Method for preparing lactulose by co-immobilized lactose enzyme and glucose isomerase

A technology of glucose isomerase and lactulase, which is applied in the field of lactulose preparation, can solve problems such as syrup purification and crystallization difficulties, catalyst separation difficulties, and severe lactulose conditions, so as to achieve light product color, lower enzyme cost, The effect of simplified purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Prepare 20 mL of lactose solution, heat slightly to dissolve the lactose, add 100 U of co-immobilized lactase and glucose isomerase for batch reaction, react at a certain temperature, pH and time, and recover the co-immobilized enzyme after the reaction Gel particles.

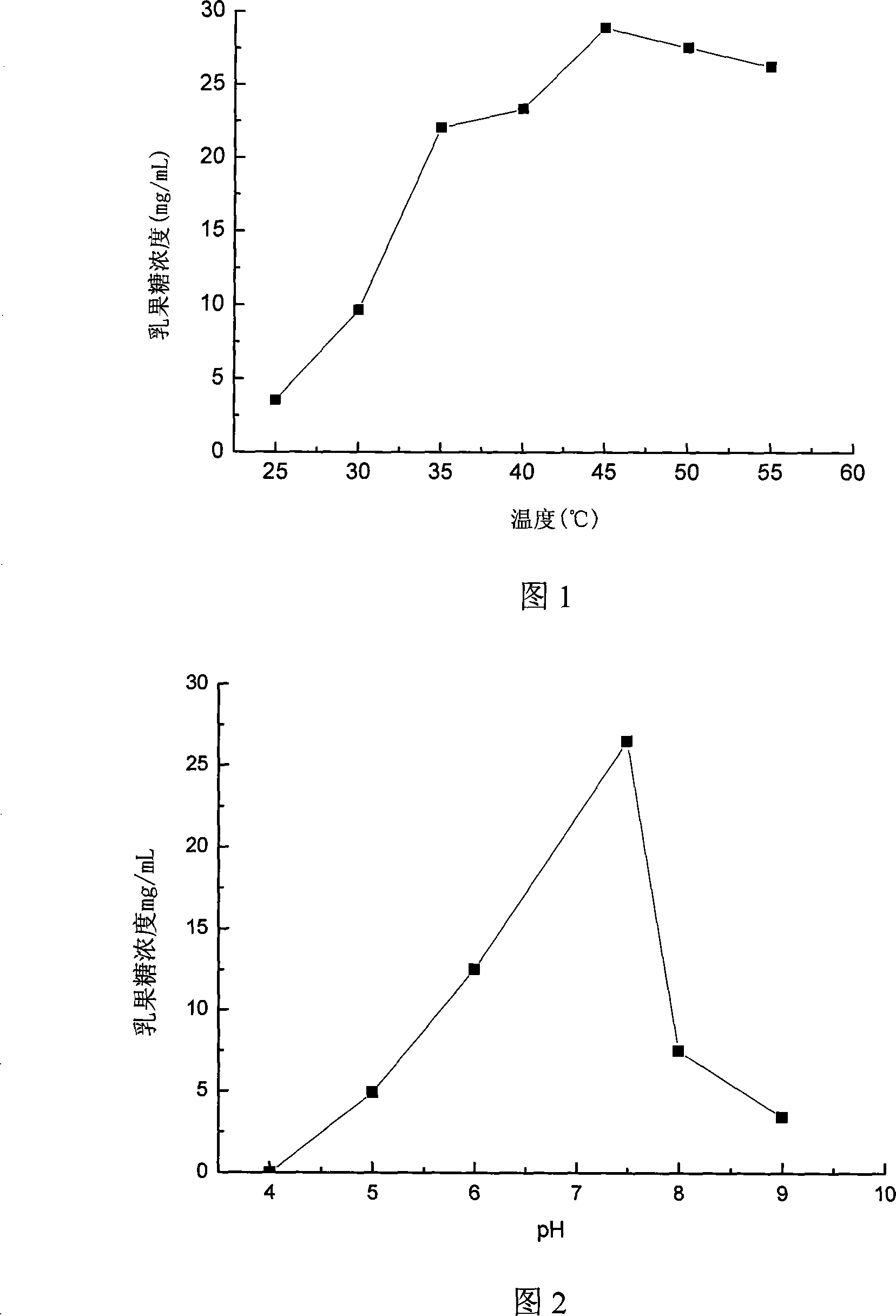

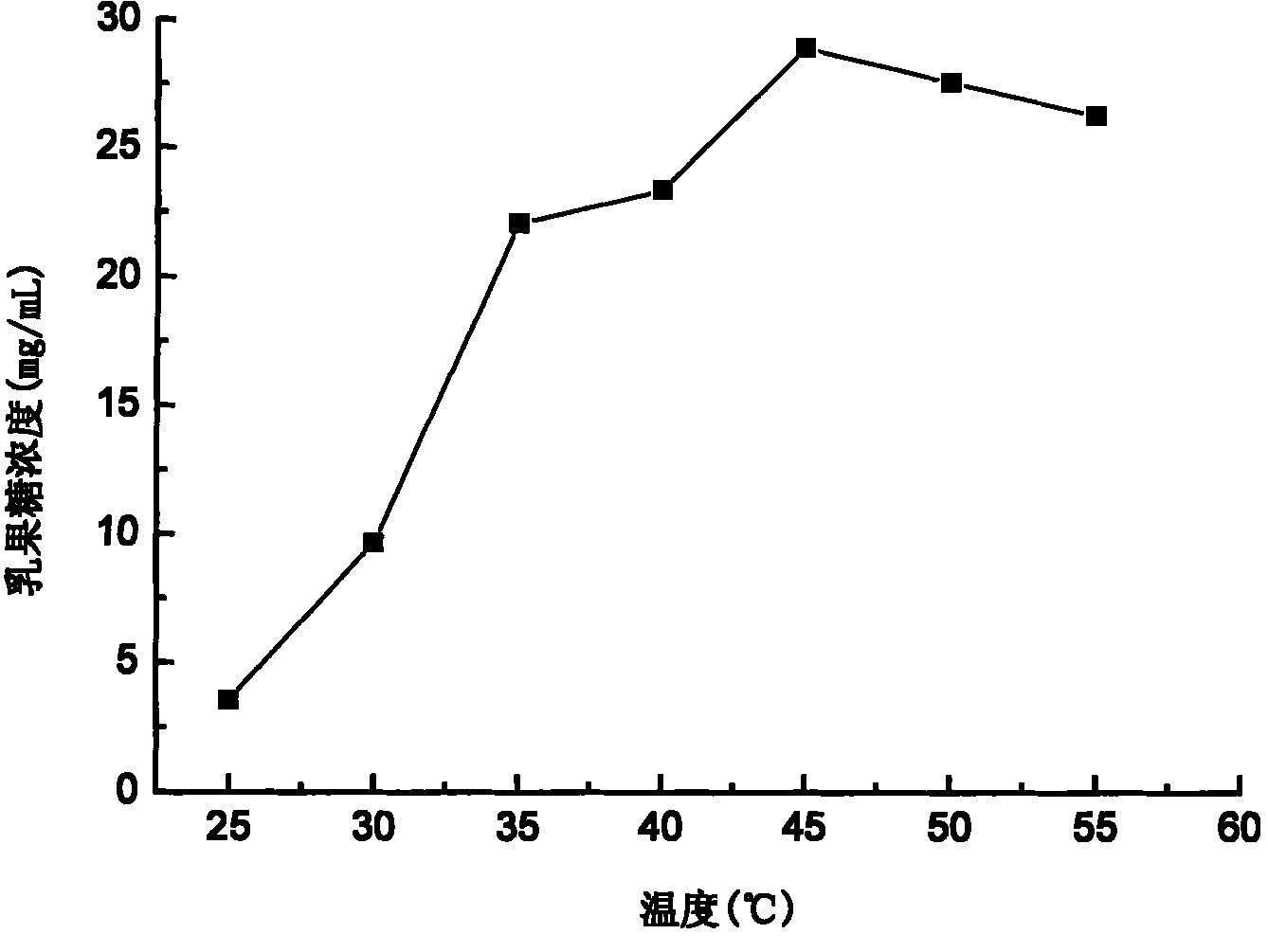

[0037] figure 1 The effects of temperatures of 25°C, 30°C, 35°C, 40°C, 45°C, 50°C and 55°C on the production of lactulose by co-immobilized lactase and glucose isomerase were shown. As shown in the figure, the optimum temperature is 45°C.

