Drill

A technology of drill bit and main body, which is applied in the field of drill bit for drilling processing, which can solve the problems of inability to perform high precision, vibration, cutting edge breakage, etc., and achieve the effect of preventing the reduction of strength/rigidity, ensuring rigidity, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

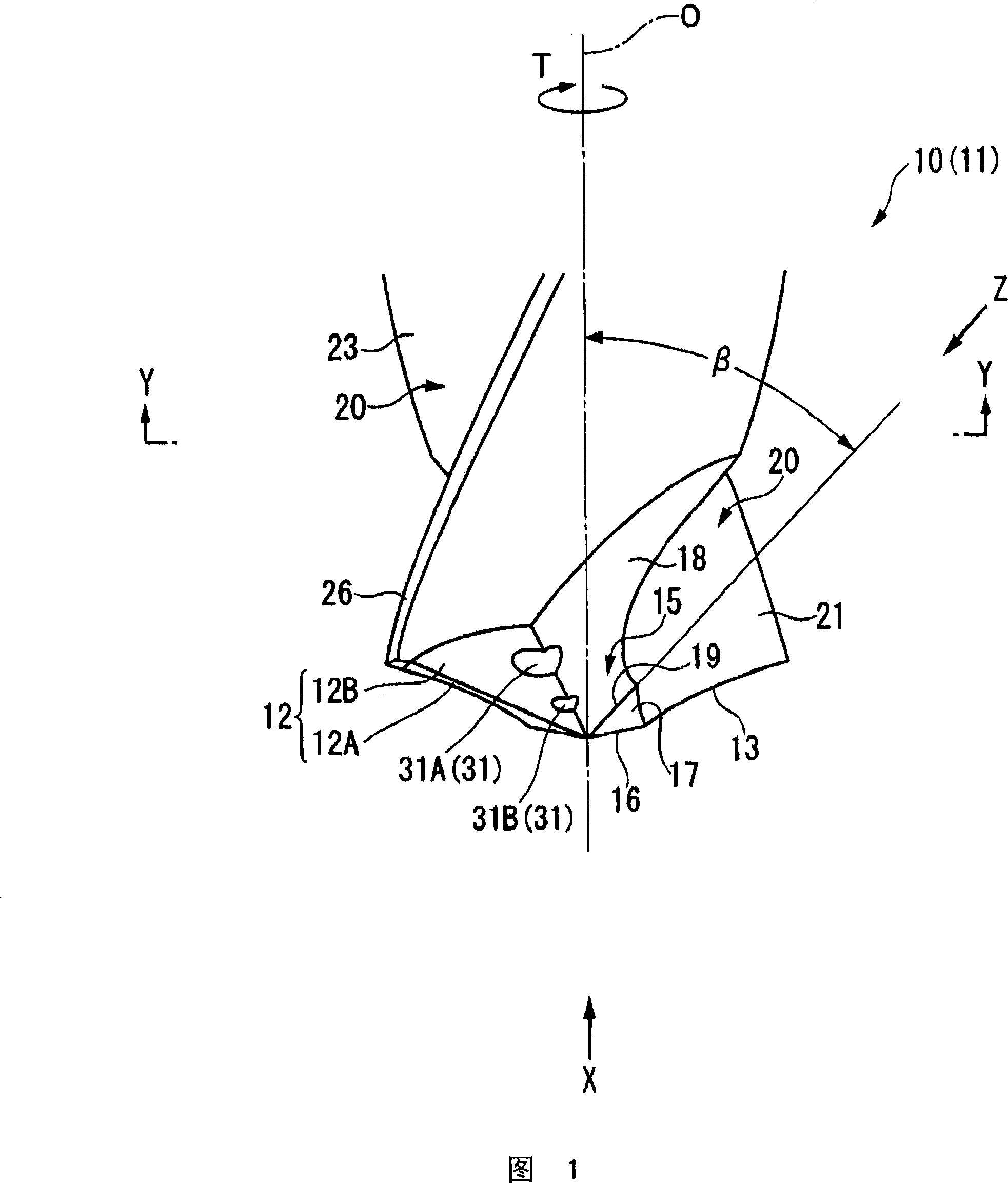

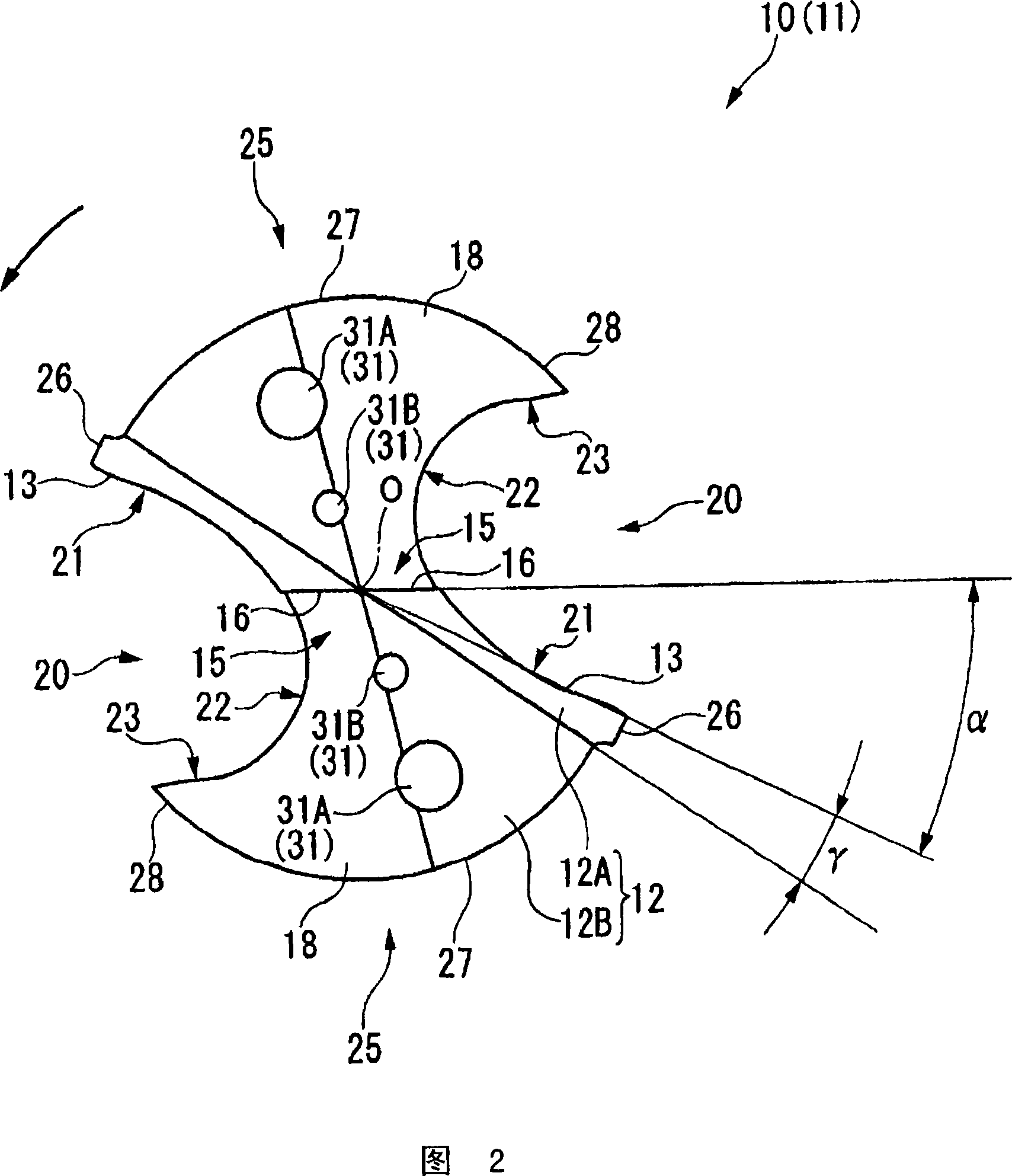

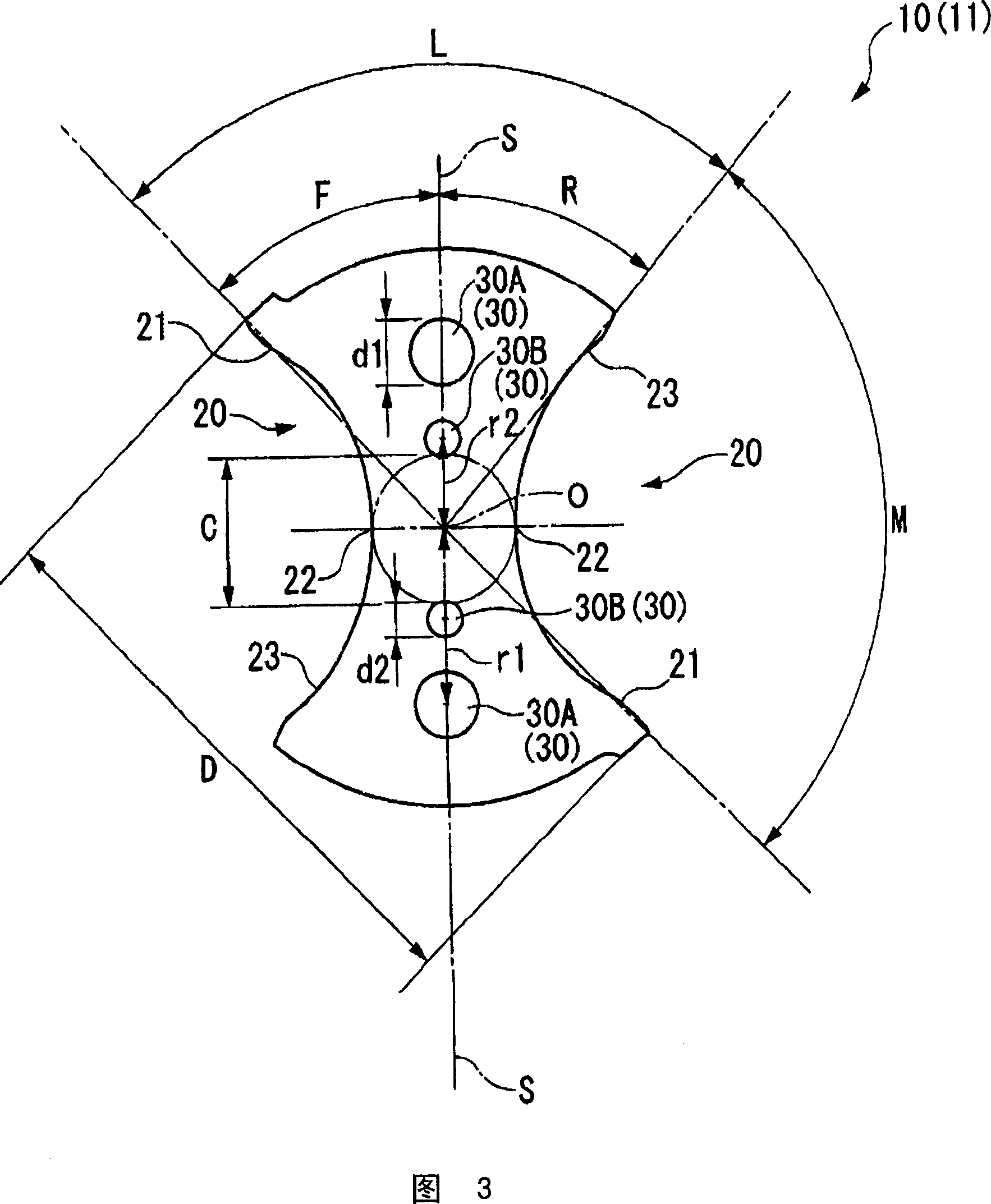

[0034] A drill which is an embodiment of the present invention will be described with reference to the drawings. A drill according to an embodiment of the present invention is shown from FIG. 1 to FIG. 3 .

[0035] The drill according to this embodiment is used when drilling a workpiece made of aluminum. The drill body 10 of this drill is made of a hard material such as cemented carbide, and as shown in FIG. The shank is gripped by a spindle of a machine tool or the like, and the tip side (lower side in FIG. 1 ) of the drill body 10 is used as the cutting edge portion 11 .

[0036] On the outer periphery of the cutting edge portion 11, a pair of chip discharge flutes 20, 20 are twisted toward the rear side in the drill rotation direction T at a constant twist angle from the tip relief surface 12 to the rear end side in the axis O direction. O is formed with 180° rotational symmetry. The chip discharge groove 20 has a wall surface 21 facing forward in the drill rotation dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com