Screw spike anchoring agent

A technology of spiral spikes and anchoring agents, applied in the field of anchoring materials, can solve problems such as volume shrinkage, sleeper damage, excessive temperature difference of sleepers, etc., and achieve the effects of improved durability, extended service life, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

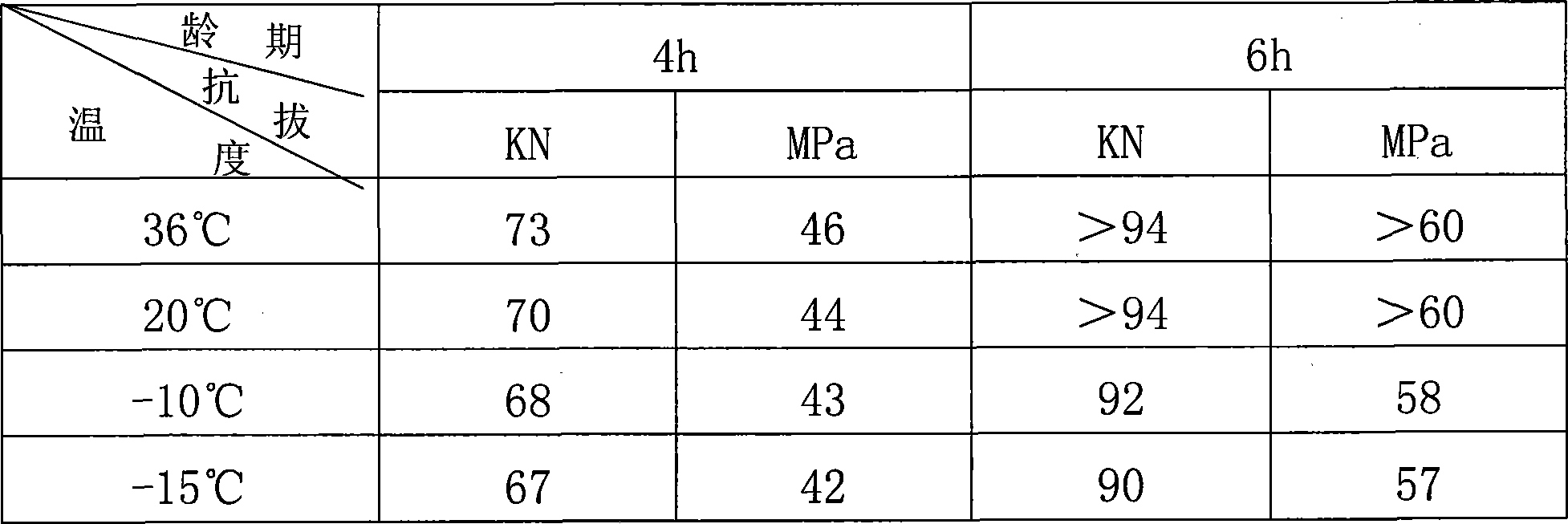

Image

Examples

Embodiment 1

[0023] Embodiment 1, spiral road stud anchoring agent, the weight proportion (by weight) of each component is: the Portland cement 30kg that label is 32.5, the sand 20kg that particle diameter is below 2mm, tertiary fly ash 30kg, Weifang Dayuan Industrial Co., Ltd. produces 20kg of polymer concrete waterproofing agent with a concentration of 9mol / L, which is mixed to form a fluid spiral spike anchoring agent.

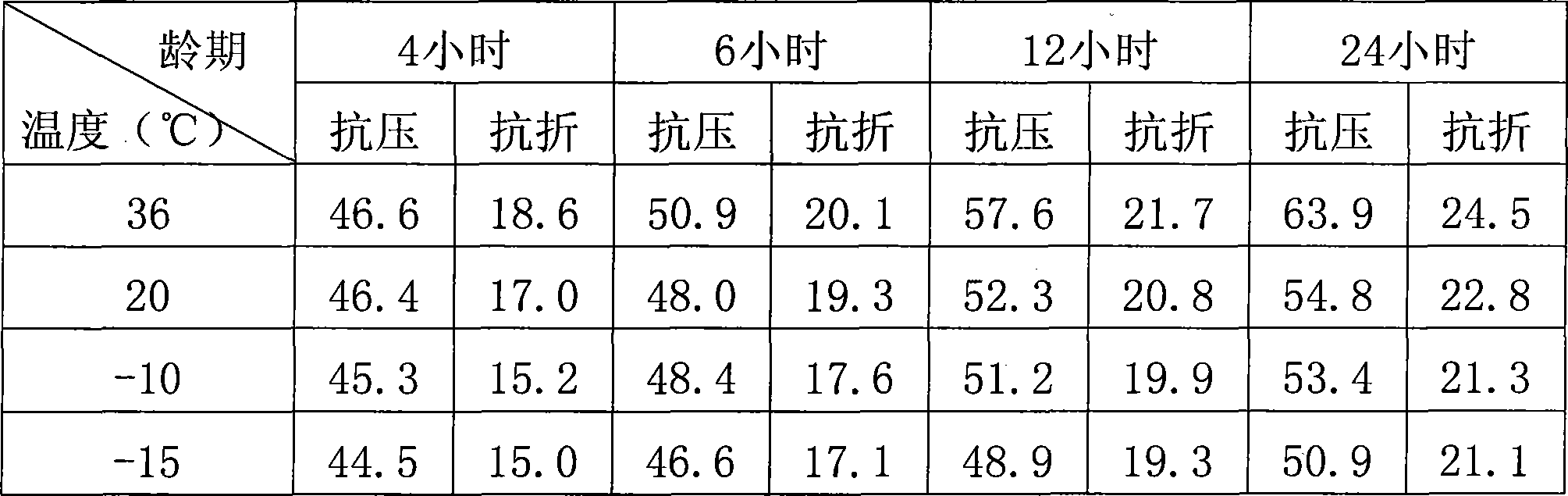

[0024] The following table is the compressive and flexural strength data (MPa) obtained by the test of the road stud anchoring agent in this embodiment under different temperature conditions:

[0025]

[0026] The following table is the test result of the loss of dynamic modulus of the road stud anchoring agent before and after the freeze-thaw cycle in this embodiment:

[0027] Dynamic modulus before freeze-thaw cycles

Modulus of elasticity after freeze-thaw cycles

Specimen parameters

number

width

100mm

Specimen ...

Embodiment 2

[0044] Embodiment 2, spiral road stud anchoring agent, the weight proportion (by weight) of each component is: the portland cement 25kg that label is 32.5, the sand 25kg that particle diameter is 0.5mm~3mm, secondary fly ash 30kg, 20kg of polymer concrete waterproofing agent with a concentration of 9mol / L produced by Weifang Dayuan Industrial Co., Ltd., after mixing to form a fluid spiral spike anchoring agent.

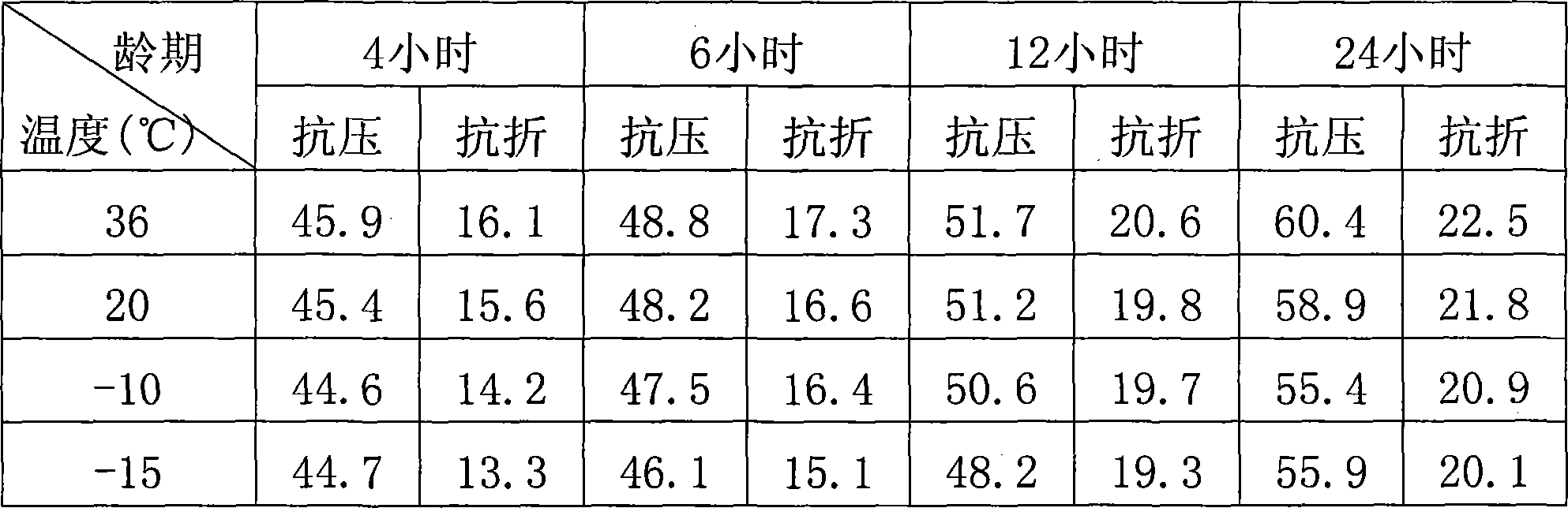

[0045] The following table shows the compressive and flexural strength data (MPa) of the road stud anchoring agent in the above embodiment under different temperature conditions:

[0046]

[0047] The following table is the test results of the loss of dynamic modulus of the road stud anchoring agent before and after the freeze-thaw cycle of the above embodiment:

[0048] Dynamic modulus before freeze-thaw cycles

Modulus of elasticity after freeze-thaw cycles

Specimen

parameter

width

100mm

Specimen

parame...

Embodiment 3

[0064] Embodiment 3, spiral road stud anchoring agent, the weight ratio (by weight) of each component is: 30kg of Portland cement with a label of 42.5, 20kg of sand with a particle size below 1.25mm, and 30kg of first-grade fly ash 1. Weifang Dayuan Industrial Co., Ltd. produces 20kg of polymer concrete waterproofing agent mixing solution with a concentration of 9mol / L, which forms a fluid spiral spike anchoring agent after mixing.

[0065] The following table shows the compressive and flexural strength data (MPa) of the road stud anchoring agent in the above embodiment under different temperature conditions:

[0066]

[0067] The following table is the test results of the loss of dynamic modulus of the road stud anchoring agent before and after the freeze-thaw cycle of the above embodiment:

[0068] Dynamic modulus before freeze-thaw cycles

Modulus of elasticity after freeze-thaw cycles

Specimen

parameter

width

100mm

Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com