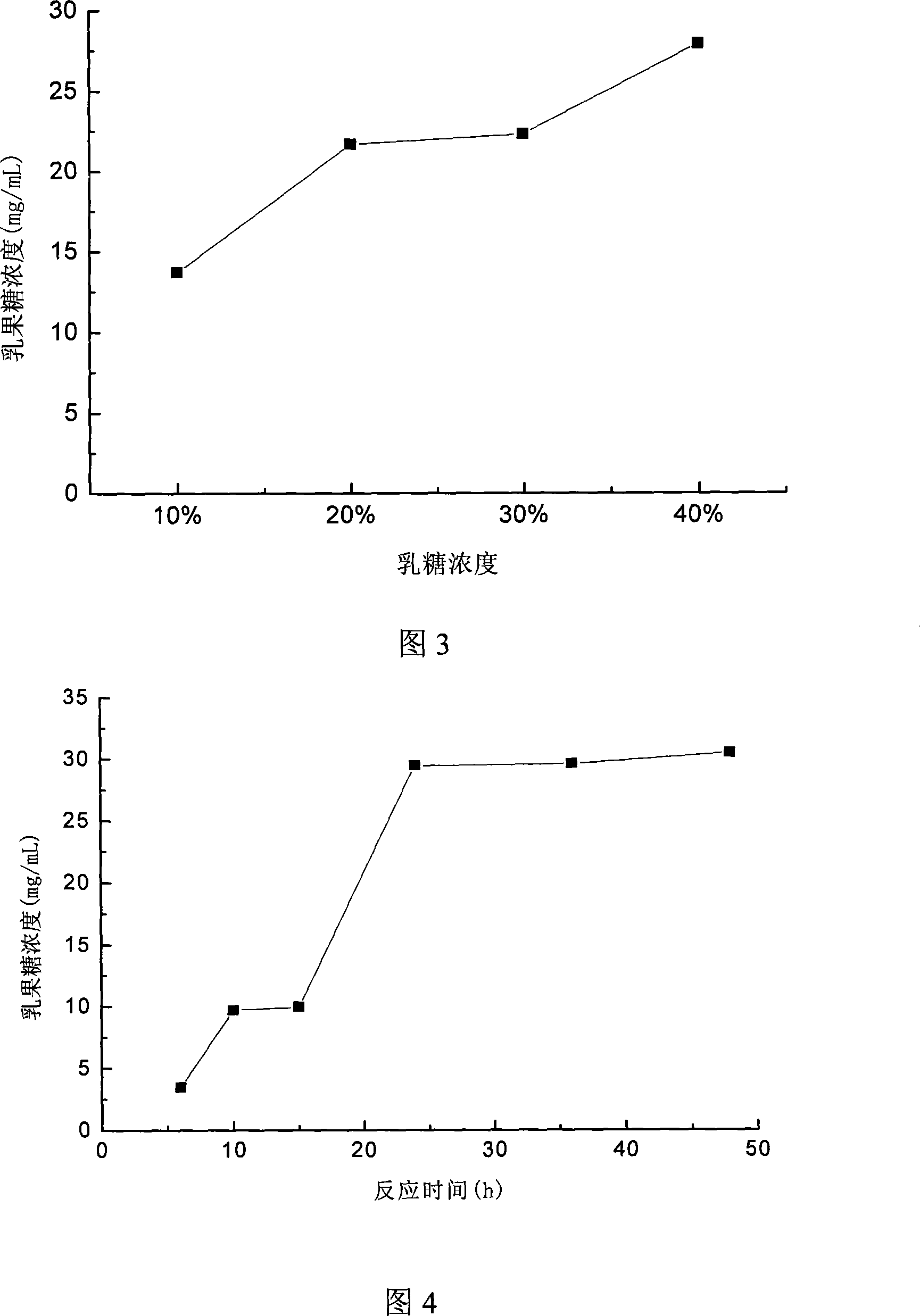

[0038] figure 2 The effects of pH 4, 5, 6, 7.5, 8 and 9 on the production of lactulose by co-immobilized lactase and glucose isomerase were shown. As shown, the optimum pH is 7.5.

[0039] image 3 The effects of lactose concentrations of 10%, 20%, 30% and 40% on the production of lactulose by co-immobilized lactase and glucose isomerase were shown. As shown, the optimum lactose concentration is 40%.

[0040] Figure 4 The effects of reaction time ...

Embodiment 2

[0041] Example 2: first immobilize free-state lactase and glucose isomerase through a 60-mesh nylon mesh, and then make an immobilized enzyme column. The thermostatic enzyme reaction column used has a diameter of 26 mm and a height of 200 mm. The column volume of the co-immobilized enzyme is 40mL, and the total activity is 2580U. Make lactose into a 30% (w / w) solution, adjust the pH to 7, feed the reaction from top to bottom, keep the temperature at 50±1°C, pass through the co-immobilized enzyme reaction column at a constant speed of 0.06mL / min, operate in one pass and collect reaction solution to obtain the product lactulose solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com