Special composite material and uses thereof

A composite material and mixture technology, applied in special composite materials and their application fields, can solve the problems of difficult construction, unreliability, high price, etc., and achieve the effects of easy industrialization, long service life of equipment, and reliable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

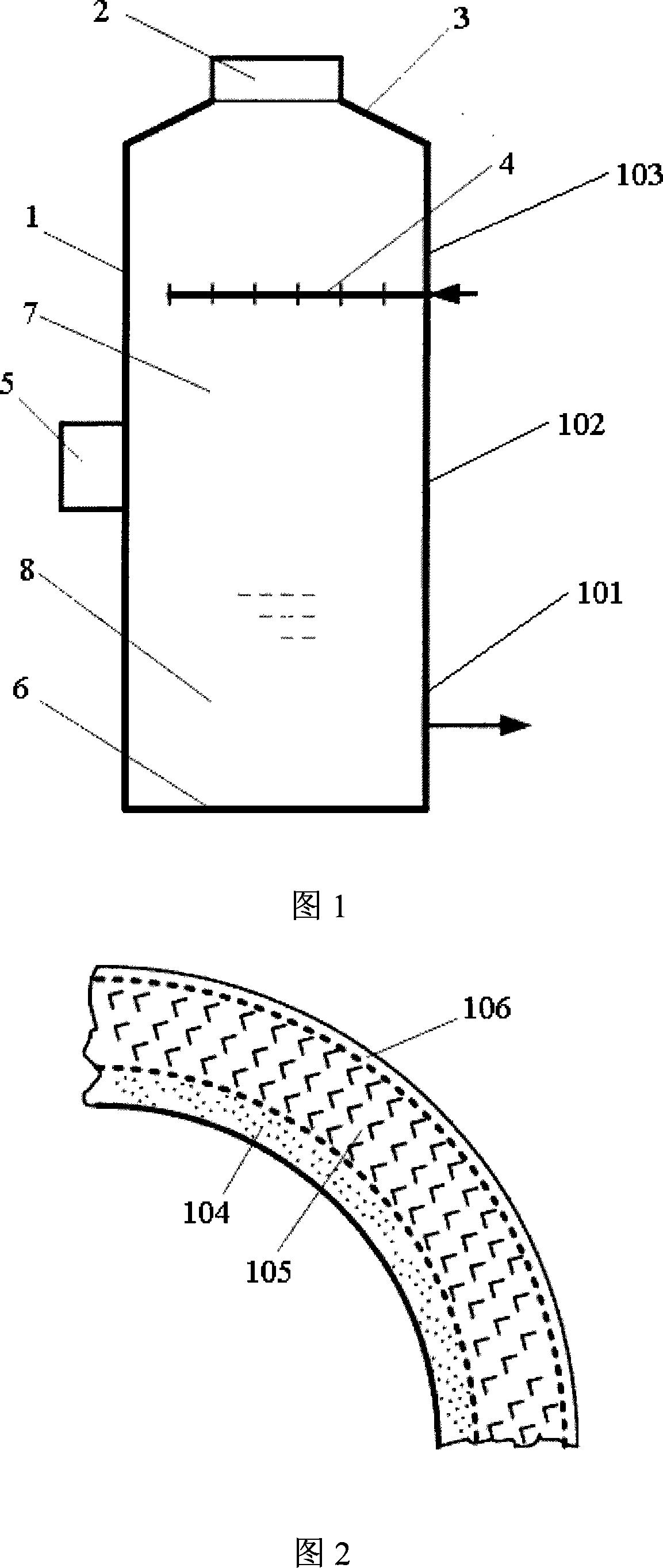

[0066] The preparation of a composite smoke exhaust and sulfur removal tower is as follows:

[0067] The diameter of the tower body is 9m, the total height is 25m, and the top flue gas connecting pipe 2 is located at the center of the top of the tower.

[0068] The organic resin is a polymer of monounsaturated organic acid and epoxy resin, the corresponding monounsaturated organic acid is acrylic acid, and the epoxy resin is bisphenol A type epoxy resin;

[0069] In the resin curing aid, the parts by weight ratio of each component is:

[0070] 2.5 parts of methyl ethyl ketone peroxide, 3 parts of cobalt naphthenate, 0.0 part of organic amine;

[0071] The tower body 1 is vertically divided into a lower section 101 , a middle section 102 and an upper section 103 .

[0072] The height of the lower section 101 is 12m, and the thickness changes from bottom to top, the height of 0-1m is 65mm, the height of 1-4m is 50mm, and the height of 4-12m is 40mm;

[0073] The height of the...

Embodiment 2

[0090] Preparation of the composite smoke and sulfur removal tower of Fig. 1 and Fig. 2:

[0091] The diameter of the tower body is 12m, and the total height is 28m. The top flue gas connecting pipe 2 is located on the tower body 1 close to the periphery of the tower top.

[0092] The organic resin is a polymer of monounsaturated organic acid and epoxy resin, the corresponding monounsaturated organic acid is methacrylic acid, and the epoxy resin is novolac epoxy resin;

[0093] Resin curing aids are organic peroxides, organic acid cobalt and organic amines;

[0094] The organic peroxide is methyl ethyl ketone peroxide, the cobalt organic acid is cobalt naphthenate, and the organic amine is diethylaniline;

[0095] In the resin curing aid, the parts by weight ratio of each component is:

[0096] 3 parts of methyl ethyl ketone peroxide, 2 parts of cobalt naphthenate, 2 parts of organic amine

[0097] The tower body 1 is vertically divided into a lower section 101 , a middle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com