Speed regulating device for double pulse mechanical hydraulic-pressure type diesel engine

A technology of mechanical hydraulic and speed control device, which is applied in the direction of mechanical equipment, machine/engine, engine control, etc., to achieve the effect of stable speed control and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

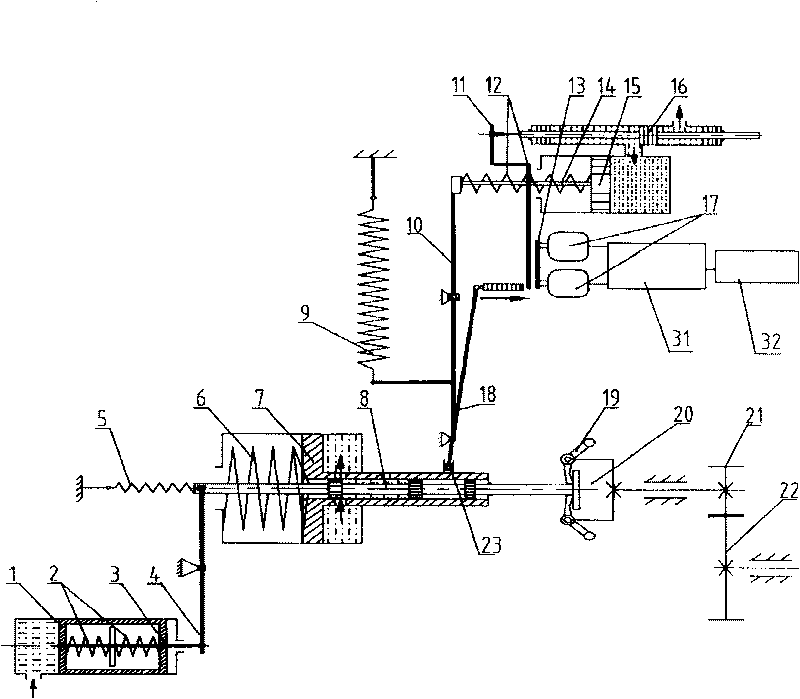

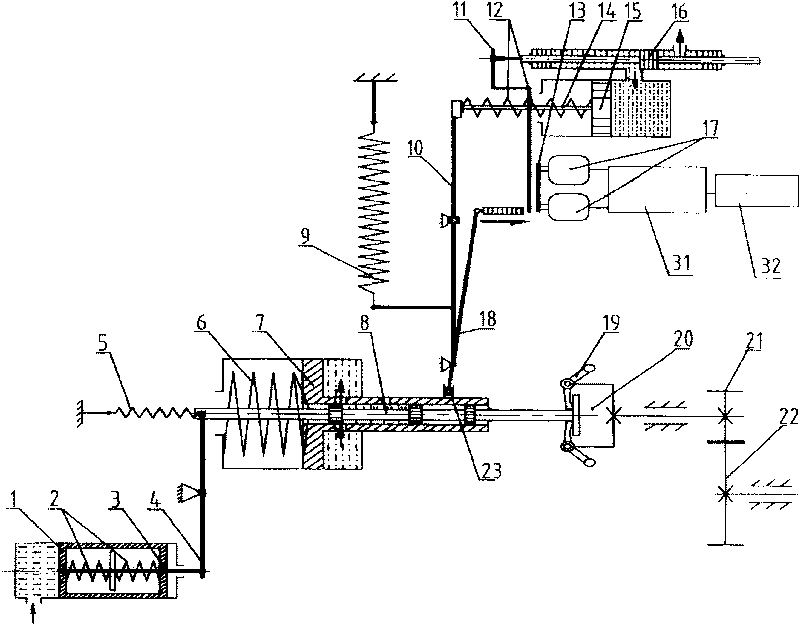

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] combine figure 1 ,exist figure 1 31 is an electronic control module, and 32 is a current sensor. The rotational speed is transmitted to the governor by the elastic gear 22 and the pinion 21 installed on the camshaft of the fuel pump. A hydraulic servo motor piston 7 with a pilot valve 8 is installed in the bore of the housing. The main spring 5 of the speed regulating device is installed on the pilot valve, and the flange of the pilot valve is fixed on the support seat 20 by the lock ring. The flyweight 19 also rests on the support seat 20 . Flyweight 19 and spring 5 are sensitive elements of the speed regulating device. The servo motor of the speed regulating device is made up of piston 7 and bearing spring 6. There are two grooves at the tail end of pilot valve, and the slide block that links to each other with lever 18 is arranged in the groove.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com