Self-driven integral air compressor

An air compressor, self-driving technology, applied in valve drive devices, engine components, combustion engines, etc., can solve the problem of the large volume of air compressor equipment, the inconsistency between the output power and the power required by the compressor, and the power output of the power machine. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

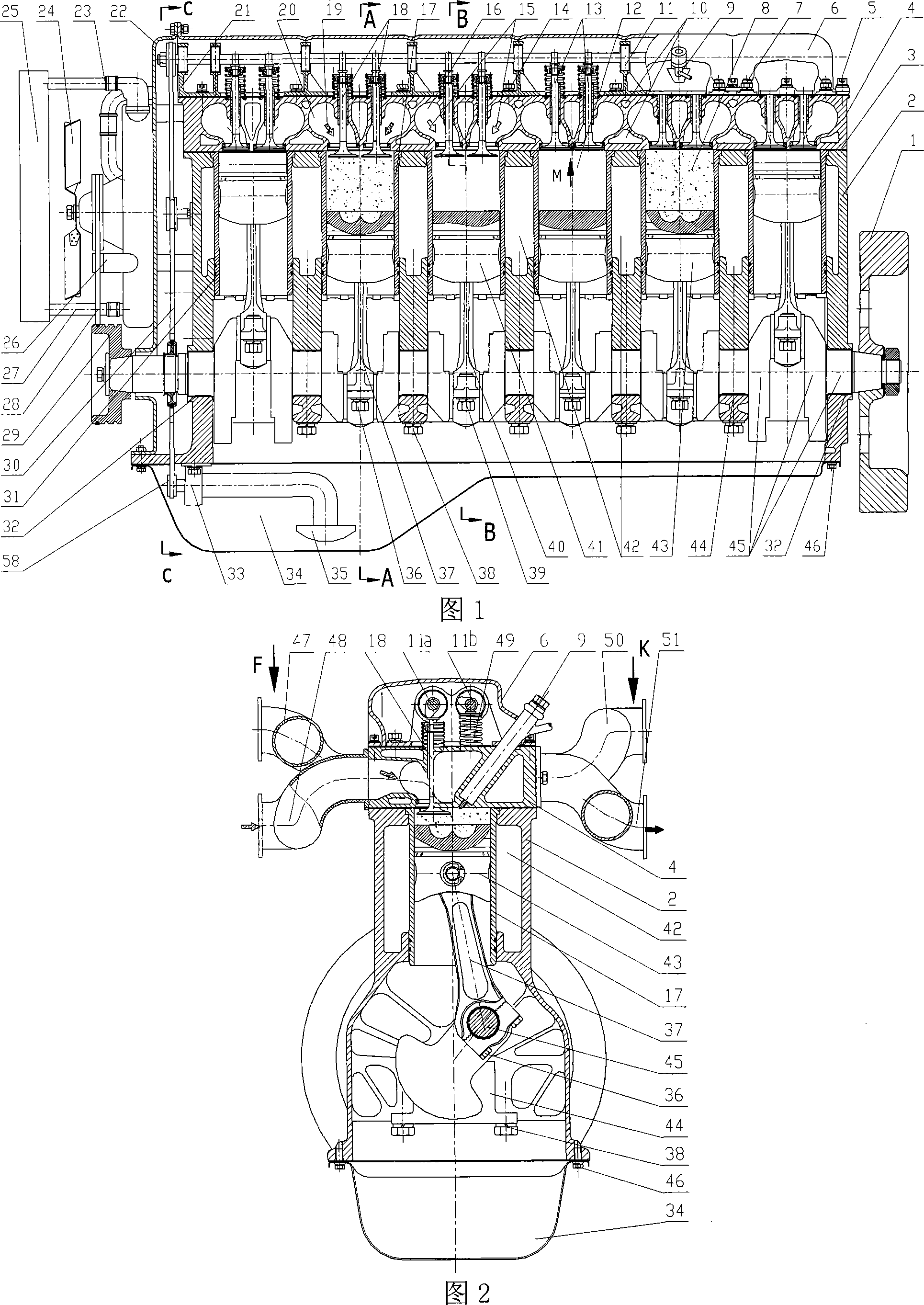

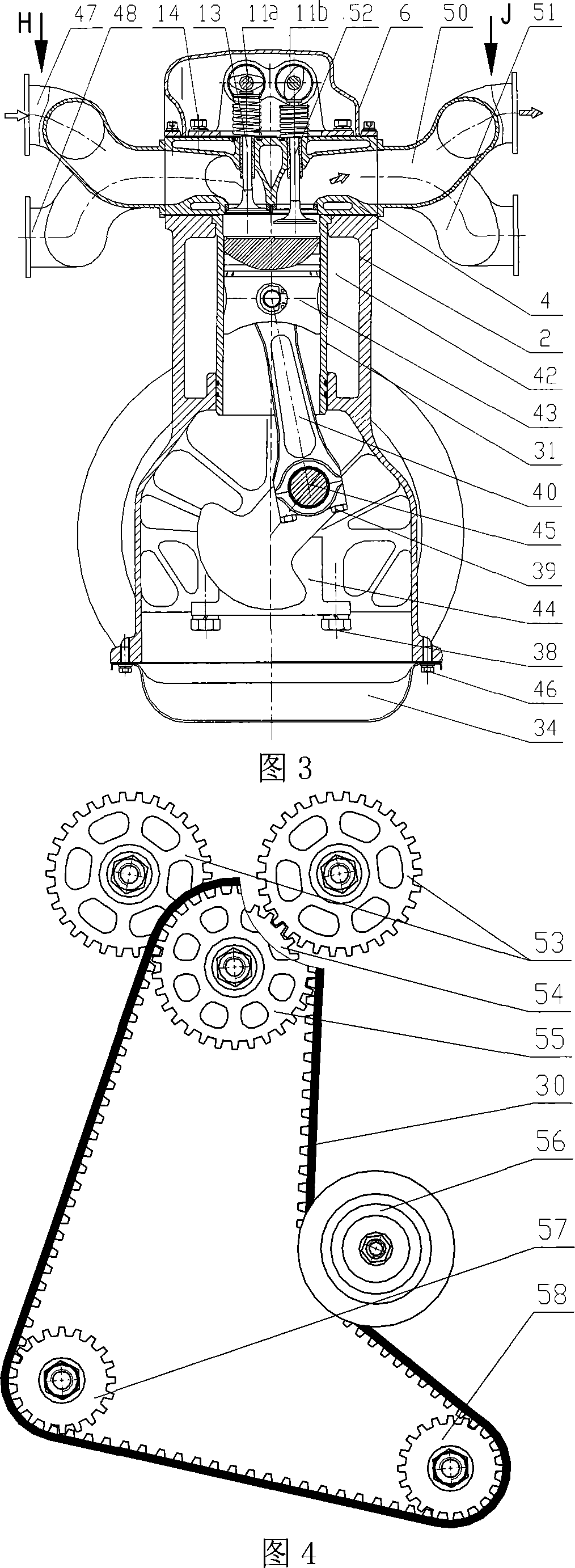

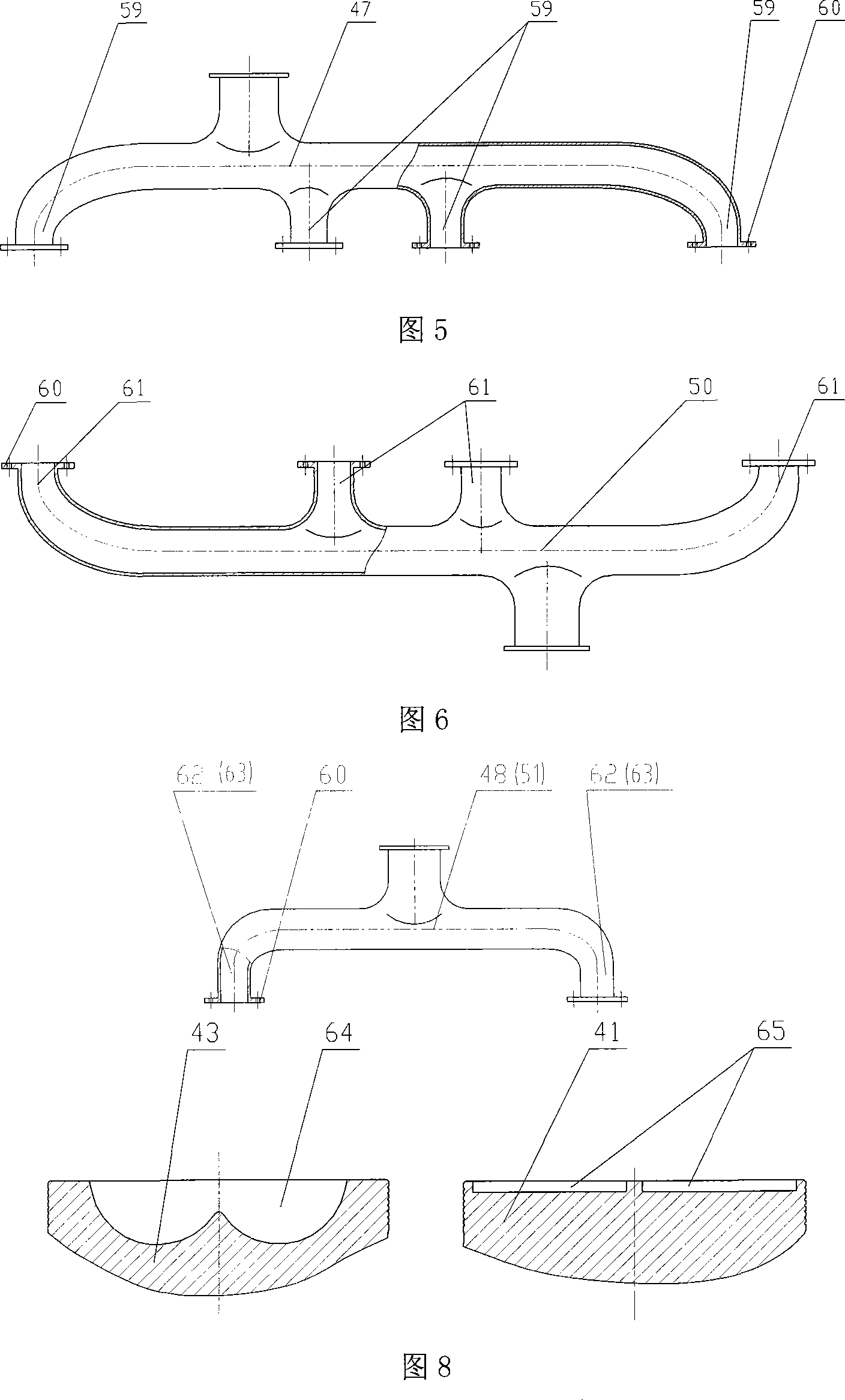

[0085] As shown in Figure 1, the power cylinder 8 and the compressor cylinder 12 of the self-driven air compressor are integrated on the same crankshaft 45, and all the main journals of the crankshaft 45 are installed on the bearing