Drying process and equipment for powdered urea formaldehyde condensate

A technology of powder urea-formaldehyde resin and drying process, which is applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve problems such as sticking to the wall, reduce sticking to the wall, reduce the phenomenon of sticking to the wall, and reduce adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

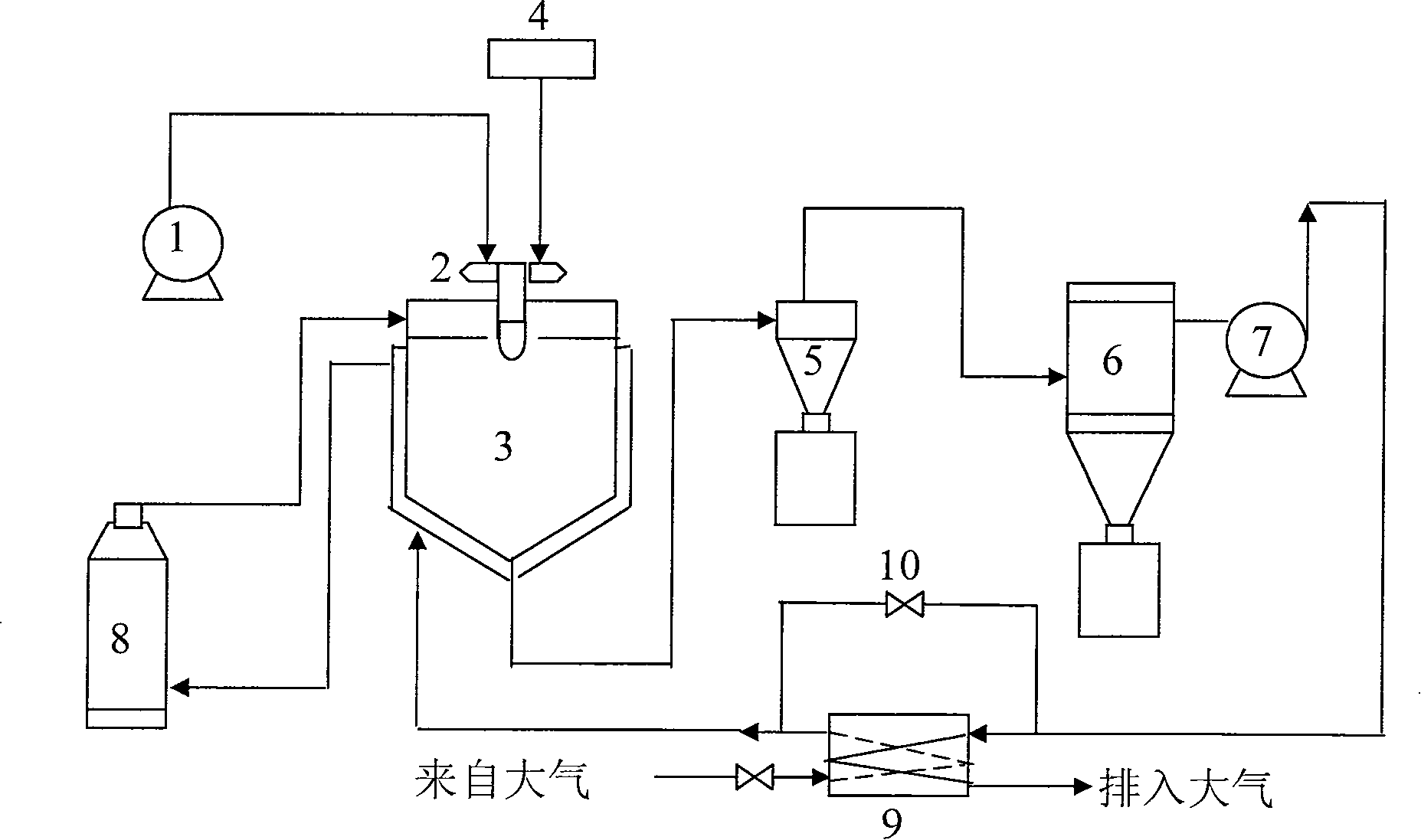

[0026] use figure 2 The powder urea-formaldehyde resin drying process shown is specifically: open the induced draft fan 7 and the air heater 8, the hot air passes through the drier, the cyclone separator 5, and the bag filter 6, and enters the primary air preheating side from the induced draft fan outlet Directly enter the interlayer air duct of the dryer, and enter the air heater after the second preheating. After 8 minutes, the temperature of the hot air reaches the process requirement of 155°C. Close the primary air preheating gas bypass, and adjust the peristaltic pump to add 1000ml of urea-formaldehyde resin emulsion to the second flow Type atomizing nozzle, the solid content of the urea-formaldehyde resin emulsion is 48%. Spray under the action of compressed air to form urea-formaldehyde resin mist droplets. After the mist droplets are dried by hot air in the drier, they enter the storage tank at the bottom of the cyclone separator and are dried continuously for 32 minu...

Embodiment 2

[0027] Example 2: Using figure 2The powder urea-formaldehyde resin drying process shown is specifically: open the induced draft fan 7 and the air heater 8, the hot air passes through the drier, the cyclone separator 5, and the bag filter 6, and enters the primary air preheating side from the induced draft fan outlet Directly enter the interlayer air duct of the dryer, and enter the air heater after the second preheating. After 5 minutes, the temperature of the hot air reaches the process requirement of 145°C. Close the primary air preheating gas bypass, and adjust the peristaltic pump to add 1000ml of urea-formaldehyde resin emulsion to the second flow. Type atomizing nozzle, the solid content of the urea-formaldehyde resin emulsion is 48%. Spray under the action of compressed air to form urea-formaldehyde resin mist droplets. After the mist droplets are dried by hot air in the dryer, they enter the storage tank at the bottom of the cyclone separator and dry continuously for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com