Dynamic control type electronic equipment dissipating heat method and system

A technology of electronic equipment and heat dissipation method, which is applied in the field of dynamic control electronic equipment heat dissipation method and system, can solve the problems of internal circuit burning of blade servers, excessive time and energy, and inconsistency with human resource application cost and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

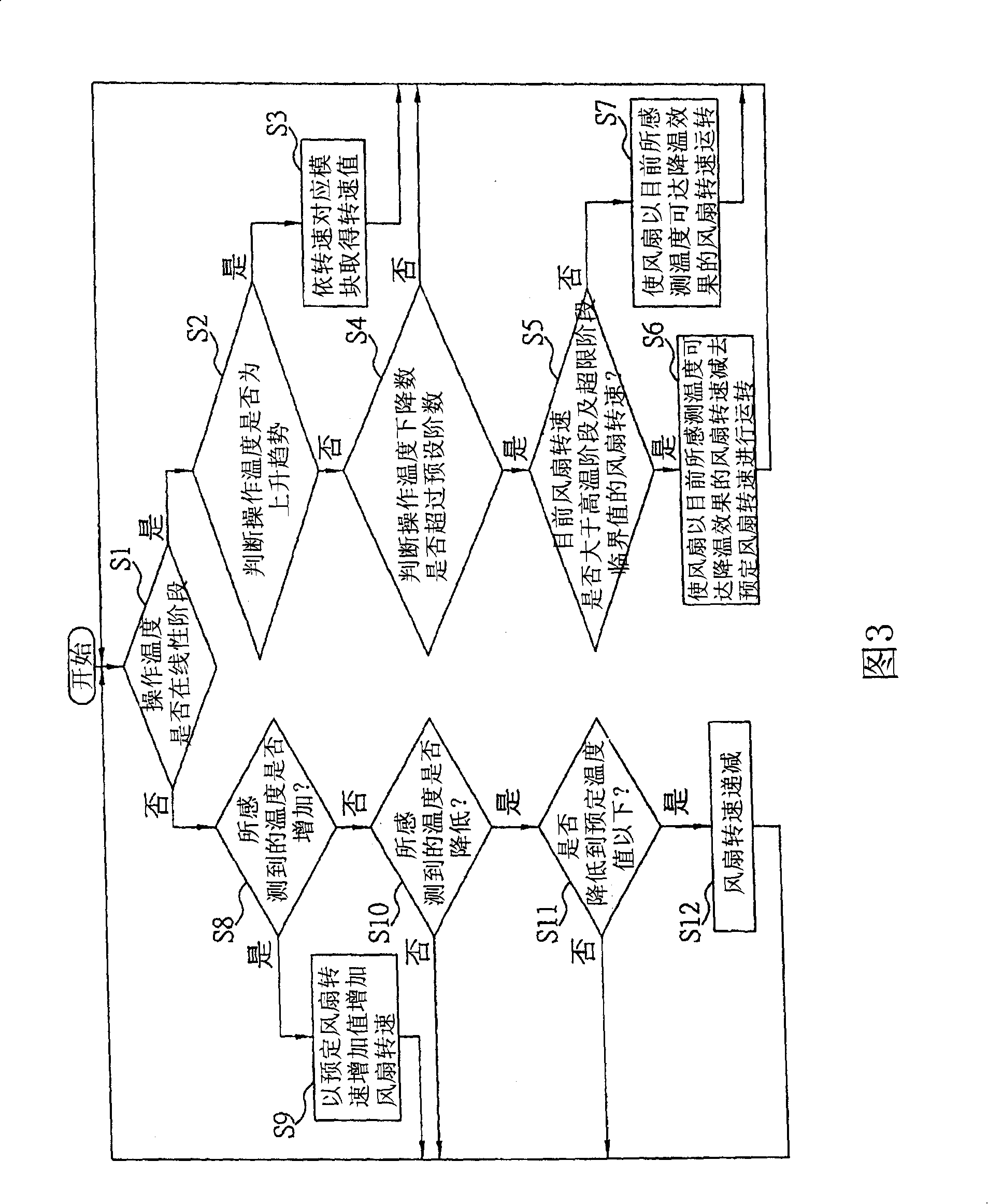

[0023] The following describes in detail the embodiments of the dynamic control electronic equipment heat dissipation method and system of the present invention in conjunction with the accompanying drawings.

