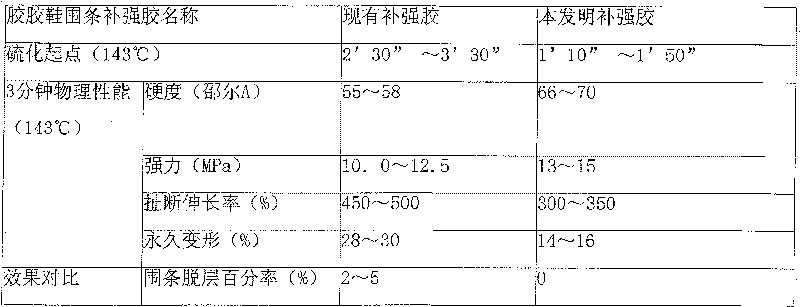

Ultra-low-temperature fast-curing reinforcing glue for rubber shoes and preparation method thereof

A rapid vulcanization, ultra-low temperature technology, applied in applications, shoe uppers, footwear, etc., can solve problems such as delamination of rubber shoe skirts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Raw materials: 2# standard glue 800g, styrene butadiene rubber 200g, sulfur 18g, 16g accelerator M, 18g accelerator DM, 8g accelerator DS, active zinc oxide 20g, stearic acid 16g, softening oil 200g, poly Ethylene glycol 40g, white carbon black 400g, light calcium 480g, calcium base grease 14g, antioxidant KY-405 13g

[0043] Preparation method: (1) Plasticizing: take natural rubber and refine it on an open rubber mixing machine to make the Vickers plasticity reach 0.40~0.45 to obtain a plasticized rubber. The plasticizing condition is: the temperature of the rubber mixing machine roller 40~50℃, the rubber mixer roll distance is below 1mm, the rubber passes through the rubber mixer roll pitch 3 to 4 times, and then the rubber-coated roller is removed from the air bubbles at a roll distance of 9-10 mm;

[0044] (2) Ingredients: mixed plasticized rubber and styrene butadiene rubber to obtain product A, polyethylene glycol, white carbon black, light calcium and calci...

Embodiment 2

[0049] Example 2: Raw materials: 2# standard rubber 800g, styrene butadiene rubber 200g, sulfur 18g, accelerator (M+DM+DS) 42g, active zinc oxide 36g, softening oil 200g, polyethylene glycol 40g and white carbon black 400g

[0050] Preparation method: (1) Mastication: take natural rubber and refine it in an internal mixer to make its Vickers plasticity reach 0.40~0.45 to obtain plastified rubber. The refining conditions are: the internal temperature of the internal mixer is 90~100. ℃, internal mixing chamber pressure 0.2MPa, internal mixer rotor speed 1440rpm, internal mixing secret mixing time 5~5.5min;

[0051] (2) Ingredients: mixing plasticized rubber and styrene butadiene rubber to obtain product A, polyethylene glycol and white carbon black to obtain product B, and mixing accelerator and active zinc oxide to obtain product C;

[0052] (3) Mixing: Put product A into the rubber mixing machine, refining for 0.5 minutes under the conditions of temperature 60~80℃ and pressure 0.35Mp...

Embodiment 3

[0054] Example 3: Raw materials: 2# standard glue 600g, styrene butadiene rubber 150g, sulfur 15g, accelerator (M+DM+DS) 50g, stearic acid 25g, active zinc oxide 5g, softening oil 150g, polyethylene glycol 30g And white carbon black 500g, light calcium 600g, calcium base grease 20g, antioxidant KY-405 15g

[0055] Preparation method: (1) mastication: take natural rubber and refining to make the Vickers plasticity reach 0.40~0.45 to obtain mastication;

[0056] (2) Ingredients: mix plasticized rubber and styrene butadiene rubber to obtain product A, polyethylene glycol, white carbon black, light calcium and calcium-based grease to obtain product B, accelerator (M+DM+DS), active zinc oxide , Stearic acid and anti-aging agent KY-405 are mixed to obtain product C;

[0057] (3) Mixing: Put product A into the rubber mixing machine, refining for 1 minute at a temperature of 100-120°C and a pressure of 0.45Mpa, then add product B and product C to continue refining for 2 minutes, and then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com