Multi-test point semiconductor test machine station automated setting method

A technology of testing machine and setting method, applied in semiconductor/solid-state device testing/measurement, digital circuit testing, electronic circuit testing, etc. problems, to reduce risks and losses, reduce test costs, and improve detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the preferred embodiments given in conjunction with the accompanying drawings.

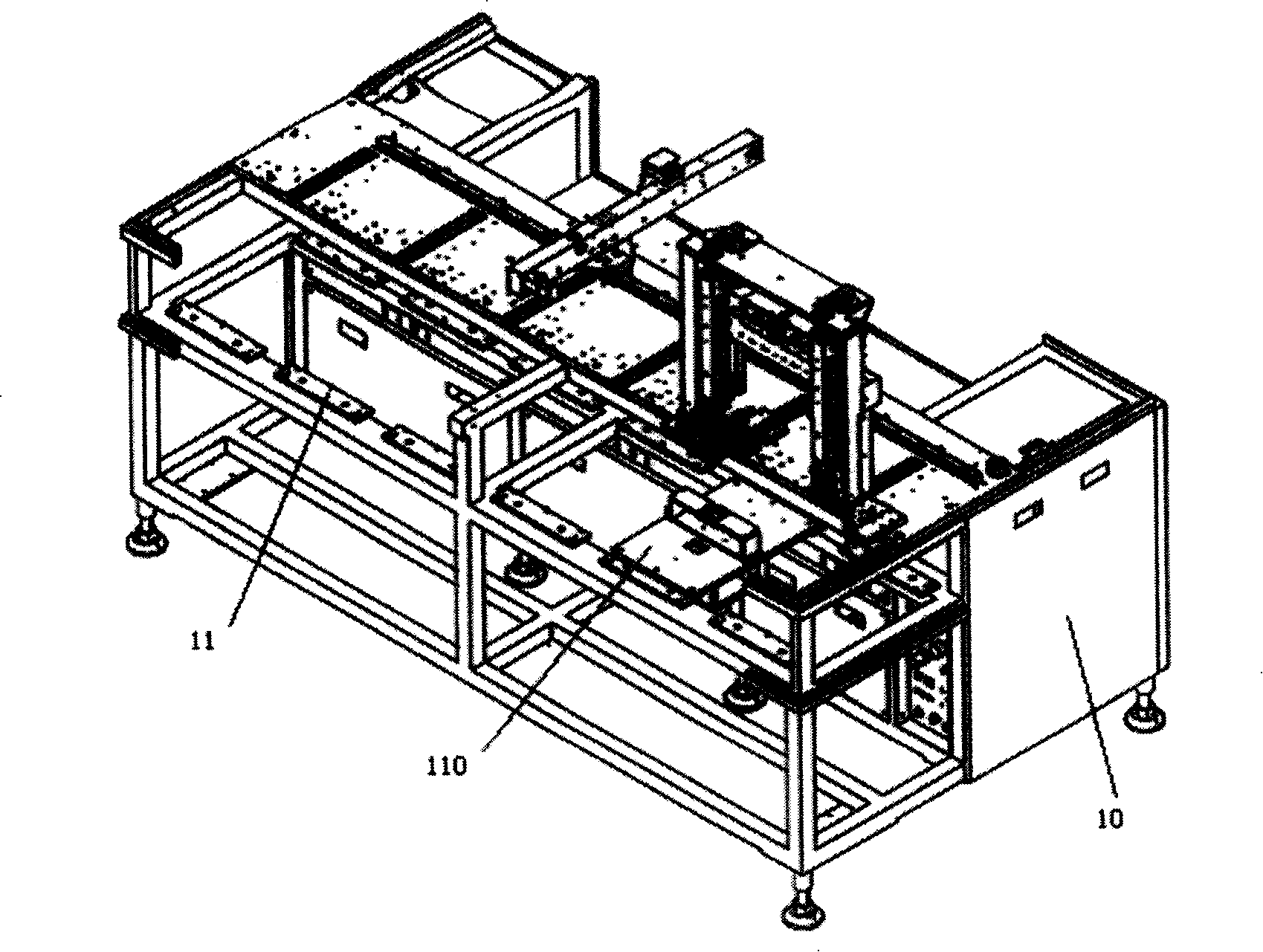

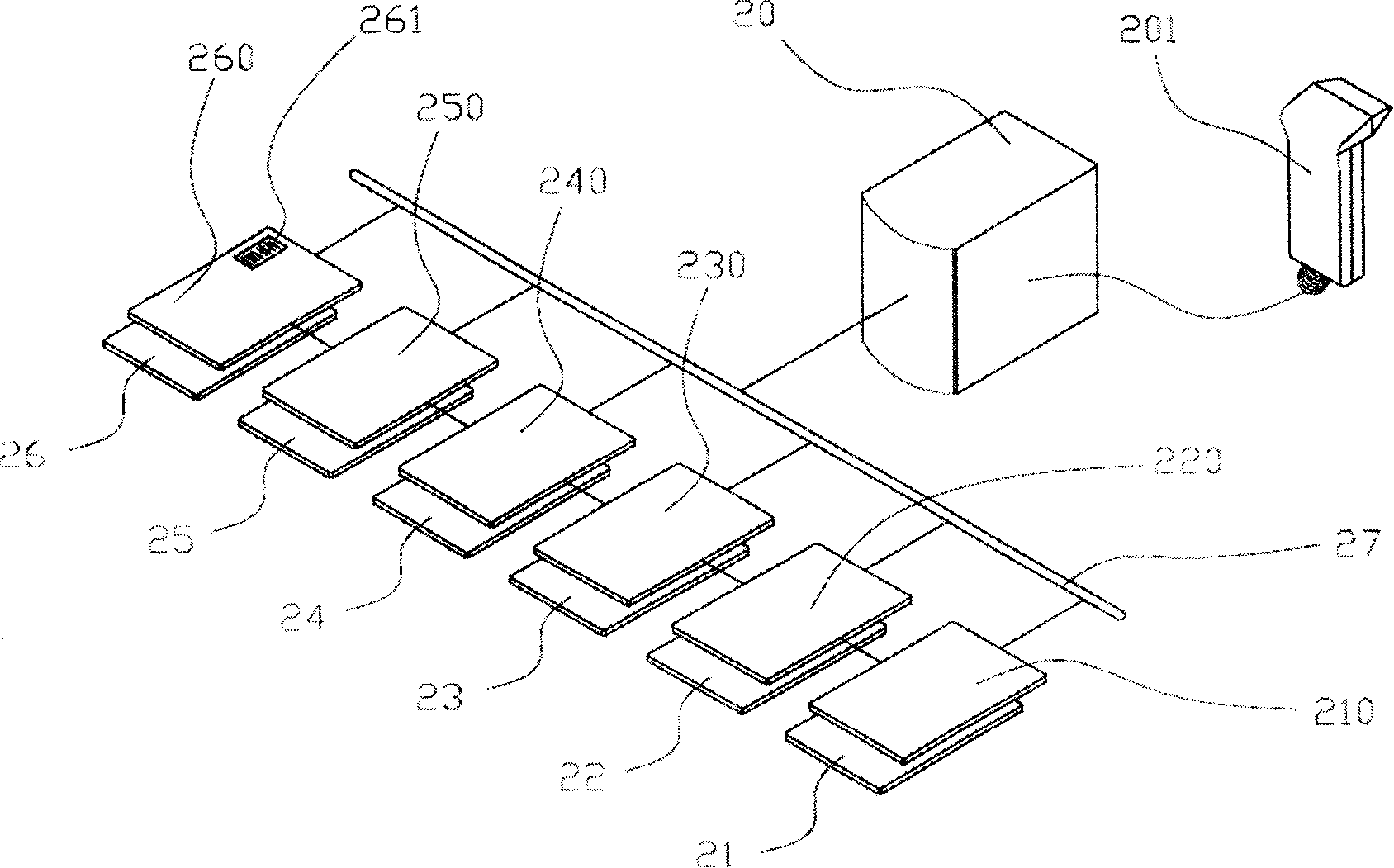

[0034] see figure 2 , as a preferred embodiment of the automatic setting method of the multi-test port semiconductor test machine of the present invention, the test machine includes a control device 20, a bar code reading device 201, six test bases 21-26, and Six test circuit boards 210-260 respectively arranged on the test bases 21-26, and each test circuit board has an identification code; wherein, the control device 20 is connected to the test bases 21-26 via the internal LAN 27 The test circuit boards 210-260 of the control device 20 are also provided with an identification code obtaining device.

