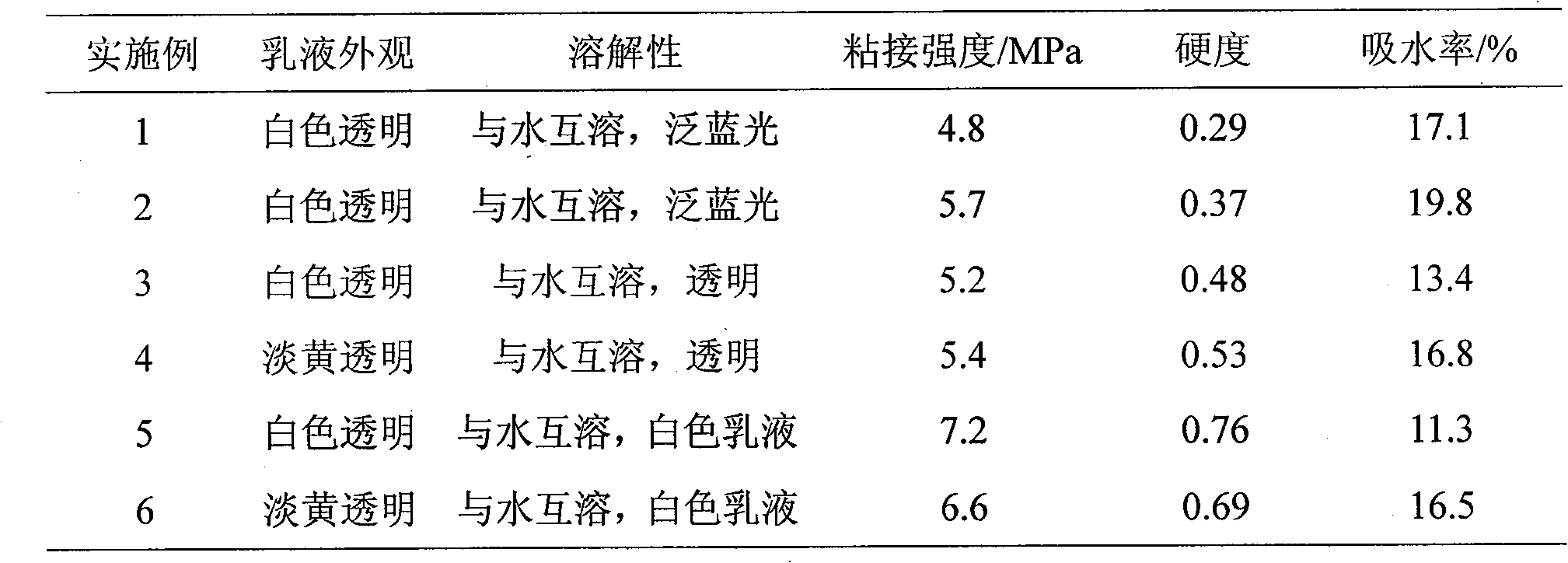

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to water soluble alcohol-soluble polyurethane and a preparation method thereof. The method is characterized in that 5 to 35 percent of oligomer polyhydric alcohol reacts with 5 to 30 percent of polyisocyanate for 2 to 2.5h at 70 to 90 DEG C, 1 to 20 percent of hydrophilic chain-extending agent and 1 to 2 percent of acetone are added, the temperature is maintained at 60 to 70DEG C for 1 to 1.2h, then 2 to 15 percent of chain-extending agent and 0.3 to 0.5 percent of catalyst are added, after reaction is performed at 60 to 70 DEG C for 3 to 4h, the temperature is reduced to 30 to 50 DEG C for discharging, and then a pre-polymer is obtained; after being neutralized with 2 to 5 percent of trihexylamine, the pre-polymer is added into 10 to 70 percent of ethyl alcohol, and an emulsion product can be obtained after emulsification. In the invention, not only superior properties such as high initial viscosity, quick solidification, good stability, etc. of solvent-type polyurethane can be guaranteed, but also the solid content of polyurethane can be adjusted to the actually required value through water, the default of the prior alcohol-soluble polyurethane that the operation is inconvenient because of water insolubility is overcome, thereby the invention can be used in industries such as lumber, flexible package, compound lamination, etc.

Description

A kind of preparation method of water-soluble alcohol-soluble polyurethane Technical field: The invention belongs to the technical field of polyurethane adhesives, and particularly relates to a preparation method of alcohol-soluble polyurethane. Background technique Chinese patent CN02130103.4 discloses a polyurethane resin water dispersion and water-soluble polyurethane adhesive, which utilizes the high bonding strength and good heat resistance and water resistance of polycaprolactone to improve the storage stability and stability of water-soluble polyurethane. However, due to the slow volatilization of water, the water-soluble polyurethane adhesive cannot achieve the performance of solvent-based polyurethane, and it cannot replace the application of solvent-based polyurethane adhesive in some specific occasions. Chinese patent application 200610022515.7 introduces an alcohol-soluble polyurethane two-component adhesive and its preparation process. The main agent and curi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G18/65C08G18/10C09J175/04

Inventor 许戈文谢伟纪学顺张文荣熊潜生

Owner ANHUI UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com