An electric spindle design adopting electromagnetism anti-thrusting and air static pressure radial bearing support

A technology of thrust bearings and radial bearings, applied in the field of machinery, can solve problems such as rotor creep, high bearing height, and excessive vibration of the electric spindle shaft system, and achieve the effects of simple processing technology, high dynamic balance precision, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

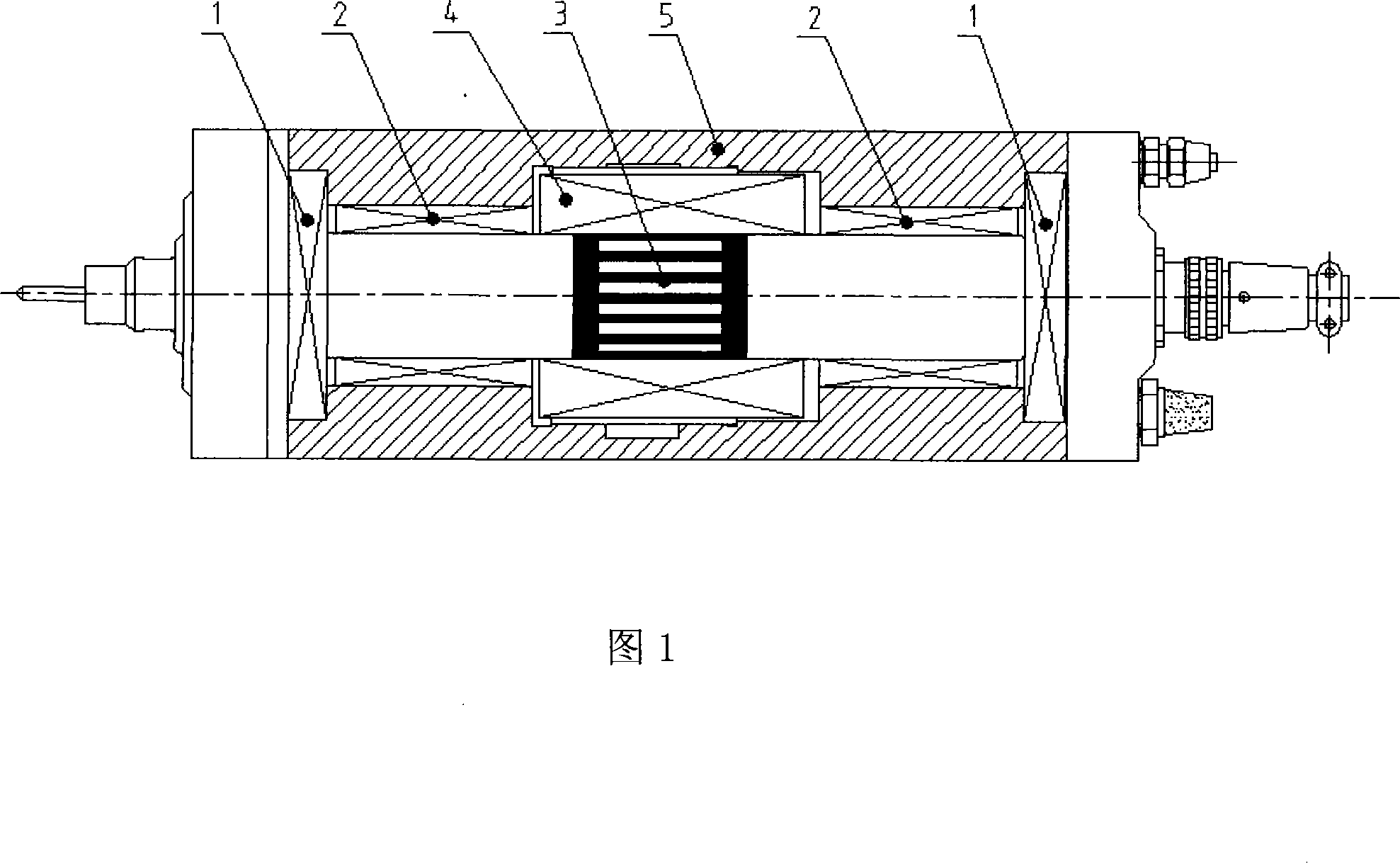

[0015] As shown in Figure 1, the design of the electric spindle adopting electromagnetic thrust and pneumatic radial bearing support of the present invention, according to the external dimension limitation and rigidity requirements of the electric spindle, electromagnetic stoppers are arranged at both ends of the electric spindle housing (5). Push bearings (1), the configuration of both ends can eliminate the electromagnetic interference between the two electromagnetic thrust bearings (1), and is also conducive to the design and concentration of power supply lines for the electromagnetic thrust bearings (1), ensuring the rotor-shaft integrated shafting (3) axial rigidity; aerostatic radial bearings (2) are symmetrically arranged on both sides of the electric spindle housing (5) to support the rotor-rotating shaft integrated shafting (3), and the symmetrically arranged aerostatic radial bearings (2) The radial bearing (2) can reduce the vibration of the rotor-rotating shaft inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com