Method for producing printing cream for electrode jump absorption, laminating ceramics electronic component

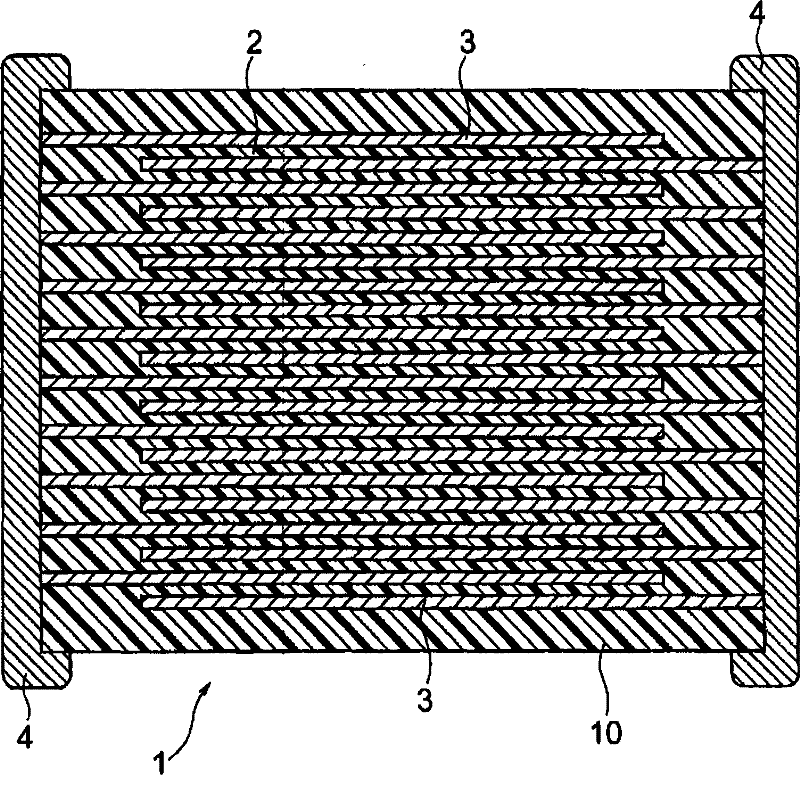

A technology of electronic components and printing paste, which is applied in the field of printing paste for electrode step absorption, which can solve the problems of sheet erosion and achieve the effects of preventing sheet erosion, improving peelability, and reducing short-circuit faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0109] As mentioned above, although embodiment of this invention was described, this invention is not limited to the said embodiment, Various changes are possible in the range which does not deviate from the summary of this invention.

[0110] For example, the above embodiments exemplify multilayer ceramic capacitors as the multilayer ceramic electronic components of the present invention, but the multilayer ceramic electronic components of the present invention are not limited to multilayer ceramic capacitors, and can of course be applied to multilayer ceramic substrates and the like.

Embodiment 1

[0114] First, a butyral resin-containing dielectric paste for forming a ceramic green sheet using a butyral resin (polyvinyl butyral) as an organic binder was prepared.

[0115] Preparation of Dielectric Paste Containing Butyral Resin

[0116] Prepare BaTiO 3 Ceramic powder, polyvinyl butyral (PVB) as an organic binder, and methanol as a solvent. Then, 10 parts by weight of the organic binder and 150 parts by weight of the solvent were weighed with respect to 100 parts by weight of the ceramic powder, and kneaded and slurried by a ball mill to obtain a butyral resin-containing dielectric paste.

