Method for preparing ceramic fiber precursor

A ceramic fiber and precursor technology, applied in the field of polymer material preparation, can solve problems such as unfavorable spinning process and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

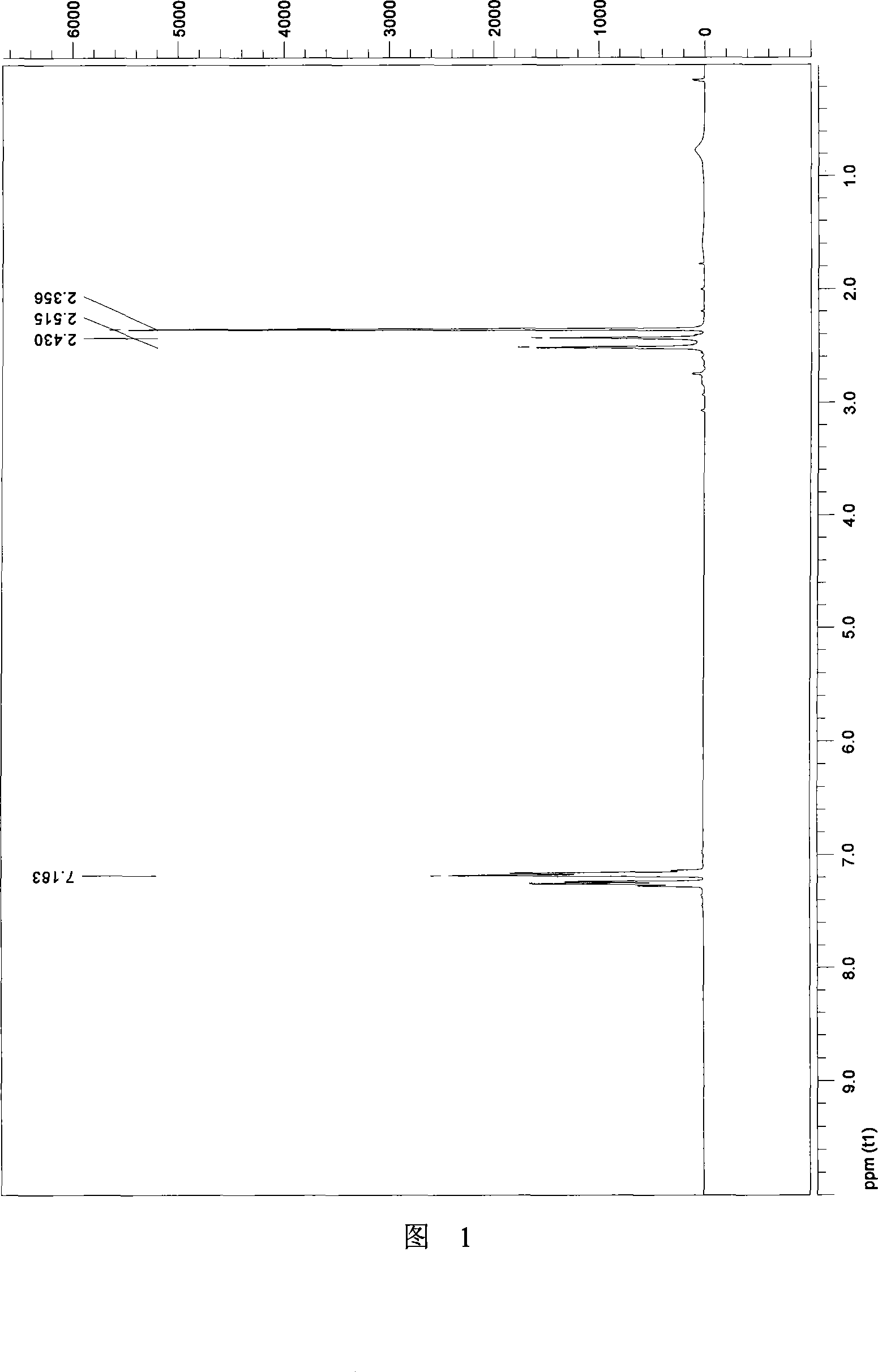

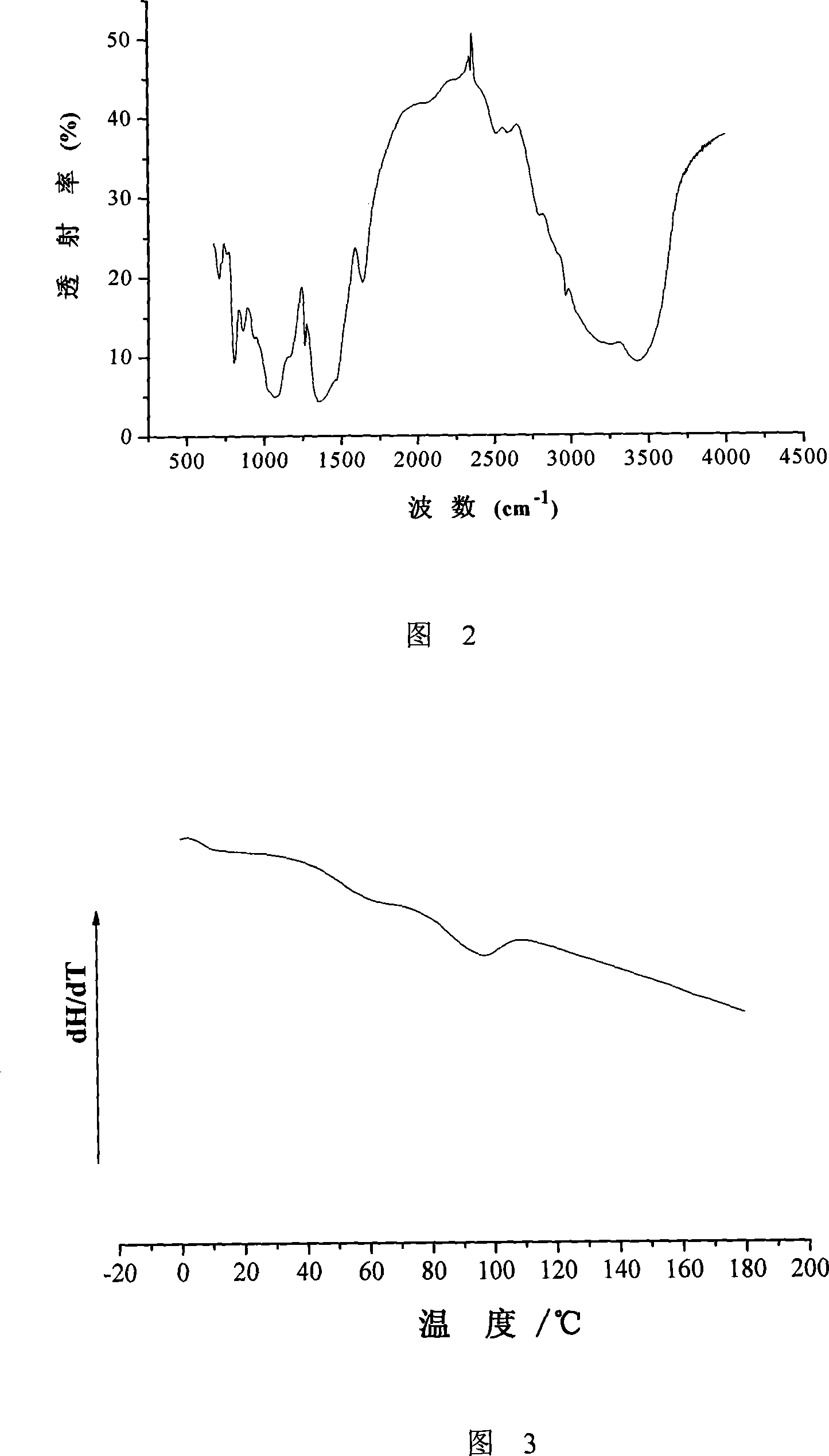

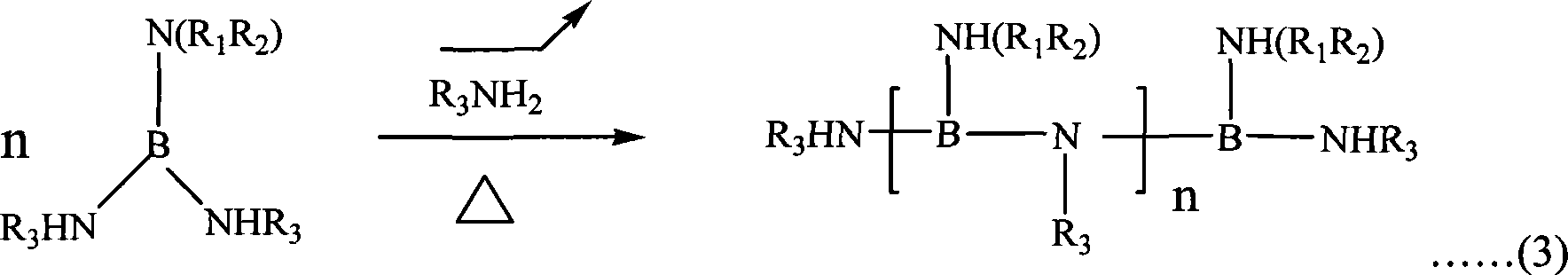

[0025] (1) Preparation of small molecular monomers: Take 26.5ml (0.2mol) of a triethylamine solution (volume ratio 1:1) with a concentration of 7.55mol / l dimethylamine in a 250ml single-necked flask, and move the flask to PSL -1800 type magnetic stirring cryogenic tank, temperature -80°C, replace the air in the flask with nitrogen; condense 23.4g (0.2mol) of boron trichloride from the steel cylinder into the reaction vessel through the tetrafluoroethylene tube; after condensation, With magnetic stirring, react for 5 hours; rise to room temperature and stir for 1 hour to produce a yellow precipitate; filter under nitrogen protection, wash the precipitate several times with 50ml of anhydrous toluene, combine the washings and filtrate; transfer the filtrate and washings to a 250ml dry In the single-necked flask, still placed in a low-temperature tank at a temperature of -80°C, transfer 80ml of anhydrous toluene solution of methylamine (volume ratio: 1:1) into a 250ml constant pres...

Embodiment 2

[0029] (1) Preparation of small molecular monomers: take 30ml (0.15mol) of triethylamine solution with a concentration of 5mol / l diethylamine in a 250ml single-necked flask, and move the flask to a PSL-1800 type magnetic stirring low-temperature tank. -80°C, replace the air in the flask with argon; condense 17.55g (0.15mol) of boron trichloride from the steel cylinder into the reaction vessel through a tetrafluoroethylene tube; after condensation, with magnetic stirring, react for 10h; then Rise to room temperature and stir for 4 hours, producing a yellow precipitate; filter under argon protection, wash the precipitate several times with 50ml of n-hexane, combine the washings and filtrate; transfer the filtrate and washings to a 250ml dry single-necked flask, and keep at temperature In a low-temperature tank at -80°C, transfer 80ml of methylamine n-hexane solution (volume ratio: 1:1) into a 250ml constant pressure funnel, slowly add it dropwise into the flask, and stir it magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com