Carbon modified material for lithium ion secondary battery negative pole and preparation thereof

A technology for secondary batteries and modified materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle stability, many uncertain factors, and difficulty in mass production, to improve processing performance, eliminate air Sensitive, process-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

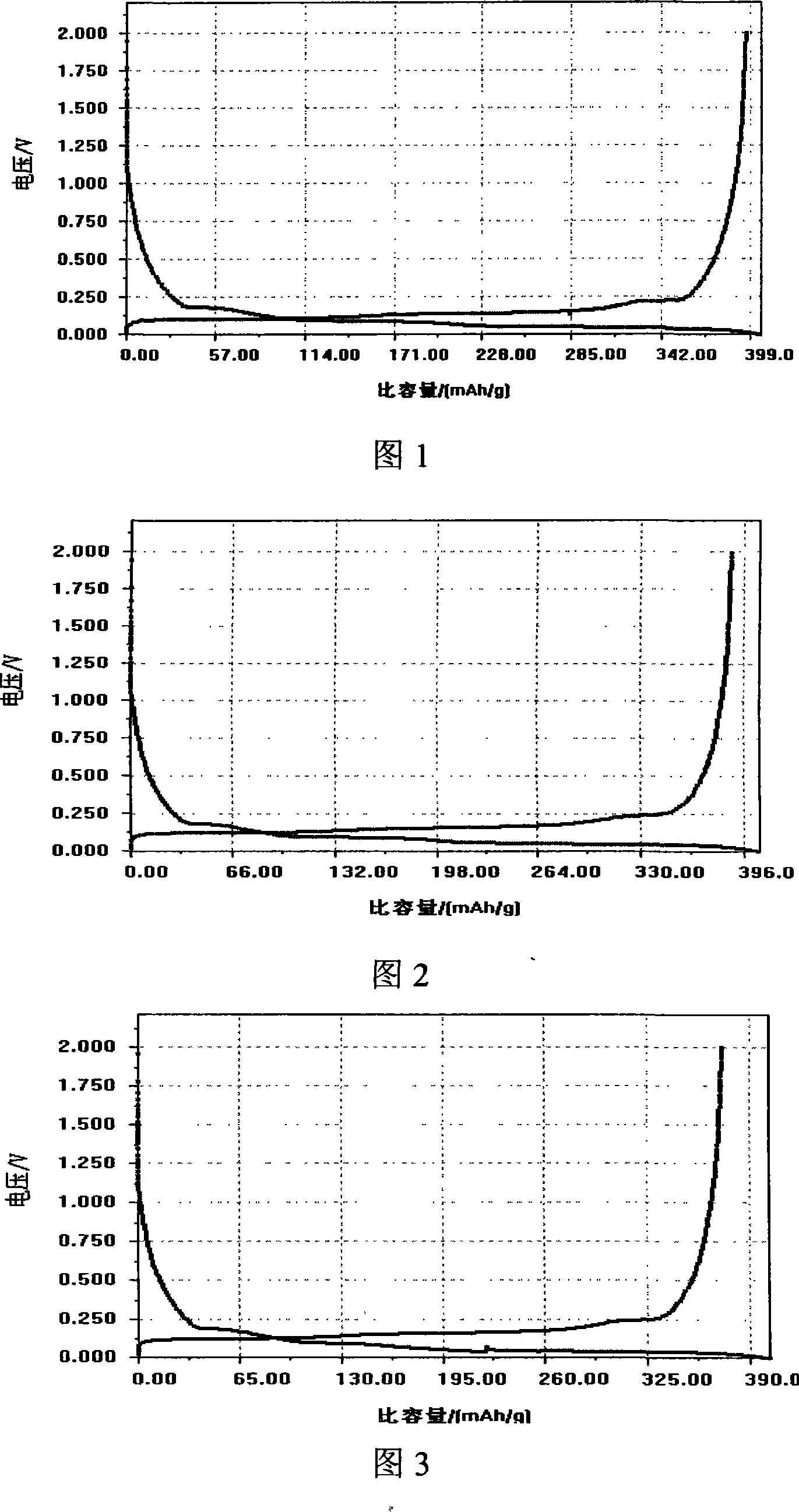

Embodiment 1

[0031] Take by weighing 150 grams of glucose and pour it into a clean beaker of 500 milliliters, then add 300 grams of solvent carbon disulfide, fully stir for 2 hours under the mixer, and adjust the rotating speed to 1000 rpm to make it fully dissolve to form a homogeneous dispersion system; Add 20 grams of 50% styrene-butadiene rubber and 3 grams of 3% span80 to the dispersion system for activation, continue to stir for 1 hour, then place it in a 1-liter pressure vessel with a stirrer, start stirring while heating, the stirring speed The temperature was raised to 350°C at a rate of 10°C / min at 500 rpm, held for 12 hours, then taken out and cooled to room temperature, then dispersed and passed through a 325-mesh sieve to obtain a precursor.

[0032] Then take 100 grams of precursor and 10 grams of petroleum pitch with a softening point of 200°C and a median diameter of 3um for mixing. After mixing evenly, take it out and put it into a graphite crucible for medium-temperature h...

Embodiment 2

[0036] Take by weighing 120 grams of fructose and put it in a clean beaker of 500 milliliters, then add 250 grams of solvent carbon disulfide to form a homogeneous dispersion system; add 30 grams of 50% styrene-butadiene rubber and 5 grams of 3% span80 in the homogeneous dispersion system Activation is performed to obtain a precursor.

[0037] Then take 100 grams of precursor and 12 grams of coal tar pitch with a softening point of 220 °C for mixing coating modification.

[0038] Other parts of this embodiment are identical to Embodiment 1.

[0039] The first discharge capacity of the material is 384.7mAh / g, and the first charge and discharge efficiency is 93.9%.

Embodiment 3

[0041] Weigh 100 grams of glucose and 80 grams of fructose and put them in a 500-ml clean beaker, then add 320 grams of solvent xylene, stir fully under the mixer for 2 hours, and adjust the speed to 1200 rpm to fully dissolve and form a homogeneous dispersion System; add 35 grams of 50% styrene-butadiene rubber and 4 grams of 3% span80 into the homogeneous dispersion system to activate the precursor.

[0042] Then take 100 grams of precursor and 15 grams of coal tar pitch with a softening point of 240°C and a median diameter of 3um for mixing and coating modification. The medium-temperature heat treatment time is 12 hours, followed by high-temperature treatment at 2800°C for 24 hours.

[0043] Other parts of this embodiment are identical to Embodiment 1.

[0044] It was detected that the first discharge capacity of the material was 398.9mAh / g, and the first charge and discharge efficiency was 94.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com