Compacting grouting and reinforcing technology for floor foundation of fly ash soil layer and backfilled stone layer in smelting workshop

A technology of compaction grouting and pulverized coal, applied in soil protection, infrastructure engineering, application, etc., to achieve the effects of low construction cost, high bearing capacity, and simple construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

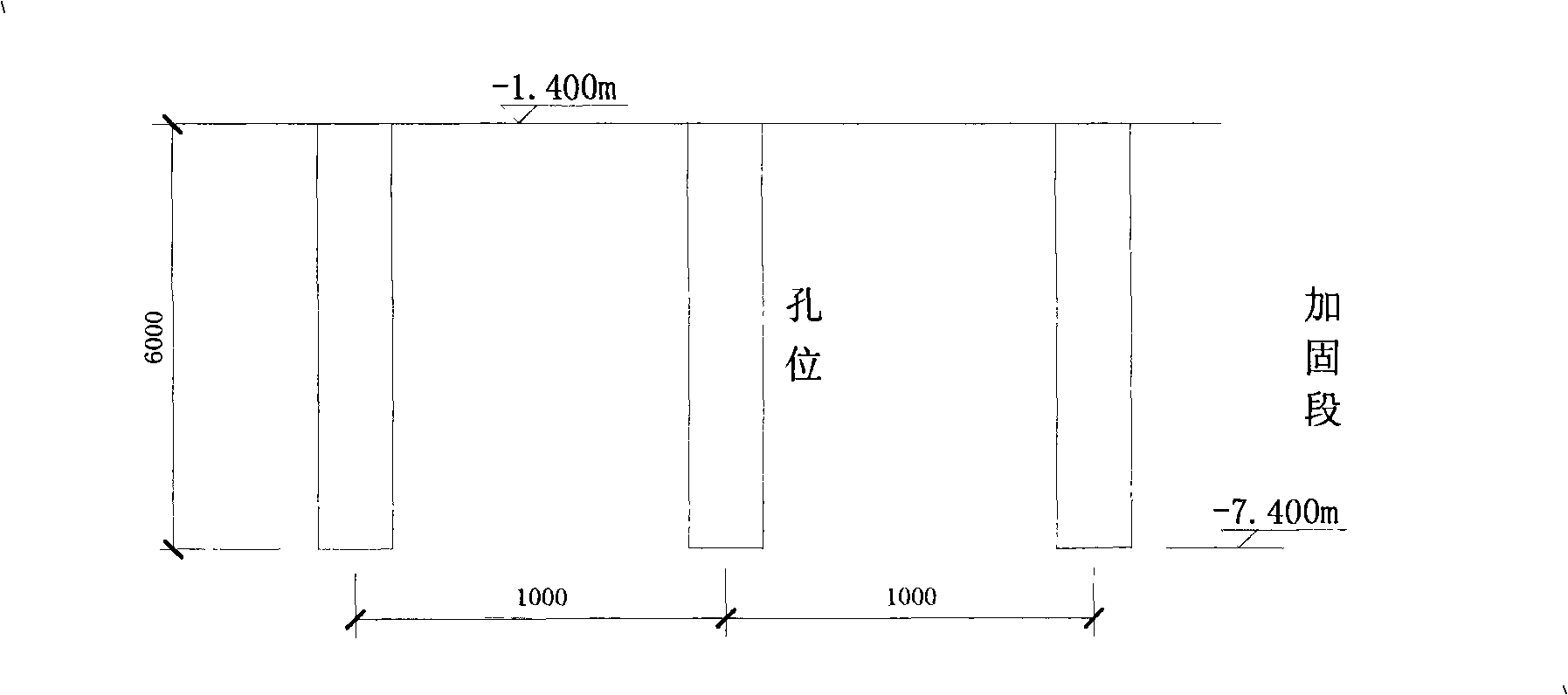

[0023] A compacting and grouting reinforcement process for the fly ash soil layer of the smelting workshop and the backfilling rock layer floor foundation of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

