Vertical Bridgman growth furnace and method of optimizing temperature field inside furnace

A vertical Bridgeman, growth furnace technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc. To solve the problem of component supercooling, increase the axial temperature gradient, and achieve the effect of small fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

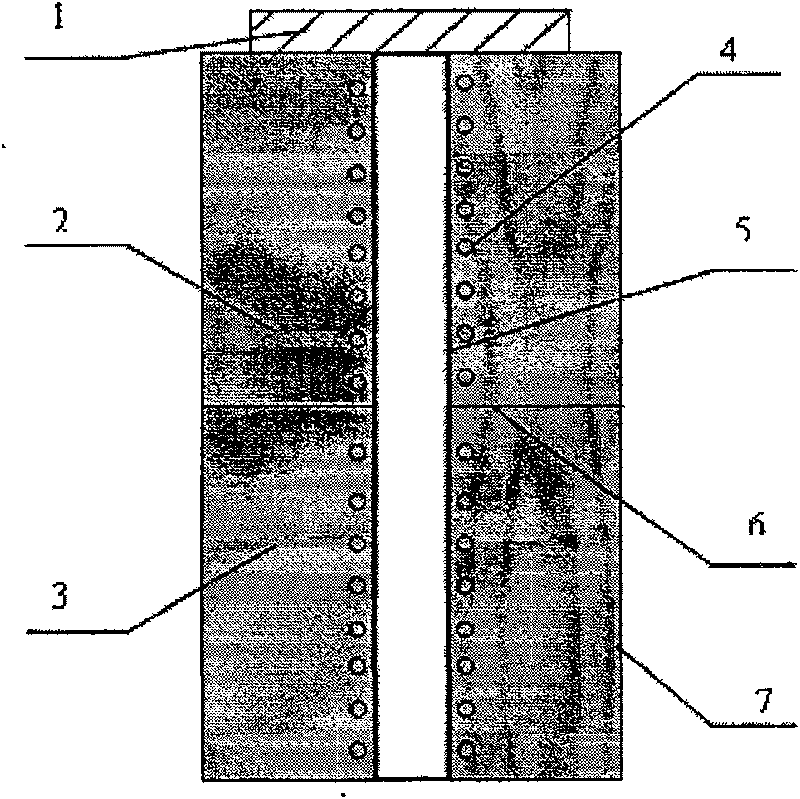

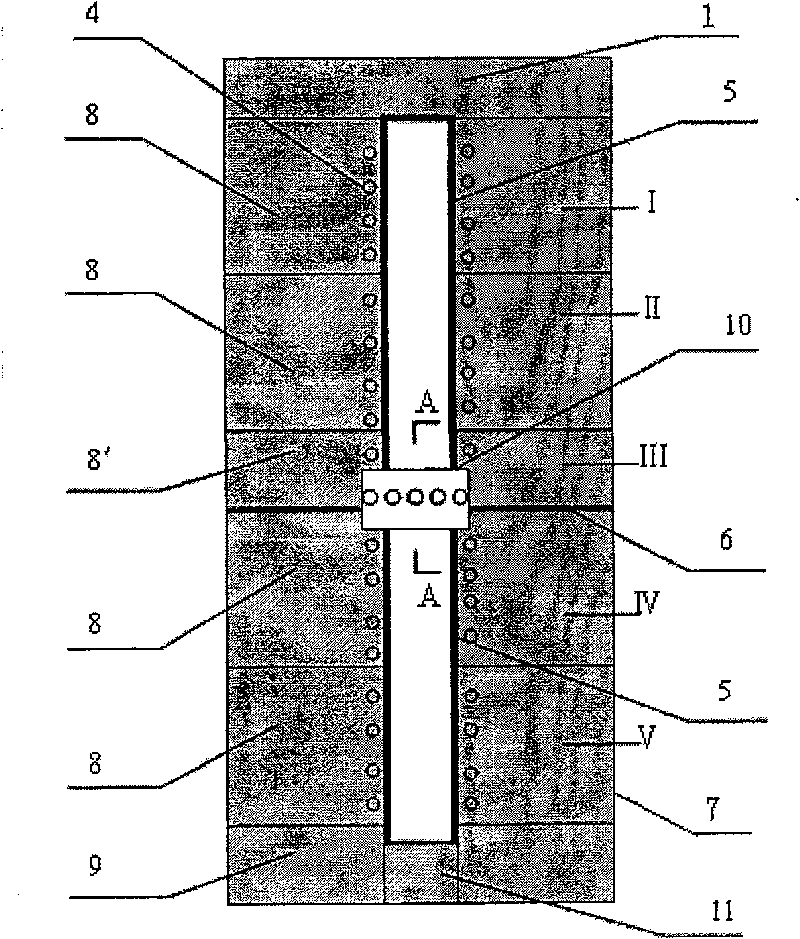

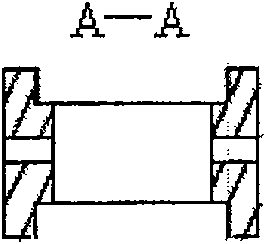

Embodiment 1

[0016] Embodiment 1: refer to figure 2 The vertical Bridgman growth furnace of the present invention includes a furnace cover 1, a heating wire 4, a liner 5, a cooling fin 6, and a casing 7, and also includes a type I heating module 8, a type II heating module 8', and a heat shield 9 , bushing 10 and refractory ceramic wool 11. In the shell 7, from bottom to top, there are heat insulation boards 9, two sets of I-type heating modules 8, heat sinks 6, one set of II-type heating modules 8', two sets of I-type heating modules 8, and furnace cover 1, heat insulation boards The center hole of 9 is refractory ceramic wool 11, and the central position of the five-section heating module is two sections of liner 5, the lower end of the lower section of liner 5 is flush with the heat shield 9, the upper end of the upper section of liner 5 is flush with the furnace cover 1, and the two The section liner 5 is separated by cooling fins 6, and there is a liner 10 outside the joint of the l...

Embodiment 2

[0017] Embodiment 2: Designing a suitable five-section modular tube resistance furnace to grow Cd 0.9 Zn 0.1 Te boule.

