Subacidity cation exchange fiber and method for preparing fabric thereof

A technology of cation exchange and fiber fabric, applied in the field of preparation of functional fiber materials, can solve the problems of large consumption of raw materials, complex process and high production cost, and achieve the effects of shortened reaction time, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

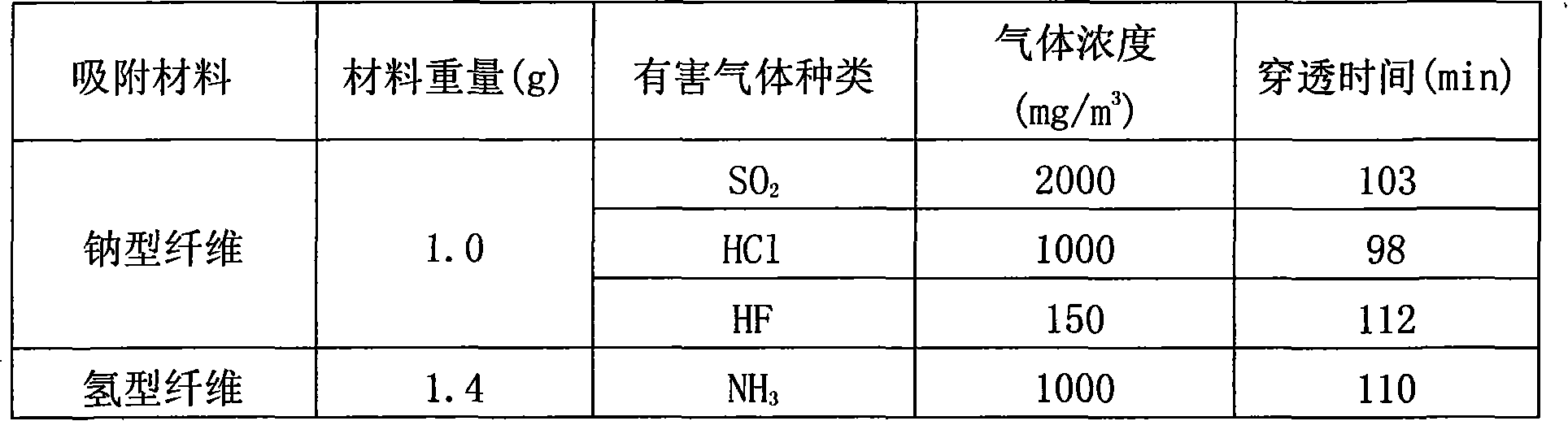

Examples

Embodiment 1

[0026] Embodiment 1: add 1% sodium hydroxide solution 100kg, acrylic fiber 3kg in reactor, with reactor airtight, heat while stirring, make reaction be that 140 ℃ of temperature, pressure are under the condition of 0.4MPa reaction 1 Hours, then lower the temperature, discharge, wash and dry to obtain sodium-type ion-exchange fibers.

[0027] Add 100kg of 5% hydrochloric acid and the above-mentioned sodium-type ion-exchange fibers into an open container, transform for 6 hours, and then wash and dry to obtain hydrogen-type ion-exchange fibers.

Embodiment 2

[0028] Example 2: Add 100 kg of 3% sodium hydroxide solution and 3 kg of acrylic fiber fibers to the reactor, close the reactor, stir and heat, react for 3 hours at 120 ° C and 0.2 MPa, cool down and discharge, wash and dry, Get sodium ion exchange fiber.

[0029] Add 100 kg of 5% nitric acid solution and the above-mentioned sodium-type ion-exchange fibers to an open container, transform for 10 hours, wash and dry to obtain hydrogen-type ion-exchange fibers.

Embodiment 3

[0030] Example 3: 100 kg of 10% sodium hydroxide solution and 3 kg of acrylic fiber fibers were added to the reaction kettle, and the closed reaction kettle was stirred and heated, and reacted for 4 hours at 110 ° C and 0.1 MPa, cooled and discharged, washed and dried to obtain sodium type ion exchange fibers.

[0031] Add 100 kg of 5% sulfuric acid solution and the above-mentioned sodium-type ion-exchange fibers into an open container, transform for 5 hours, wash and dry to obtain hydrogen-type ion-exchange fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com