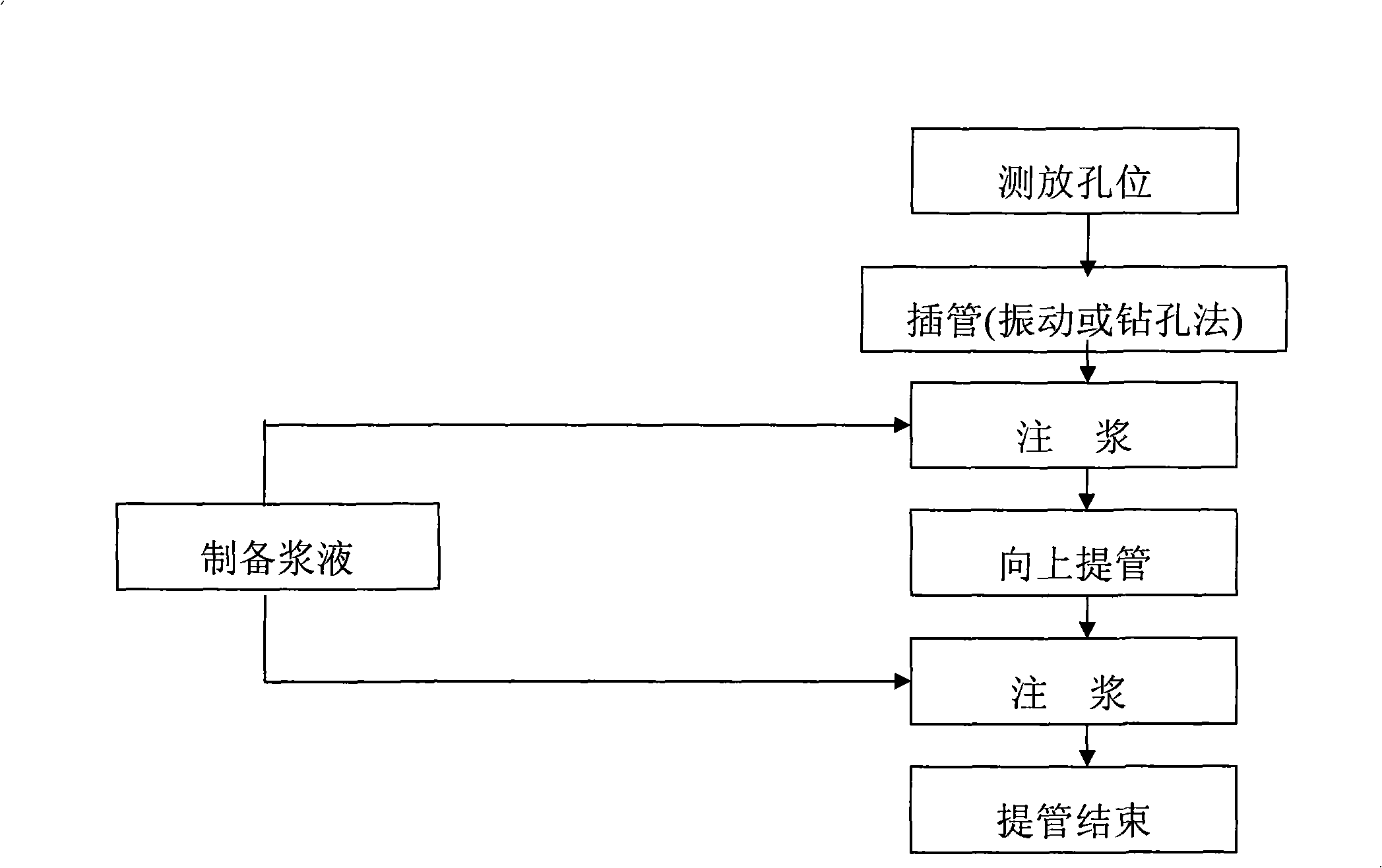

[0024] Depend on figure 1 As shown in the flow chart of the construction process of a compaction grouting reinforcement process for the fly ash soil layer of the smelting workshop and the backfilling rock layer floor foundation, the present invention includes measuring and releasing hole positions, intubation, slurry preparation, Grouting process:

[0025] (1) Measuring the hole position: According to the control axis, use a steel ruler to measure the hole position and mark it.

[0026] (2) Intubation: Vibration or drilling method is used for intubation. The grouting pipe adopts Φ43 metal pipe with plug. The total number of grouting pipes required for a single hole is configured according to the designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com