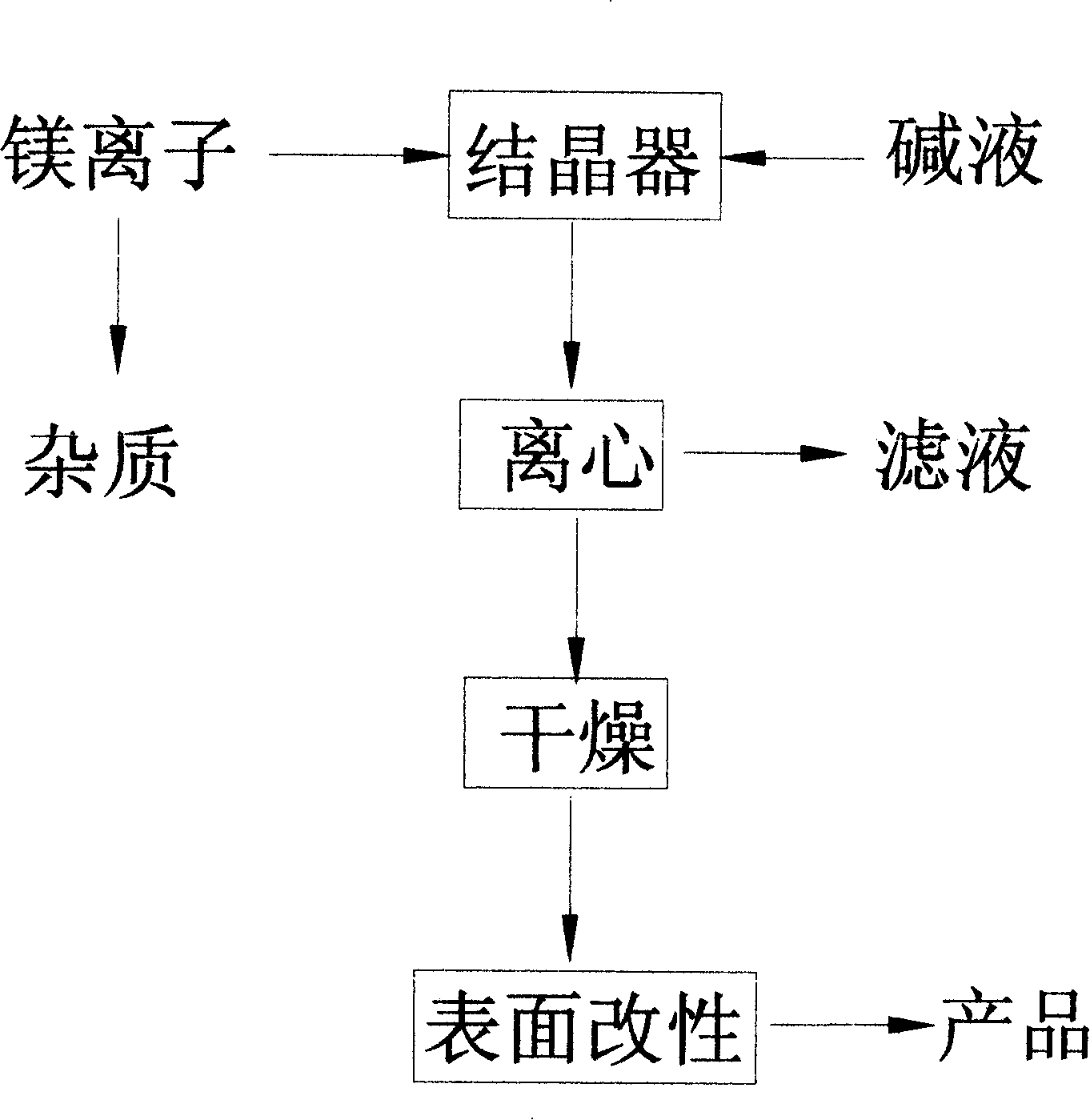

Process for producing nano-flame-proof magnesium hydroxide

A magnesium hydroxide and nano-flame retardant technology, applied in the direction of magnesium hydroxide, etc., can solve the problems of difficult control of crystal particle size and low purity, and achieve the effect of mild reaction conditions and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First, dissolve 51 grams of bischofite with deionized water, add water to about 1 liter, and remove insoluble impurities by suction filtration. Dissolve 20 grams of sodium hydroxide in a 1-liter beaker at room temperature; then use a metering pump to inject the two reaction solutions into the impingement flow reactor, control the impact flow rate at 100ml / min, and the residence time in the reactor for 30 min; finally after washing, filtering, and drying at 120°C to obtain magnesium hydroxide. Its purity is 99.4%, the average particle size is 13.5nm, and TEM analysis shows that it is flaky crystal.

Embodiment 2

[0021] Dissolve 20.3 grams of bischofite with deionized water, add water to about 1 liter, and remove insoluble impurities by suction filtration. Dissolve 10 grams of sodium hydroxide in a 1-liter beaker at a temperature of 40°C; use a metering pump to inject the two reaction solutions into the impingement flow reactor, and control the impact flow rate at 50ml / min. The residence time is 30min; finally, it is washed, filtered, and dried at 120°C to obtain magnesium hydroxide. Its purity is 98%, the average particle size is 19.8nm, and TEM analysis shows that it is flaky crystal.

Embodiment 3

[0023] Dissolve 20.3 grams of bischofite with deionized water, add water to about 1 liter, and remove insoluble impurities by suction filtration. Dissolve 10 grams of sodium hydroxide in a 1-liter beaker at a temperature of 60°C; use a metering pump to inject the two reaction solutions into the impingement flow reactor, and control the impact flow rate at 100ml / min. The residence time is 30min; finally, it is washed, filtered, and dried at 120°C to obtain magnesium hydroxide. Its purity is 98.9%, the average particle size is 17.6nm, and TEM analysis shows that it is needle-like crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com