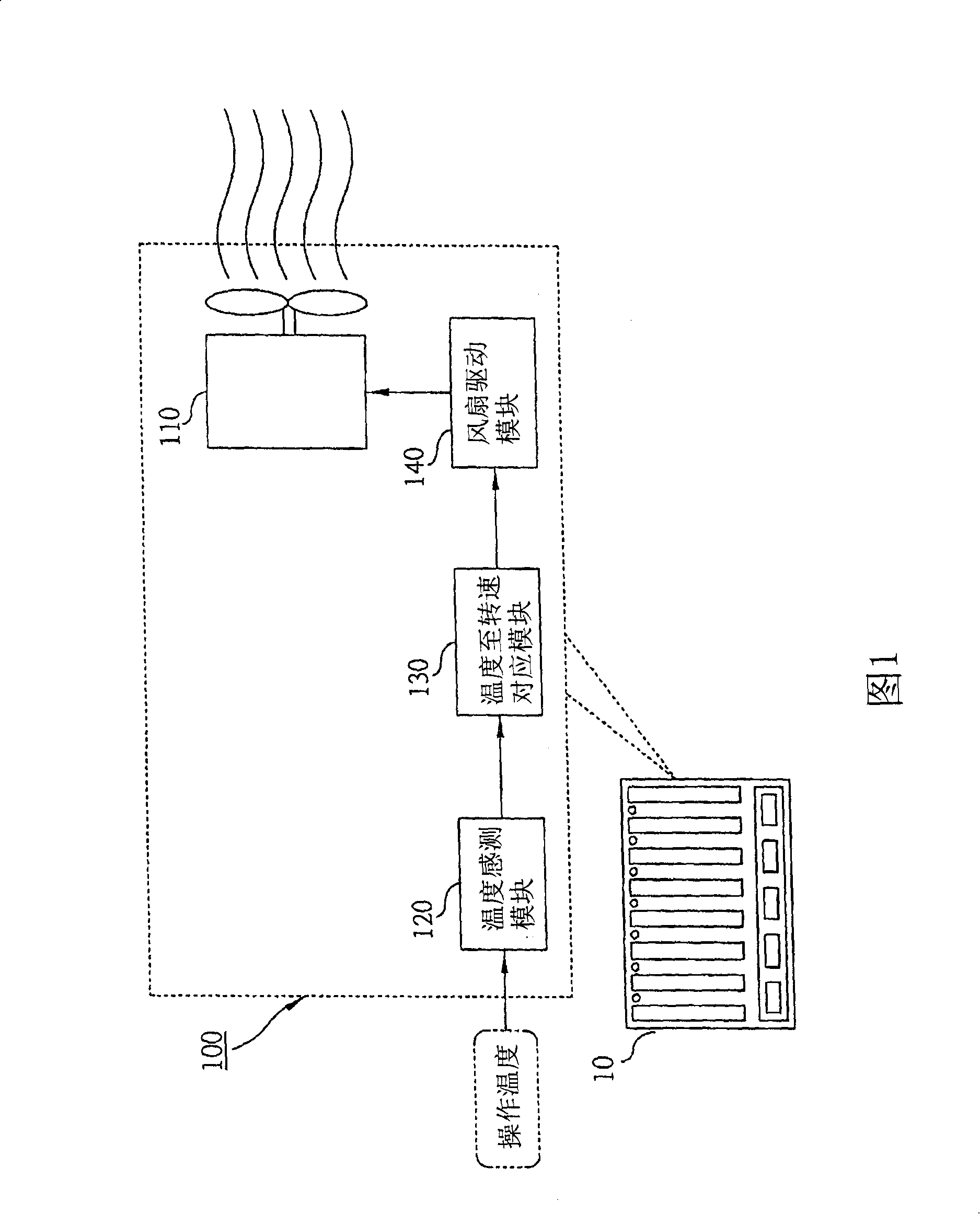

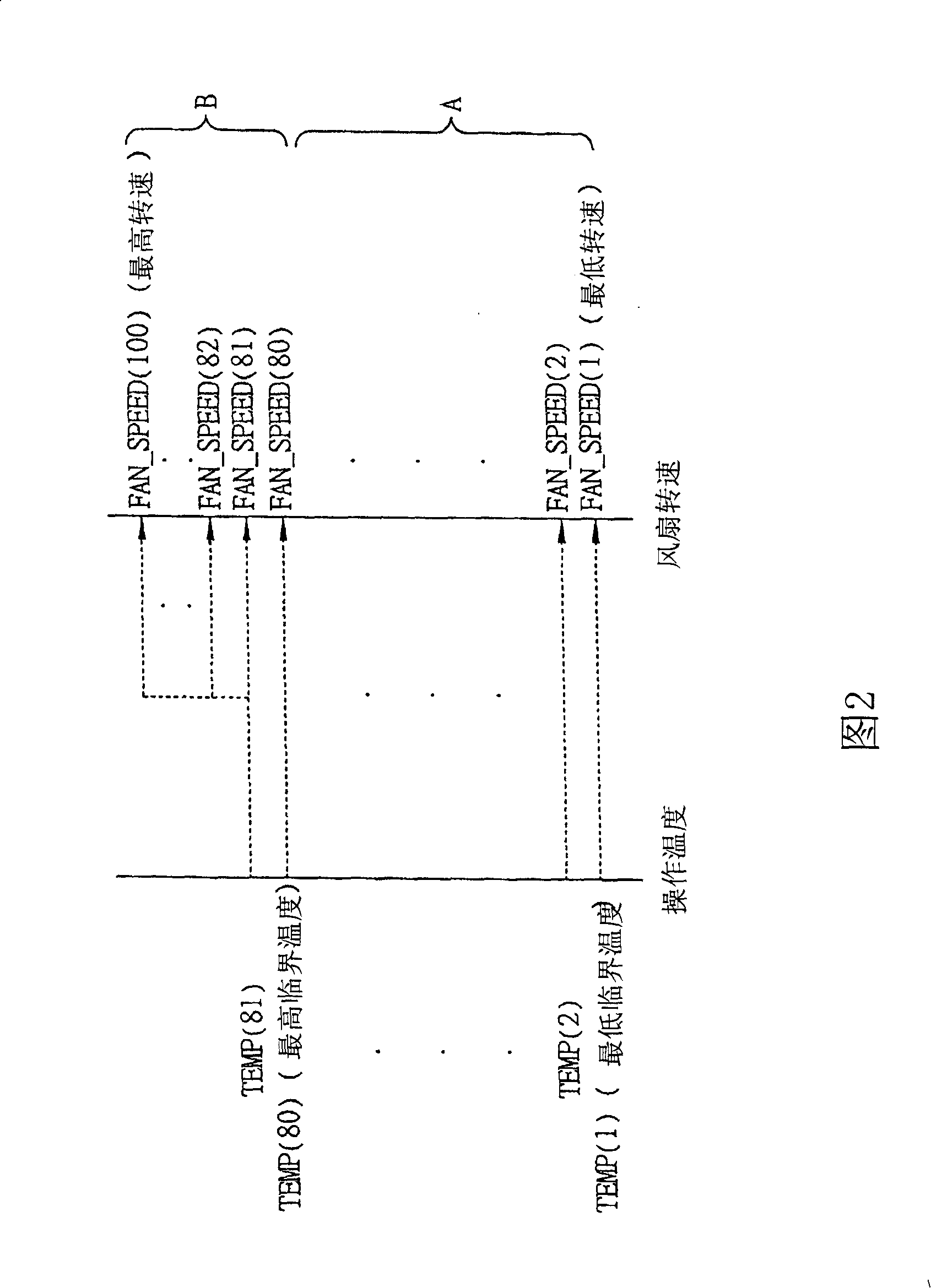

[0024] FIG. 1 shows the application method and internal structure of the dynamically controlled electronic equipment heat dissipation system of the present invention (such as the part enclosed by the dotted box indicated by the reference number 100 ). As shown in the figure, the dynamic control cooling system 100 for electronic equipment of the present invention is mounted on an electronic equipment 10 in practical applications, such as a blade server, desktop personal computer, or notebook computer (the blade server is used as an example below for illustration) , to provide a dynamically controlled cooling function for the blade server 10 .

[0025] As shown in FIG. 1, the internal basic structure of the dynamic control type electronic equipment cooling system 100 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com