Injection type low-temperature waste-heat power generation refrigerating method

A low-temperature waste heat and refrigeration method technology, which is applied in the direction of refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as complex operation and limited cooling capacity, achieve safe and reliable process, strengthen refrigeration effect, and improve overall energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

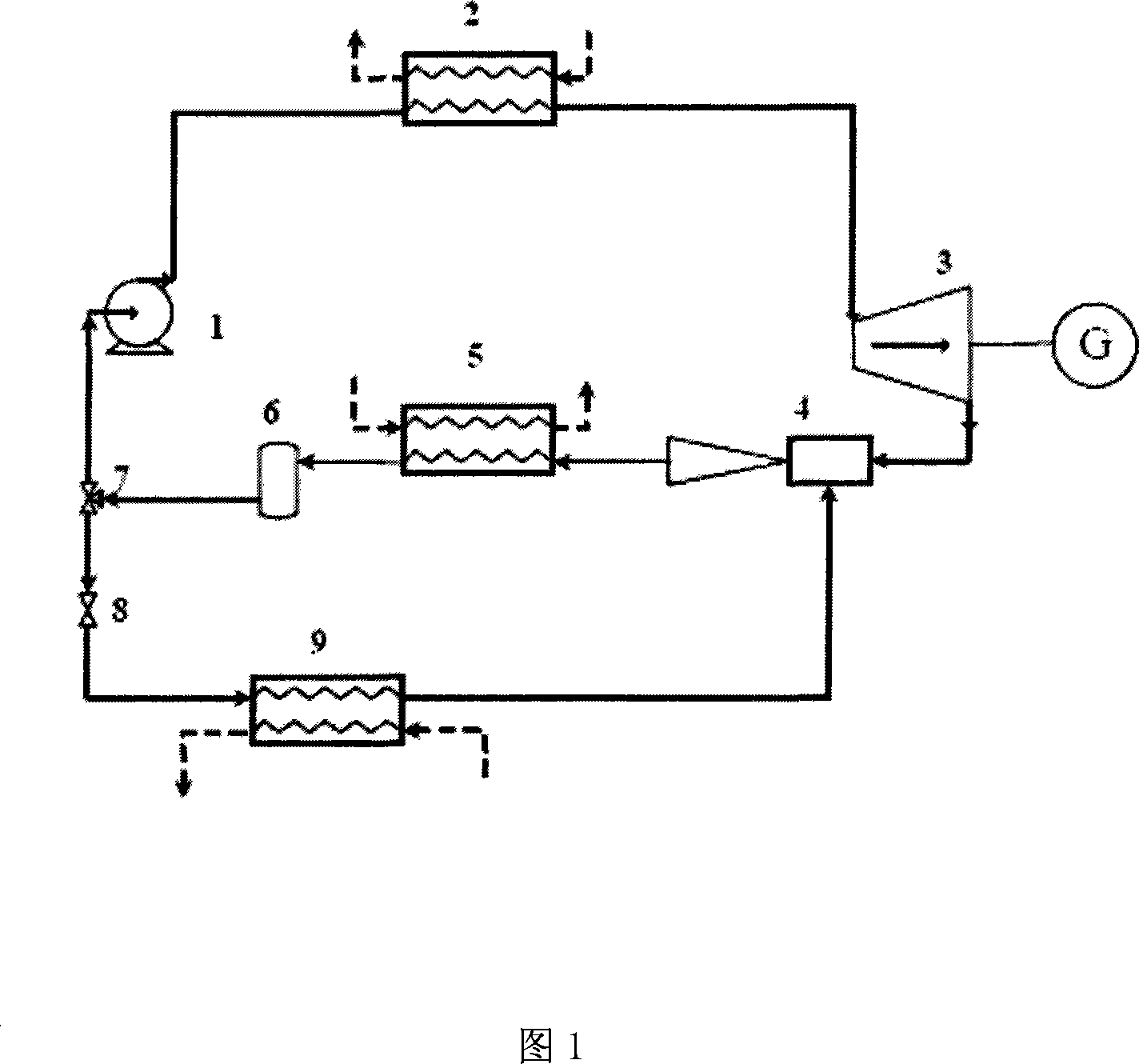

Image

Examples

Embodiment 1

[0024] Taking the working fluid R245fa as an example, the waste heat temperature is 150°C, the evaporation pressure of the waste heat exchanger is 1.26MPa, the turbine expansion ratio is 2.5, the turbine outlet pressure is 0.5MPa, the condensation temperature of the condenser is 25°C, the condensation pressure is 0.15MPa, and the evaporator evaporates The temperature is 12°C, the evaporation pressure of the evaporator is 0.09MPa, the ambient temperature is 25°C, and the cooling water temperature is 10°C as the working parameters to illustrate the cycle flow. The parameters involved in the specific implementation process do not limit the present invention.

[0025] 1. The saturated liquid organic working medium R245fa at about 25°C is raised to 1.26MPa by the working medium pump and sent to the waste heat exchanger for heating.

[0026] 2. The liquid working medium R245fa is heated to about 105°C by the low-temperature waste heat of about 150°C in the waste heat exchanger, the ...

Embodiment 2

[0034] Taking the working fluid R123 as an example, the waste heat temperature is 250℃, the evaporation pressure of the waste heat exchanger is 1.76MPa, the expansion ratio of the turbine is 2.5, the outlet pressure of the turbine is 0.7MPa, the condensation temperature of the condenser is 30℃, the condensation pressure is 0.11MPa, and the evaporator evaporates The temperature is 10°C, the evaporation pressure of the evaporator is 0.05MPa, the ambient temperature is 25°C, and the cooling water temperature is 20°C as the working parameters to illustrate the cycle flow. The parameters involved in the specific implementation process do not limit the present invention.

[0035] 1. The saturated liquid organic working medium R123 at about 30°C is raised to 1.76MPa by the working medium pump and sent to the waste heat exchanger for heating.

[0036] 2. The liquid working medium R123 is heated to saturation by the low-temperature waste heat of about 250°C in the waste heat exchanger,...

Embodiment 3

[0044] Taking the working fluid R141b as an example, the waste heat temperature is 350°C, the evaporation pressure of the waste heat exchanger is 2.94MPa, the turbine expansion ratio is 2.5, the turbine outlet pressure is 1.18MPa, the condensation temperature of the condenser is 35°C, the condensation pressure is 0.12MPa, and the evaporator evaporates The temperature is 7°C, the evaporation pressure of the evaporator is 0.04MPa, the ambient temperature is 25°C, and the cooling water temperature is 25°C as the working parameters to illustrate the cycle flow. The parameters involved in the specific implementation process do not limit the present invention.

[0045] 1. The saturated liquid organic working medium R141b at about 35°C is raised to 2.94MPa by the working medium pump and sent to the waste heat exchanger for heating.

[0046] 2. The liquid working medium R141b is heated to saturation by the low-temperature waste heat of about 350°C in the waste heat exchanger, with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com