Wide strip edge pressing tool

A technology of edge pressing and tooling, which is applied in the direction of textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., to achieve the effect of solving side yarn detachment, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

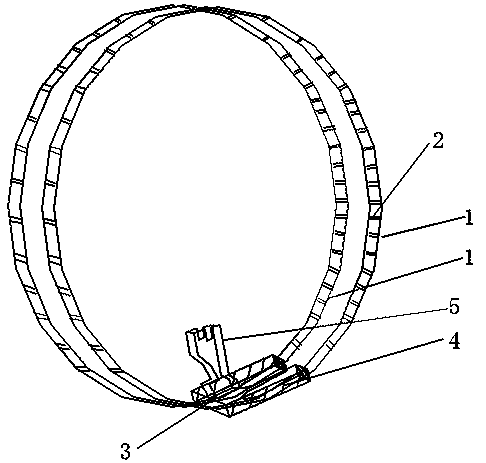

[0017] as attached figure 1 As shown, the wide-strip edge-holding tooling of this embodiment includes two juxtaposed ring-shaped bead 1, the inner surface of the ring-shaped bead 1 is provided with chain teeth 2, and the juxtaposed ring-shaped bead 1 is provided with a bead fixing frame 3 , the bead fixing frame 3 includes a U-shaped splint 4, the U-shaped splint 4 is set on the juxtaposed annular bead 2, and the upper end of the U-shaped splint 4 is connected with a handle 5.

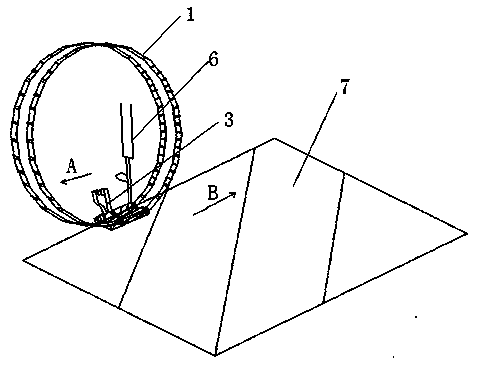

[0018] as attached figure 2 As shown, when sewing flanging or hemming sewing, the annular bead 1 is pressed on both sides of the selvage 7 at the same time, and the U-shaped splint 4 is opened toward the position where the front edge of the sewing machine plate is relatively closest to the sewing needle 6, and the sewing needle 6 Through the gap between the two side-by-side annular bead 1, the selvedge 7 is sewn from back to front, and the worker applies pressure to the bead fixing frame 3, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com