housing composed of the body 2 and the bearing cover 44 through the sliding bearing 32 Above, the number of sliding bearings 32 is the same as the number of main journals of the crankshaft 45 , and the bearing cover 44 and the body 2 are fastened together by the bearing cover bolt assembly 38 . A cylinder head 4 is provided at the upper end of the cylinder body 2, and a cylinder gasket 3 is arranged between the two to ensure that there is no water leakage or air leakage between the cylinder body 2 and the cylinder head 4. on body 2. The camshaft mounting seat 21 and the camshaft cover 6 are respectively installed on the cylinder head 4 through the bolt assembly 13 and the bolt assembly 5 . A fuel supply device 9 is arranged corresponding to each p...

Embodiment 2

[0098] The difference from technical solution 1 is that the exhaust gas use of the power cylinder has changed, mainly reflected in: ① cancel the exhaust gas turbocharger 70 between the intake and exhaust of the power cylinder; ② the exhaust pipe of the power cylinder 8 is leaving The exhaust pipe 51 of the power cylinder is divided into two parallel branches: one is equipped with a heat exchange valve 81 and connected in series with the heat exchanger 83; Converge into one road again, and flow through the exhaust gas post-processing device 71 to be emptied; ③The exhaust gas from the compression cylinder also passes through the heat exchanger 83 and is heated by the exhaust gas from the power cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com