Preparation method for fluorescence metal nano particles

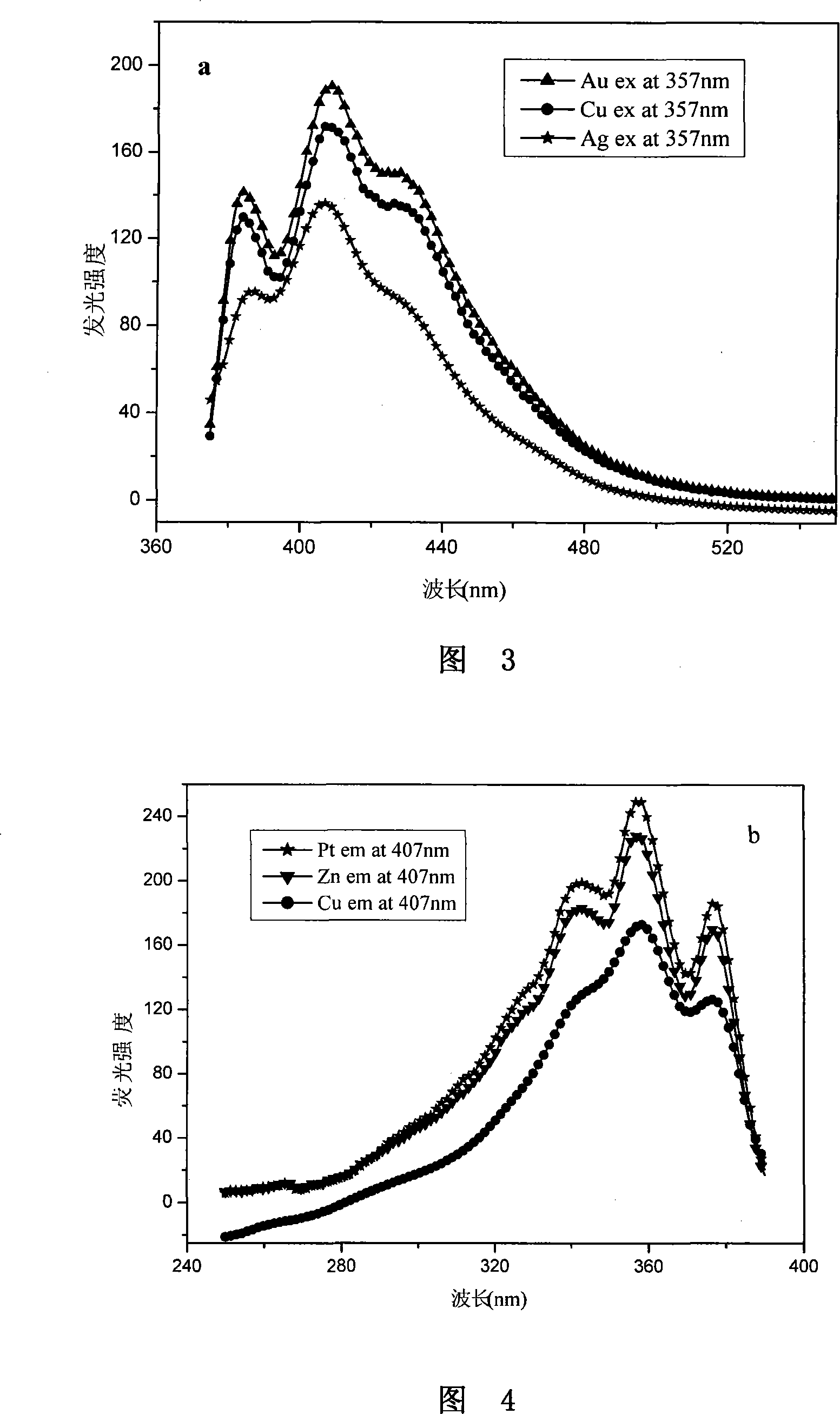

A technology of metal nanoparticles and fluorescence, which is applied in the field of preparation of fluorescent metal nanoparticles, can solve the problems of weak emission fluorescence intensity, complicated preparation methods, low quantum yield, etc., and achieve improved fluorescence properties, good product dispersibility, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a 50ml Erlenmeyer flask, add the CTAB of 1.0g, the n-butanol of 2.0g, the n-octane of 5.0g and 0.5g, the aqueous solution that concentration is 0.01mol / L silver nitrate, obtain metal ion microemulsion ; Add the CTAB of 1.0g in the Erlenmeyer flask of 50ml, the n-butanol of 2.0g, the n-octane of 5.0g and 0.5g, concentration are the aqueous solution of 0.1mol / L sodium borohydride, obtain reducing agent microemulsion; Ultrasonic dispersion of metal ion microemulsion and reducing agent microemulsion, mixed uniformly and transparently;

[0028] (2) Add the reducing agent microemulsion to the metal ion microemulsion at a rate of 10 drops per minute at a rate of 1:1 at a temperature of 10° C. under magnetic stirring at a stirring speed of 500 rpm. After the dropwise addition, 0.19 g of dimercaptohexane was added, and the reaction was continued for 1 hour.

[0029] (3) At room temperature, the mixed solution after the reaction in step (2) was left to stand for 12 hours,...

Embodiment 2

[0031] (1) in the conical flask of 50ml, add the CTAB of 3.0g, the n-butanol of 6.0g, the n-octane of 21g and 1.5g, concentration are the aqueous solution of 0.1mol / L chloroauric acid, obtain metal ion microemulsion ; Add the CTAB of 3.0g in a conical flask of 50ml, the n-butanol of 6.0g, the n-octane of 21g and 1.5g, the aqueous solution that concentration is 0.8mol / L sodium borohydride, obtain reducing agent microemulsion; The metal ion microemulsion and the reducing agent microemulsion are ultrasonically dispersed separately, and the mixing is uniform and transparent;

[0032](2) Add the reducing agent microemulsion into the metal ion microemulsion at a rate of 100 drops per minute at a temperature of 30° C. under magnetic stirring at a stirring speed of 2000 rpm. After the dropwise addition, 0.32 g of dimercaptohexane was added, and the reaction was continued for 4 hours.

[0033] (3) At room temperature, the mixed solution after the reaction in step (2) was left to stand...

Embodiment 3

[0035] (1) in the conical flask of 50ml, add the CTAB of 1.0g, the n-butanol of 6.0g, the n-octane of 5.0g and 0.5g, the aqueous solution that concentration is 0.1mol / L cupric chloride, obtain metal ion Emulsion; in a 50ml conical flask, add 1.0g of CTAB, 6.0g of n-butanol, 5.0g of n-octane and 0.5g, a concentration of 0.1mol / L sodium borohydride in water to obtain a reducing agent microemulsion ; The metal ion microemulsion and the reducing agent microemulsion are ultrasonically dispersed, mixed uniformly and transparent.

[0036] (2) Add the reducing agent microemulsion into the metal ion microemulsion at a rate of 50 drops per minute at a temperature of 20° C. under magnetic stirring at a stirring speed of 1000 rpm. After the dropwise addition, add 0.25g of dimercaptohexane and continue to react for 4 hours

[0037] (3) At room temperature, the mixed solution after the reaction in step (2) was left to stand for 24 hours, so that the suspended matter therein was completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com