Mold for sewing back waist band

A belt and mold technology, applied in the field of sewing, can solve the problems of reduced work efficiency, inaccurate sewing, unfavorable operation of employees, etc., and achieve the effect of improving work efficiency, improving sewing speed, and high sewing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

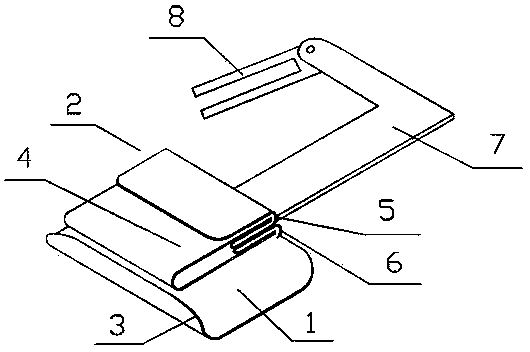

[0017] A mold for a waist belt after sewing, comprising a first guide and a second guide 2; the first guide includes a bottom plate 1, and the left side of the bottom plate 1 is provided with a half U-shaped hook 3 with an opening facing right; the second guide 2 includes: a bracket 4, the upper and lower sides of the bracket 4 are respectively provided with an upper U-shaped hook 5 with an opening facing left and a lower U-shaped hook 6 with an opening facing left, and the lower half of the U-shaped hook 6 is fixed on the bottom plate 1 on;

[0018] The bracket 4 is a U-shaped plate with an opening facing the right;

[0019] The bottom plate 1 of the first guide is also connected with a fixing part 7;

[0020] The fixing part 7 is L-shaped, and the outer end of the L shape is hinged with the socket fixing part 8;

[0021] The first guide piece and the second guide piece 2 are made of copper alloy.

[0022] When the present invention is in use, the two layers of cloth that ...

Embodiment 2

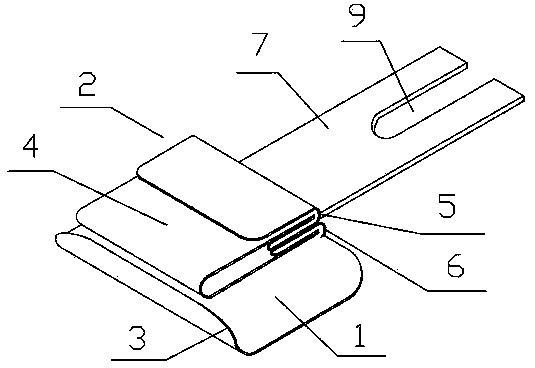

[0024] A mold for a waist belt after sewing, comprising a first guide and a second guide 2; the first guide includes a bottom plate 1, and the left side of the bottom plate 1 is provided with a half U-shaped hook 3 with an opening facing right; the second guide 2 includes: a bracket 4, the upper and lower sides of the bracket 4 are respectively provided with an upper U-shaped hook 5 with an opening facing left and a lower U-shaped hook 6 with an opening facing left, and the lower half of the U-shaped hook 6 is fixed on the bottom plate 1 on;

[0025] The bracket 4 is a U-shaped plate with an opening facing the right;

[0026] The bottom plate 1 of the first guide is also connected with a fixing part 7;

[0027] The fixing part 7 is rectangular, and one end of the fixing part 7 is provided with a mounting hole 9; through the mounting hole, the fixing part can be fixed on the bottom plate of the sewing machine with screws, and other usage methods are the same as in the first em...

Embodiment 3

[0030] A mold for a waist belt after sewing, comprising a first guide and a second guide 2; the first guide includes a bottom plate 1, and the left side of the bottom plate 1 is provided with a half U-shaped hook 3 with an opening facing right; the second guide 2 includes: a bracket 4, the upper and lower sides of the bracket 4 are respectively provided with an upper U-shaped hook 5 with an opening facing left and a lower U-shaped hook 6 with an opening facing left, and the lower half of the U-shaped hook 6 is fixed on the bottom plate 1 on;

[0031] The first guide piece and the second guide piece 2 are made of copper alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com