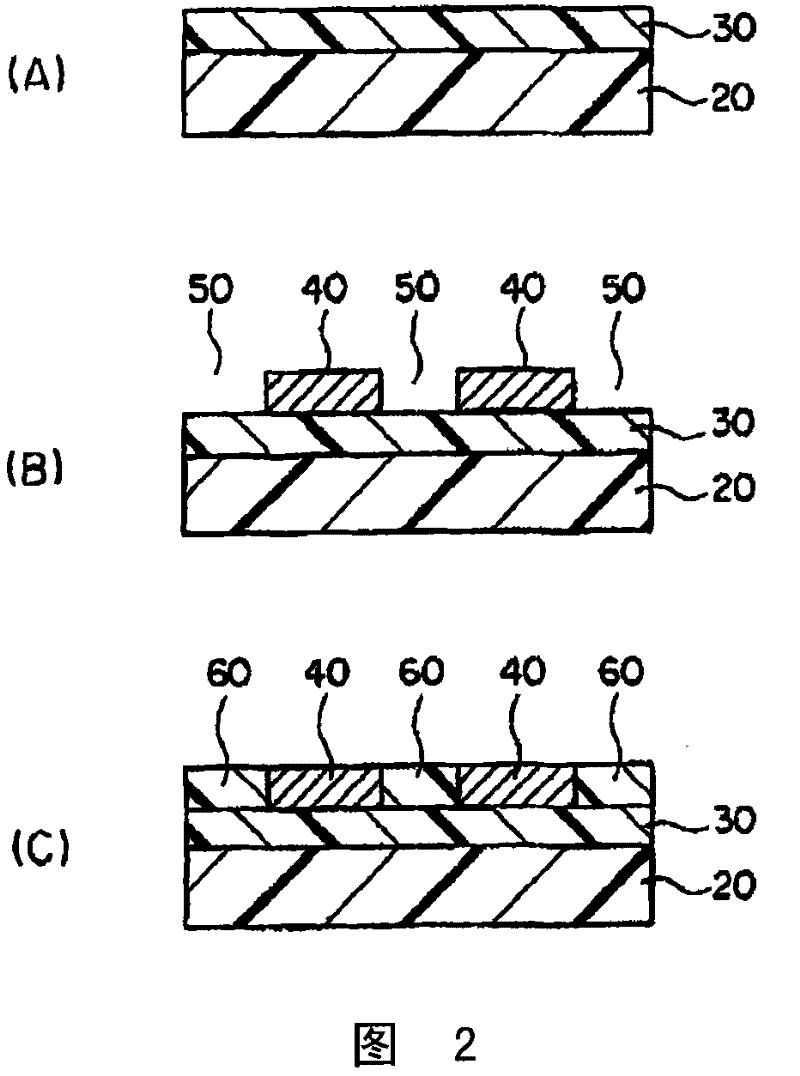

[0117] Fabrication of Ceramic Green Sheets Containing Butyral Resin

[0118] The above-mentioned dielectric paste was applied to a predetermined thickness on a PET film by a doctor blade method, and dried to form a butyral resin-containing ceramic green sheet having a thickness of 1.5 μm after drying.

[0119] Compatibility test of solvent and ceramic chip containing butyral ...

Embodiment 2

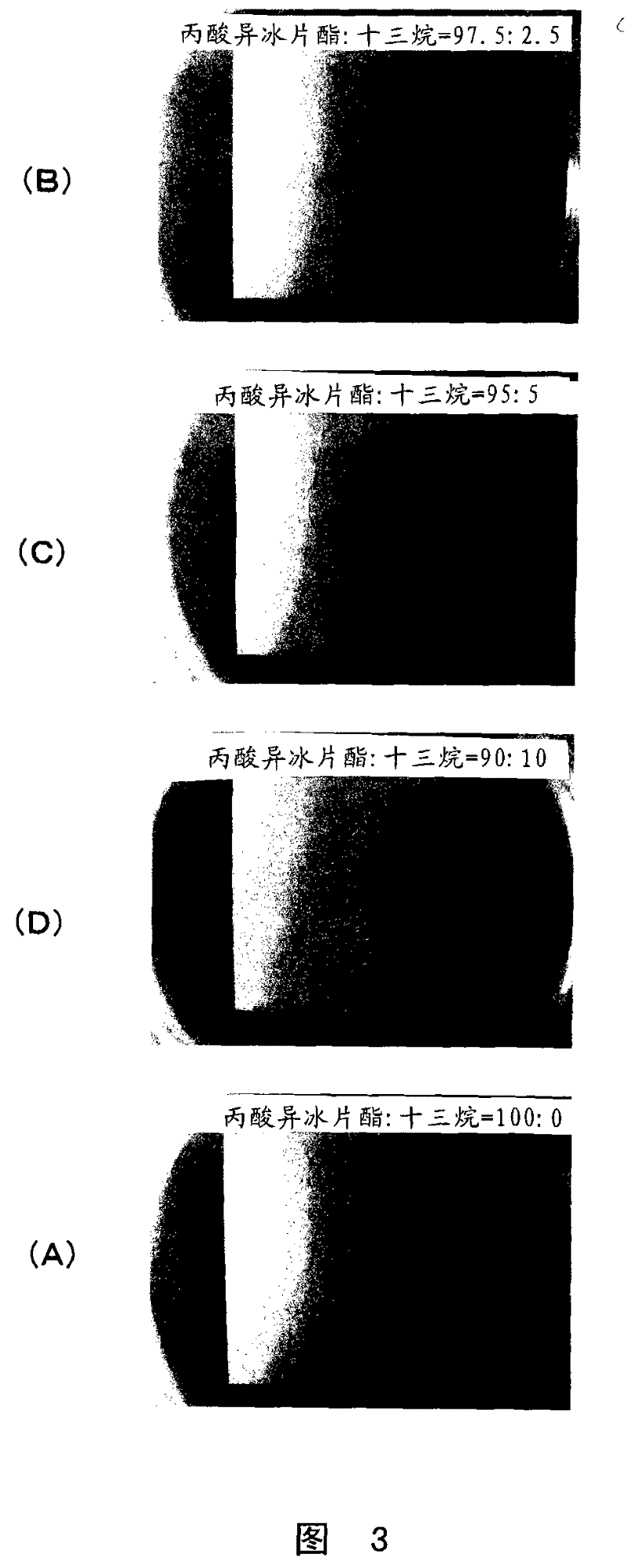

[0127] Compatibility test of solvent and ceramic green sheet containing acrylic resin (50°C, dipping)

[0128] Except using acrylic resin as the organic binder, operate in the same manner as in Example 1 to make a dielectric paste containing acrylic resin and a ceramic green sheet containing acrylic resin. Compatibility test of green sheet (50°C, immersion).

[0129] In addition, in Example 2, various solvents shown in Table 2 below were used as solvents, and photographs of acrylic resin-containing ceramic green sheets dipped in the respective solvents were shown in each figure described in Table 2, respectively.

[0130] Table 2

[0131] solvent microscope photo Isobornyl propionate: tridecane = 100:0 Figure 5 (A) Isobornyl propionate: tridecane = 97.5: 2.5 Figure 5 (B) Isobornyl propionate: tridecane = 95:5 Figure 5 (C) Isobornyl propionate: tridecane = 90:10 Figure 5 (D)

[0132] Depend on Figure 5 (B)~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com