Green rubber slurry for rubber shoe wrapping sponge adhesion, preparation method and applications thereof

A rubber pulp and green technology, applied in the direction of natural rubber adhesives, applications, adhesives, etc., can solve problems such as deviation in the positioning and sewing of composite fabrics, affecting the appearance quality of the heel of rubber shoes, wearing comfort and production efficiency, etc. Achieve the effects of improving production efficiency, improving sewing speed and production efficiency, and increasing cross-linking and setting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

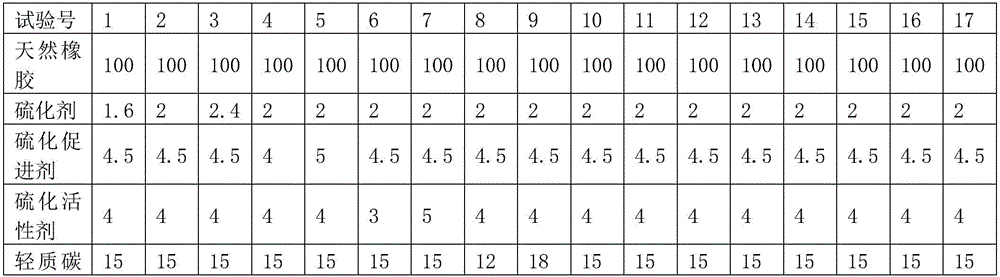

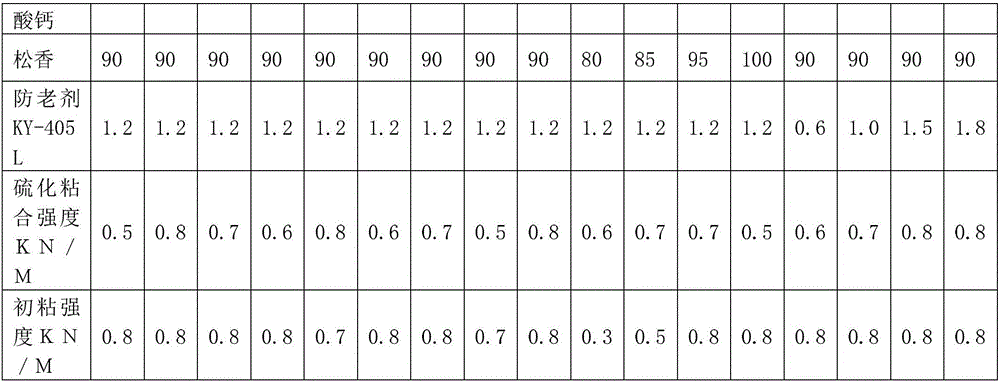

[0051] Embodiment 1 of the present invention: rubber shoe bag sponge is bonded with green rubber pulp, calculates by weight, and it comprises with natural rubber 100 parts, sulfur 2.2 parts, accelerator CBS 0.8 part, accelerator DS 0.7 part, accelerator M 0.5 3.5 parts of zinc carbonate, 1.0 parts of stearic acid, 88 parts of rosin, 15 parts of light calcium carbonate, 1.2 parts of anti-aging agent KY-405L, 88 parts of rosin, 0.3 parts of Y-8804 yellow masterbatch, 0.3 parts of R-8818 red masterbatch 0.05 parts of glue, 0.10 parts of G-2210 green masterbatch and 210 parts of 120# gasoline are the raw materials for preparation.

[0052] The preparation method of green rubber slurry for rubber shoe bag sponge bonding, each component is taken by the above-mentioned parts by weight, comprises the steps:

[0053] 1) Making natural rubber plasticizing rubber: take 15 parts of natural rubber on an open rubber mixing machine, and pass through the machine for 5 times under the conditio...

Embodiment 2

[0060] Embodiment 2 of the present invention: rubber shoe bag sponge is bonded with green rubber pulp, calculates by weight, and it comprises with 100 parts of natural rubber, 1.8 parts of sulfur, 0.8 part of accelerator CBS, 0.7 part of accelerator DS, 0.6 part of accelerator M 3.3 parts of zinc carbonate, 1.2 parts of stearic acid, 90 parts of rosin, 15 parts of light calcium carbonate, 1.5 parts of anti-aging agent KY-405L, 0.3 parts of Y-8804 yellow masterbatch, 0.05 parts of R-8818 red masterbatch, 0.10 parts of G-2210 green masterbatch and 210 parts of 120# gasoline are the raw materials for preparation.

[0061] The preparation method and use are the same as in Example 1.

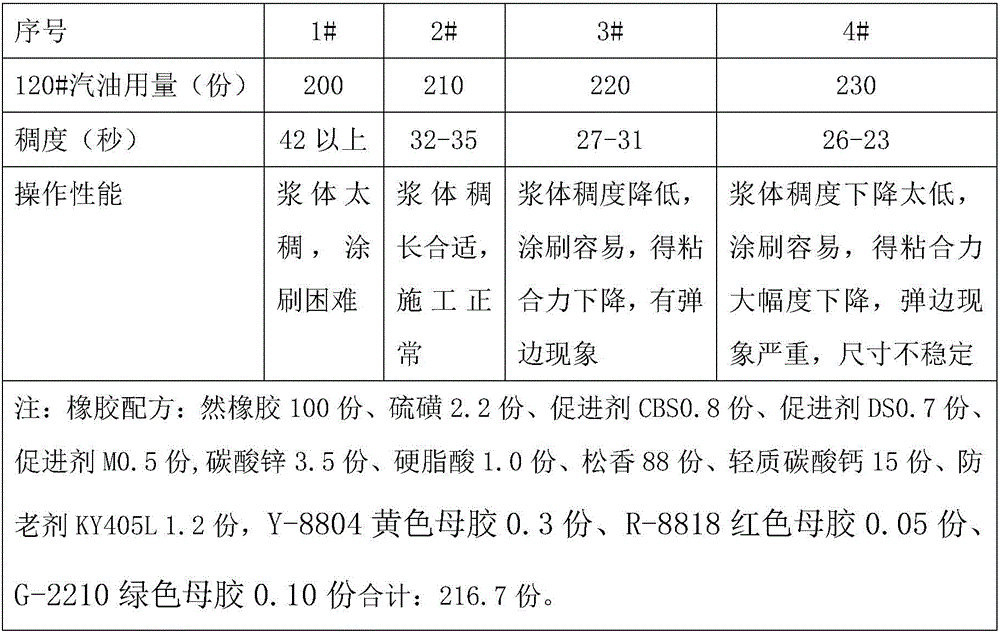

[0062] The comparative data of the adhesive mortar process of the present invention and the existing non-adhesive sewing process:

[0063]

[0064] The comparison in the above table proves that the production efficiency and product quality of the rubber shoe sponge sewing process have been greatl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com