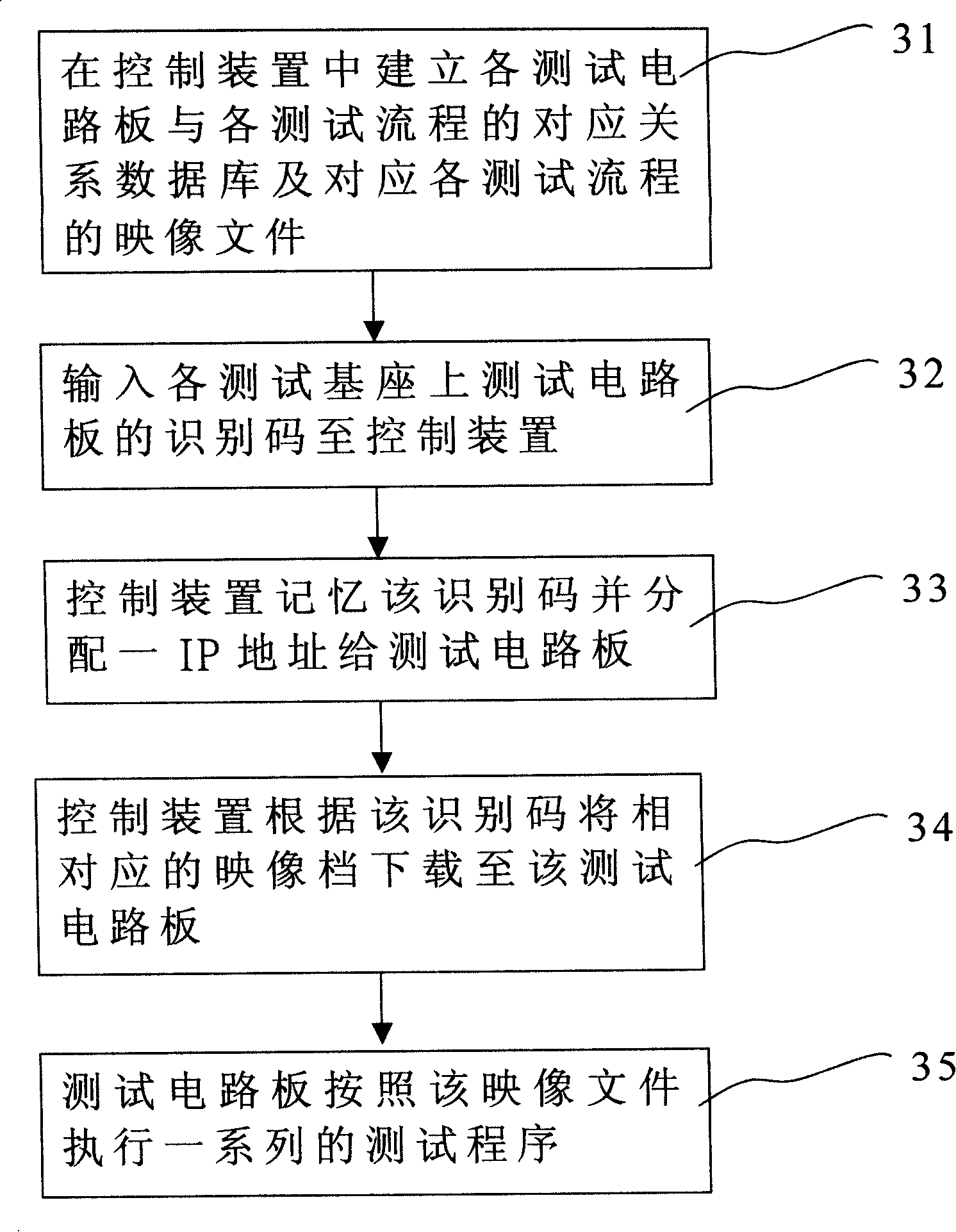

[0035] Such as image 3 As shown, before the test machine actually starts to operate, firstly, in the machine building step 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com