Chemical plating reinforcing method and apparatus for airborne tank internal surface protection

An electroless plating, inner surface technology, applied in liquid electroless plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

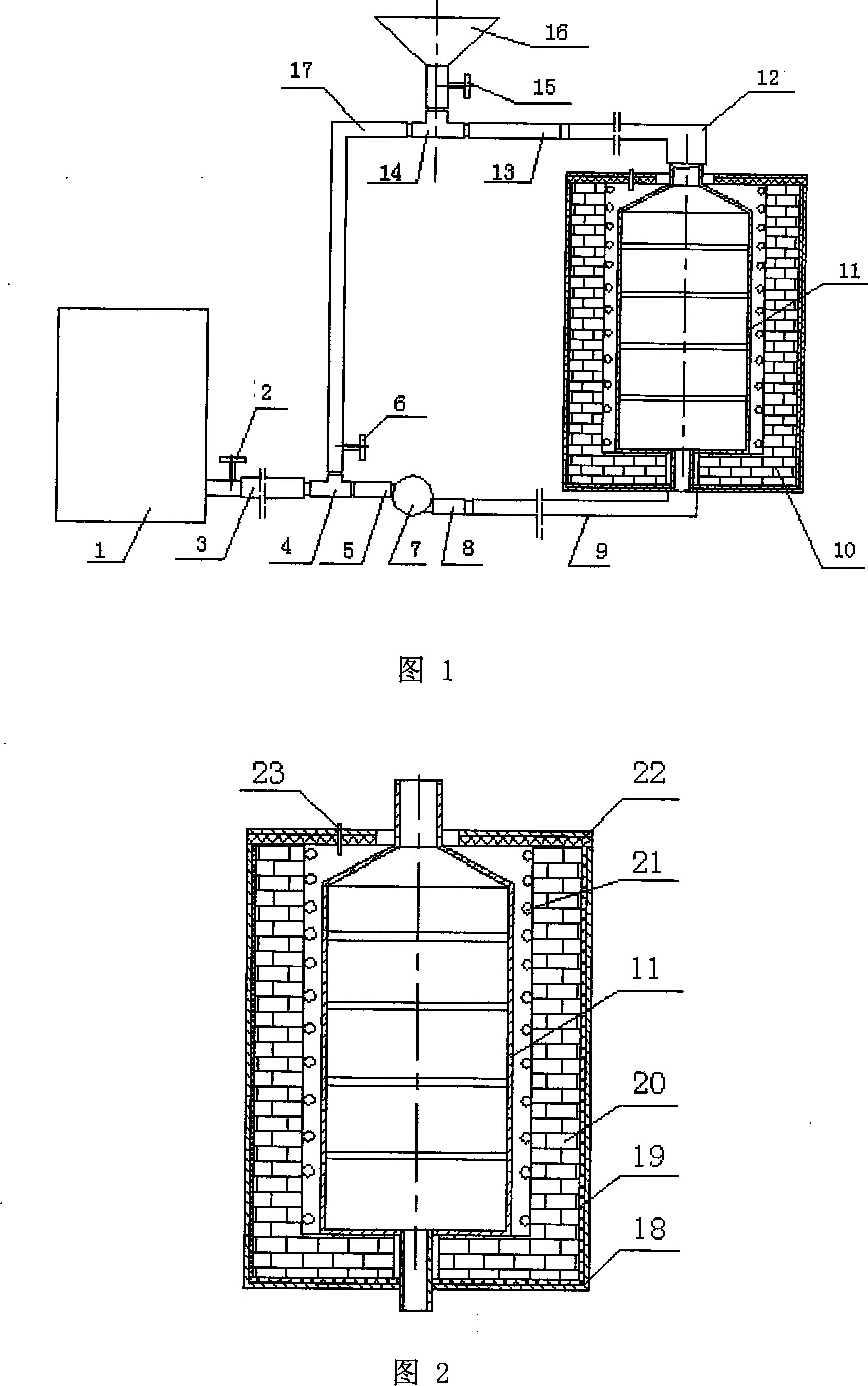

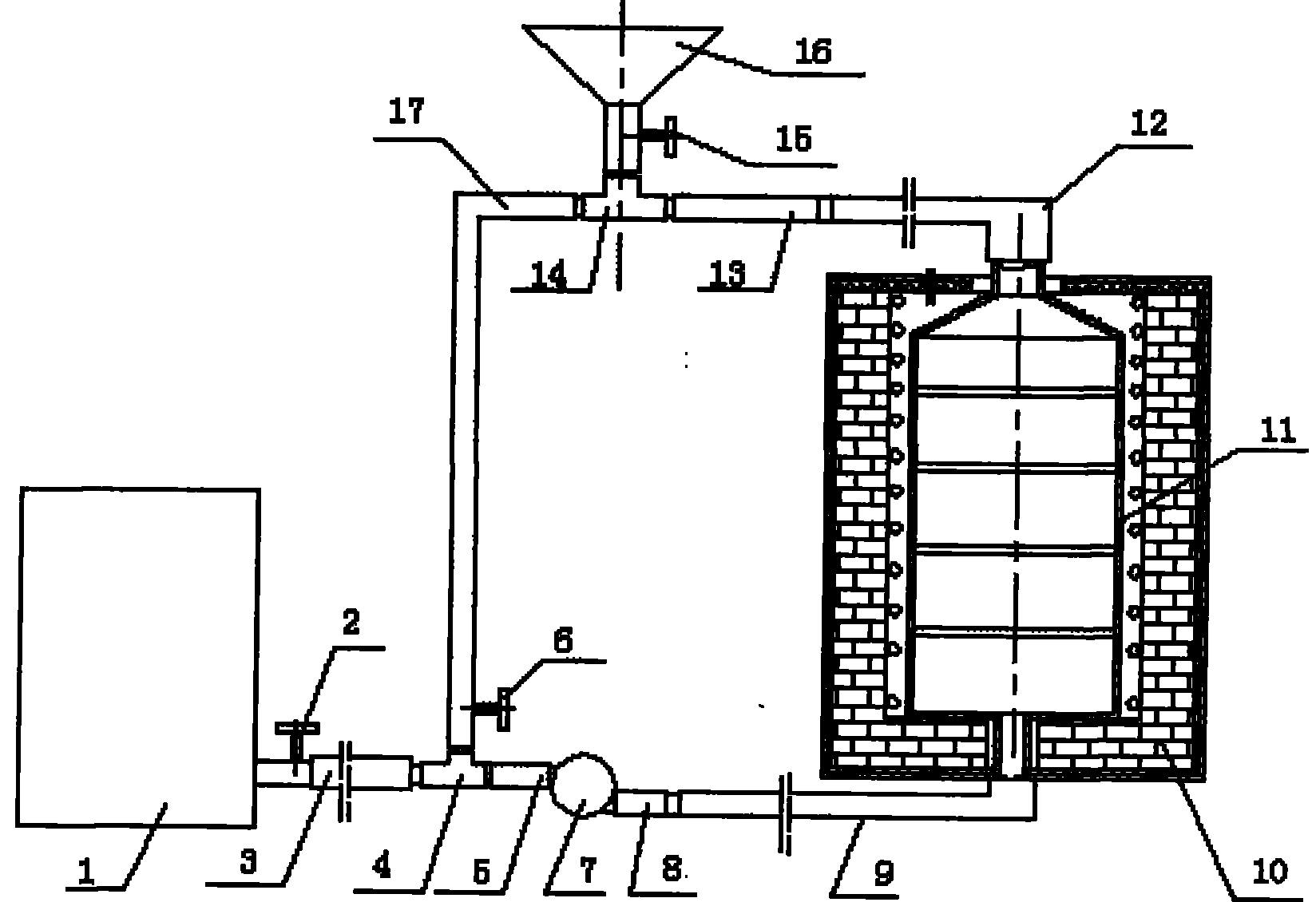

[0032] As shown in Figure 1, it is an electroless plating strengthening device. One end of the hose one 3 is connected to the discharge pipe of the liquid storage tank 1. There is a valve one 2 on the discharge pipe of the liquid storage tank 1 to control the opening and closing of the liquid; the hose one The other end of 3 is connected with one end of the three-way pipe-4; the second end of the three-way pipe-4 is connected with one end of the compound pipe-5, and the other end of the compound pipe-5 is connected with one end of the suction pump 7 , the other end of the suction pump 7 is connected with one end of the flexible pipe 9 through the composite pipe 2 8, and the other end of the flexible pipe 9 is connected with the bottom pipeline of the on-board fuel tank 11; the top pipeline of the on-board fuel tank 11 passes through a flexible Pipe three 12 is connected with one end of composite pipe three 13, the other end of composite pipe three 13 is connected with one end o...

Embodiment 2

[0045] Under the situation that other operation is constant, the embodiment that changes relevant process parameter is as follows:

[0046] (1) Chemical degreasing and derusting, the processing time is 8 minutes since the degreasing and derusting solution fills the on-board oil tank; the formula of chemical degreasing and derusting is: hydrochloric acid: 400ml / L, hexamethylenetetraammonium: 5g / L, OP-10 emulsifier: 12g / L, water: balance;

