Fluidized-bed normal pressure spray-freezing drying method and device

A spray freeze-drying and fluidized-bed technology, which is applied to drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of technology promotion and application limitations, large equipment investment, long production cycle and other problems, and achieves an environment-free environment. The effect of pollution, low production cycle and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

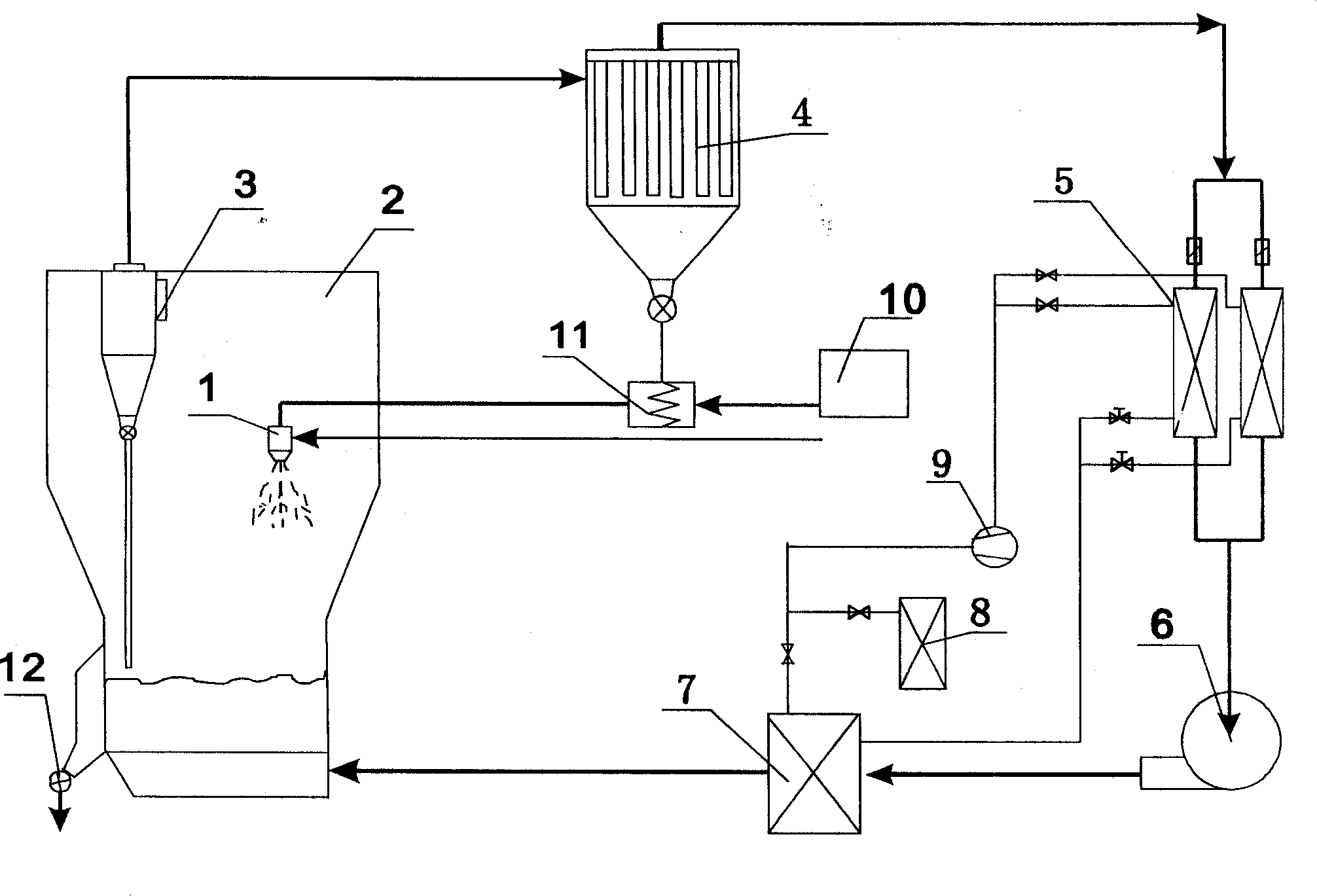

[0013] like figure 1 As shown, in this normal-pressure spray freeze-drying system, the liquid raw material to be dried from the raw material tank 10 is first atomized and frozen into fine solid particles by the low-temperature two-fluid nozzle 1 in the drier 2, according to product characteristics and quality Requirements, the atomization medium is air or other inert gas, and the temperature is controlled at -15°C to -70°C. Most of the fine frozen solid particles sprayed and frozen by the low-temperature two-fluid nozzle are scattered in the fluidized bed at the bottom of the drying chamber by gravity. Using the principle of normal pressure freeze-drying and fluidization technology, the water is sublimated remove. The temperature of the drying medium of atmospheric freeze-drying is adjustable from -4°C to -40°C, and the partial pressure of water vapor in the drying medium is lower than 611.7 Pascal. According to the particle size and density of the product, the dryer can ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com