Direct acting capacitive transducer and method for producing same

A transducer, capacitive technology, applied in the field of direct-acting capacitive transducers and their manufacturing, can solve the problems of winding number limitation, long response time of the driver, etc., to reduce the noise level, reduce the manufacturing cost, and reduce the wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

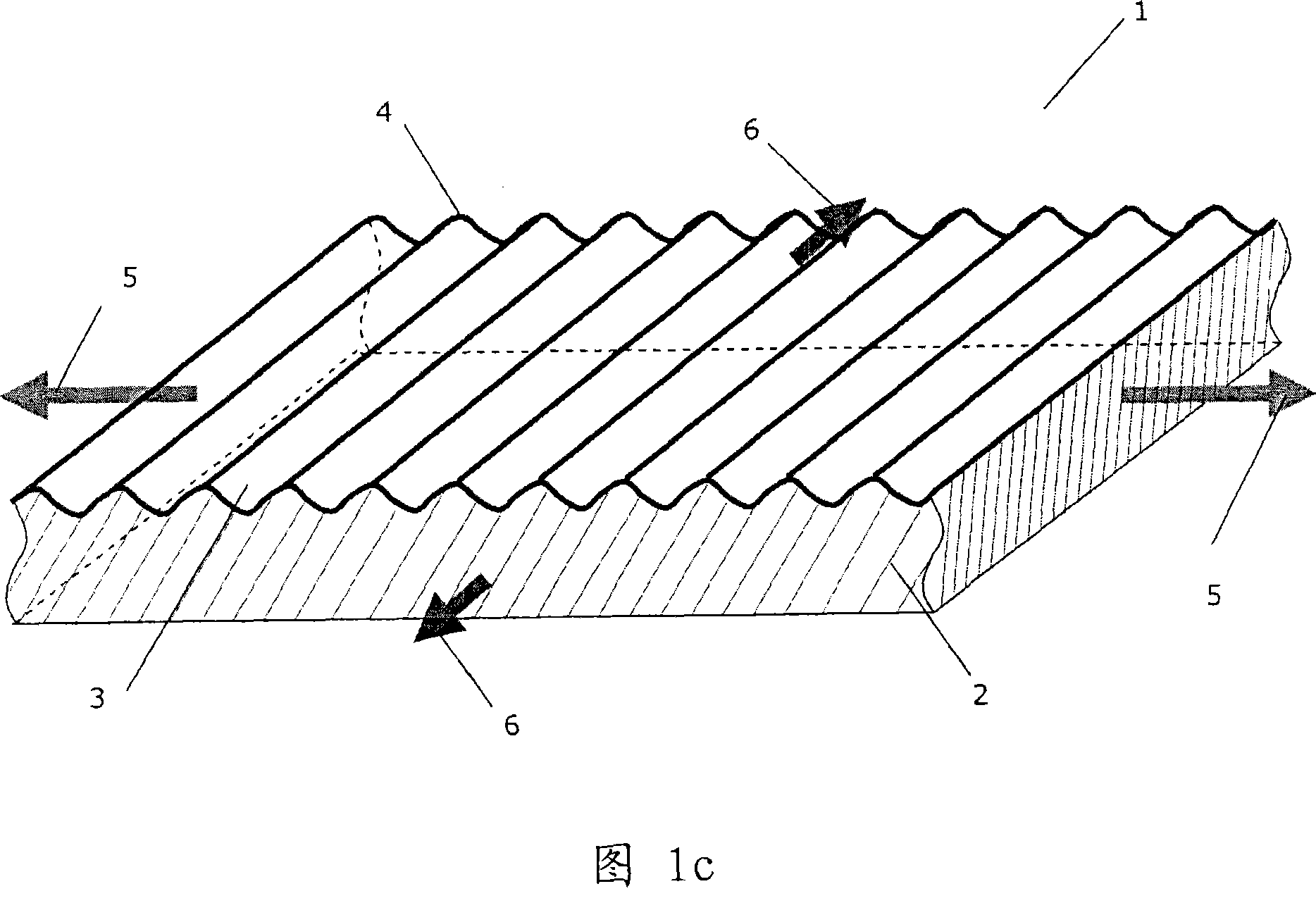

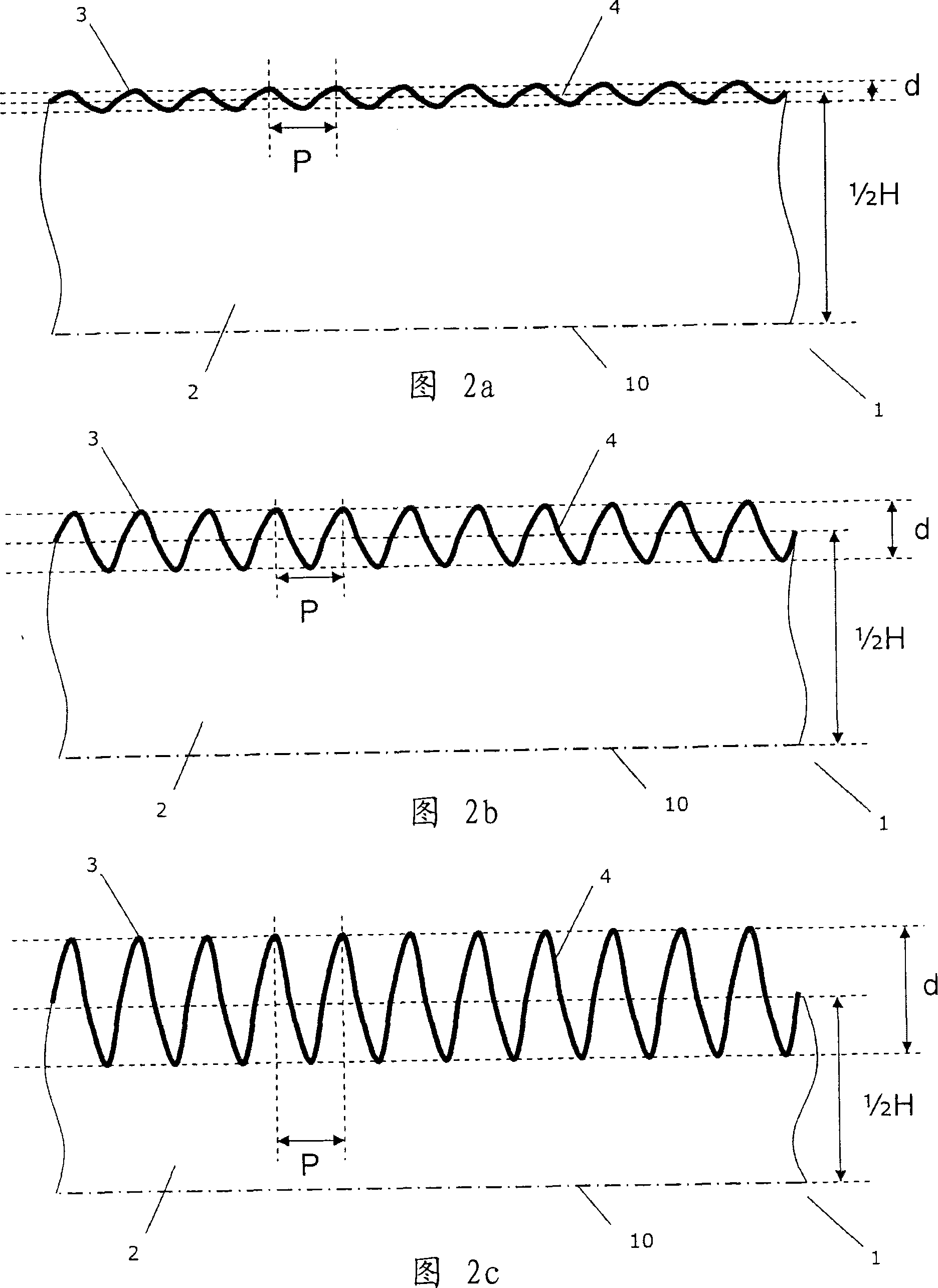

[0145] Figure 1a and 1b shows a continuous roll of composite 1 of a reel according to an embodiment of the invention, and Figure 1c Perspective view of part of Complex 1. The scale of the composite is distorted to show the different elements of composite 1. The composite 1 comprises a film 2 made of a dielectric material having a surface 3 provided with a pattern of raised and recessed surface portions, whereby a designed corrugated profile of the surface 3 is formed. A conductive layer 4 has been applied to the surface 3, a conductive material being deposited such that the conductive layer is formed according to a pattern of raised and recessed surface portions. As far as everyday objects are concerned, film 2 is similar in some respects to household packaging films. It has a similar thickness and is relatively soft. However, it is more elastic than this membrane, with a pronounced mechanical anisotropy, as will be described below.

[0146] The dielectric material may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com