[0047] (2) For the first water washing, the processing time is 8 minutes since the water fills the on-board fuel tank;

[0048] (3) Nickel-phosphorus electroless plating, the treatment temperature of nickel-phosphorus electroless plating is 80°C, and the plating time is 1 hour since the nickel-phosphorus electroless plating solution fills the on-board fuel tank and the temperature reaches 80°C; the nickel-phosphorus electroless plating formula is : Nickel sulfate: 18g / L, sodium hypophosphite: 20g / L, citric acid: 8g / L, lactic acid: 18-22ml / L...

Embodiment 3

[0053] (1) Chemical degreasing and rust removal, the treatment time is 10 minutes from the time when the degreasing and derusting liquid is filled with the on-board oil tank; the formula of chemical degreasing and derusting is: hydrochloric acid: 300ml / L, hexamethylenetetraammonia: 4g / L, OP-10 emulsifier: 1.5g / L, water: balance;

[0054] (2) For the first water washing, the treatment time is 10 minutes from the time when the on-board fuel tank is filled with water;

[0055] (3) Nickel-phosphorus electroless plating, the treatment temperature of nickel-phosphorus electroless plating is 90°C, and the plating time is 1 hour since the nickel-phosphorus electroless plating solution fills the on-board fuel tank and the temperature reaches 90°C; the nickel-phosphorus electroless plating formula is : Nickel sulfate: 122g / L, sodium hypophosphite: 25g / L, citric acid: 12g / L, lactic acid: 22ml / L, ammonium acetate: 122g / L, Pb 2+ : 0.25mg / L, pH value: 5.0;

[0056] (4) Nickel-phosphorus-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com