[0018] First place a heat shield 9 with an outer diameter of 450mm and a central aperture of 120mm and a height of 150mm at the lowermost end of the shell 1. During crystal growth, refractory ceramic wool 11 is used to seal the central aperture to prevent the flow of atmosphere from affecting the temperature field. Place two I-type heating modules 8 with an outer diameter of 450mm and a central aperture of 120mm and a height of 220mm on it, and then symmetrically place three fan-shaped superalloy heat sinks with a thickness of 3mm, and place a high-temperature alloy tube with an inner diameter of 90mm, a wall thickness of 3mm, and a length of 450mm The liner 5 is placed at the center hole of the module, and an alumina ceramic bushing 11 with an inner diameter of 90 mm, a wall thickness of 5 mm, and a height of 60 mm is placed on it as a thermal insulation ...

Embodiment 3

[0022] Example 3: Growth of Cd using a five-section modular tubular resistance furnace 0.8 mn 0.2 Te boule.

[0023] First, a heat shield 9 with an outer diameter of 400 mm and a central aperture of 90 mm and a height of 150 mm is placed at the lowermost end of the shell 1. During crystal growth, refractory ceramic wool 11 is used to seal the central hole to prevent the flow of the atmosphere from affecting the temperature field. Place two I-type heating modules 8 with an outer diameter of 400 mm and a central aperture of 90 mm and a height of 200 mm on it, and then symmetrically place four fan-shaped high-temperature alloy heat sinks with a thickness of 3 mm, and place a high-temperature alloy tube with an inner diameter of 70 mm, a wall thickness of 3 mm, and a length of 400 mm. The liner 5 is placed at the central hole of the module, and an alumina ceramic bushing 11 with an inner diameter of 70 mm, a wall thickness of 5 mm, and a height of 70 mm is placed on it as a therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com